Process for manufacturing heat insulation decoration board

A technology for a thermal insulation decorative panel and a manufacturing method, applied in the field of building decorative materials, can solve the problems of difficult quality control, manual on-site operation, and large potential safety hazards, and achieve the effects of simplifying the on-site construction process, shortening the construction period, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Guangte calcium silicate board for veneer: 1200×2400×6mm, thermal conductivity 0.28W / (M.K), density 1.0g / cm 3 . Shenzhen Kejia Industrial Co., Ltd. extruded board for insulation layer: 1200×2400×6mm, density 18.5kg / m 3 , the thermal conductivity is 0.030 W / (M.K), and the non-combustibility is B1 level, in line with GB624-1997. The adhesive is PU550 from Taiwan Jinyi Trading Company, and the shear strength is >6MPa (aluminum / aluminum material) after curing for 7 days. The top coat for painting is CMY8709-4001YV fluorocarbon coating produced by Shenzhen Mingyuan Fluorocoating Co., Ltd. Produce the finished board according to the above process.

example 2

[0028] Fiber cement board (cardboard) of Jiangsu Aifuxi New Building Materials Co., Ltd. for decorative panels: 1200×2400×6mm, density 1.4g / cm 3 , thermal conductivity 0.40W / (M.K), non-combustibility is Class A (GB8624-1997). Extruded board of Shenzhen Kejia Company for insulation layer: 1200×2400×3mm, density 18.5kg / m 3 , the thermal conductivity is 0.030W / (M.K), and the non-combustibility is B1 level (GB8624-1997). The adhesive uses PU550 from Taiwan Jinyi Trading Company. The top coat for painting is CMY8709-4001YV fluorocarbon coating produced by Shenzhen Mingyuan Fluorocoating Co., Ltd. Produce the finished board according to the above process.

example 3

[0030] Calcium silicate board (LCFC) of Jiangsu Aifuxi New Building Materials Co., Ltd. for decorative panels: 1200×2400×4mm, density 1.1g / m 3 , the thermal conductivity is 0.28 W / (M.K), and the non-flammability is Class A (GB8624-1997). The adhesive uses PU550 from Taiwan Jinyi Trading Company. The insulation layer is extruded board from Shenzhen Kejia Industrial Development Company: 1200×2400×6mm, density 18.5kg / m 3 , the thermal conductivity is 0.030W / (M.K), and the non-combustibility is B1 level (GB8624-1997). The paint used for painting is CMY8809-0000V produced by Shenzhen Mingyuan Fluorine Coatings Co., Ltd. The finished board is made by the above-mentioned process.

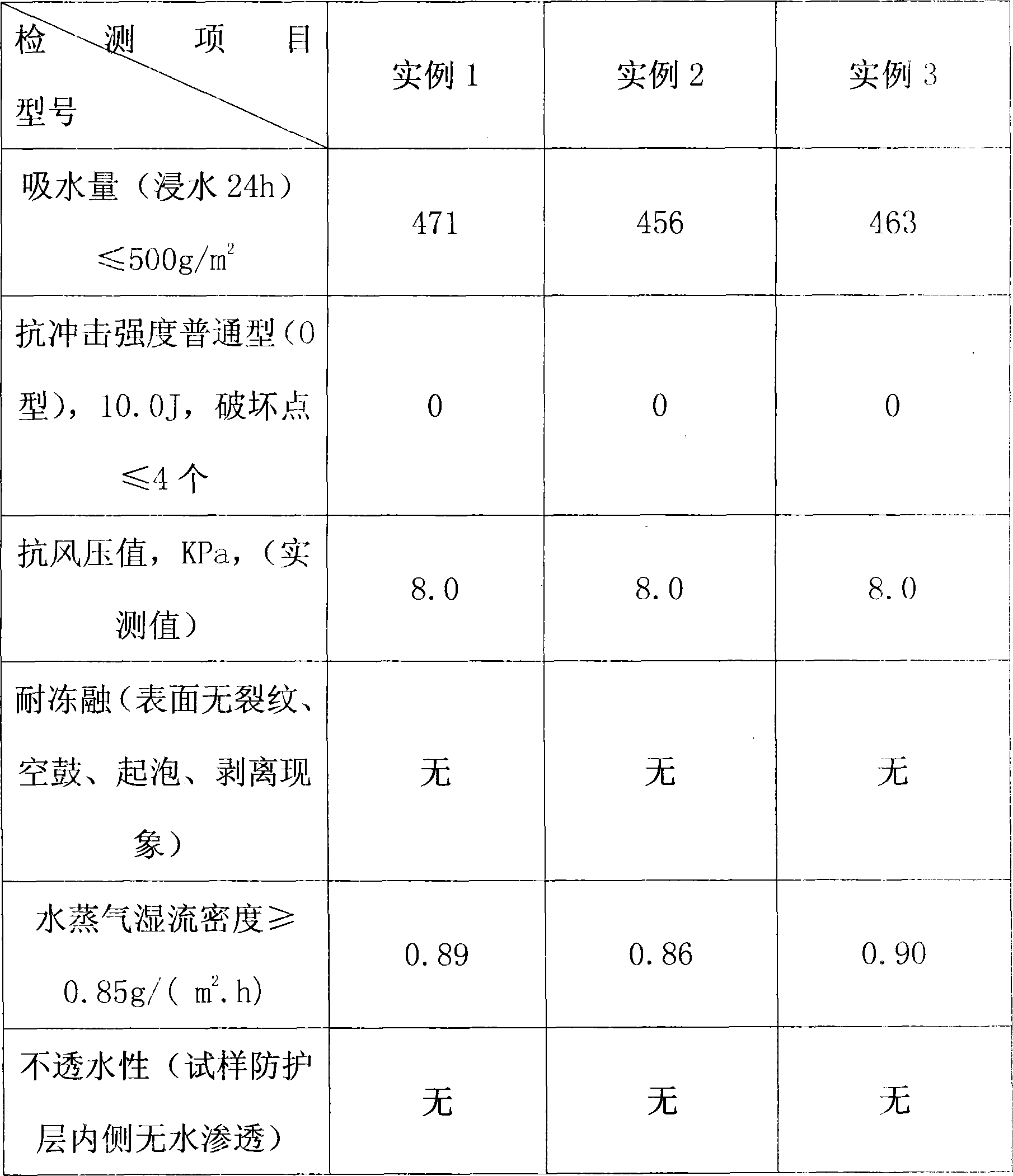

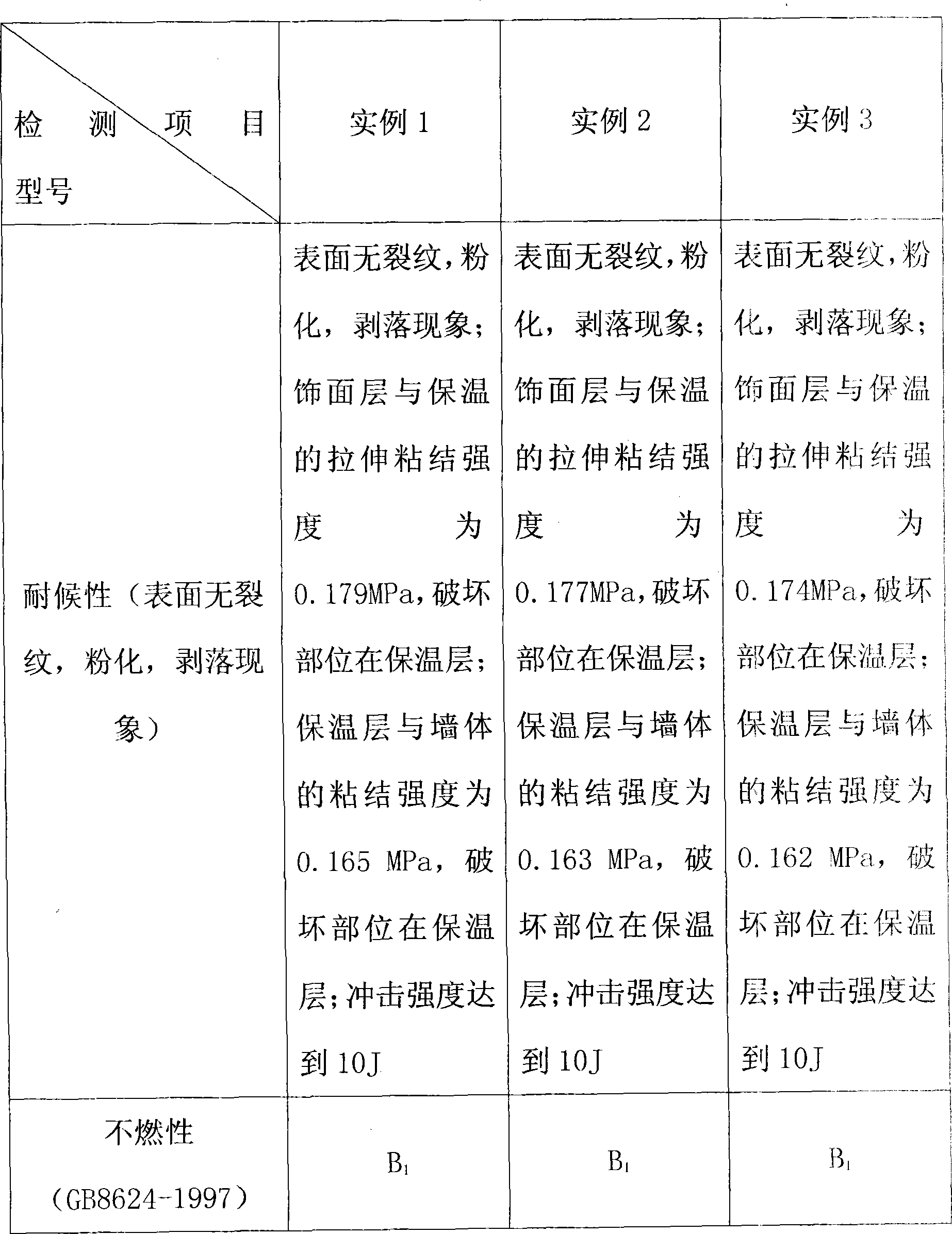

[0031] The boards were randomly selected from the above three examples, and tested according to JGJ144-2004 technical regulations for external wall thermal insulation engineering and JG149-2003 expanded polystyrene board thin plaster external wall thermal insulation system, and the test results are show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| processing temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com