Repairing coating

A coating and sealing technology, which is applied in the field of sealing coatings, can solve problems such as poor sealing quality, and achieve the effects of preventing wet film from sagging, reducing viscosity, and increasing hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of sealing paint, wherein the base material comprises the following components according to weight percentage:

[0033] Liquid bisphenol A epoxy resin (type 127 / 128) 280

[0034] Liquid bisphenol F epoxy resin (model EF170) 75

[0035] Xylene 45

[0036] Polyimide (epoxy toughener) 110

[0038] Kaolin 200

[0040] Fumed silica (thixotropic agent) 20

[0041] Titanium dioxide 30

[0042] Carbon black 0.8

[0043] Triethylenetetramine (curing agent)

[0044] The ratio of base material to curing agent is: base material: curing agent = 100:23.

[0045] Base preparation:

[0046] After weighing each component of the base material according to the formula, add it to the grinder for grinding until the fineness of the coating is less than 80um.

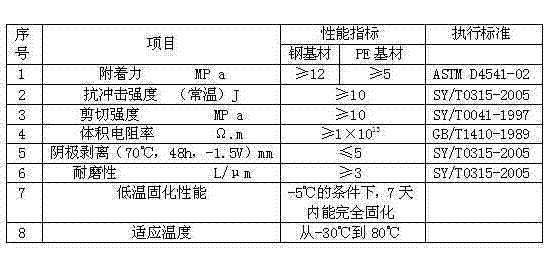

[0047] The main performance index of the patch coating coating of this embodiment 1 is shown in the following table 1:

[0048]

[0049] In addition, through ...

Embodiment 2

[0051] The base material of the filling paint comprises the following components according to weight percentage:

[0052] Liquid bisphenol A epoxy resin (type 127 / 128) 290

[0053] Liquid bisphenol F epoxy resin (model EF170) 80

[0054] Toluene 50

[0055] Nitrile rubber (epoxy toughener) 100

[0057] Kaolin 180

[0059] Organic bentonite (thixotropic agent) 30

[0060] Titanium dioxide 35

[0061] Carbon black 0.7

[0062] Diethylenetriamine (curing agent)

[0063] The ratio of base material to curing agent is: base material: curing agent = 100:23.

[0064] The preparation method of base material is with embodiment 1.

[0065] The sealing coating performance test result of embodiment 2 is shown in Table 2:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com