A high-temperature resistant solid-free microfoam drilling fluid or completion fluid

A technology of high temperature resistance and drilling fluid, applied in the field of drilling fluid and completion fluid, which can solve the problems of low temperature resistance of solid-phase micro-foam drilling fluid system, difficulty in protection, discovery of oil and gas layers, and poor foam uniformity. , to achieve the effect of excellent leakage prevention and plugging ability, simplifying on-site construction technology, and strong rock-carrying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] ⑴ 0.5 part of high temperature resistant tackifier SL-DT, composed of HV-CMC: OCL-PTN=3:5 ratio; ⑵ 0.6 part of high temperature resistant foaming agent SL-DF, which is high temperature resistant modified tea saponin ZY- GW; (3) anti-high temperature protective agent SL-DI 0.2 parts Span 80: Tween 80=1:3 ratio composition; (4) anti-high temperature fluid loss additive SL-JL 2.3 parts, composed of anti-high temperature fluid loss additive OCL-JA : Lignite resin SPNH: sulfomethyl phenolic resin SMP-II=5:3:1.5 ratio; ⑺100 parts of water.

[0053] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~1000 revolutions / min), add the components ⑺ sequentially in a conventional way, stir for 4 hours after all the addition, and test Its rheological properties, fluid loss properties and half-life. Then, the microfoam drilling fluid was poured into a high-temperatur...

Embodiment 2

[0055] ⑴ 0.6 parts of high temperature resistant tackifier SL-DT, composed of HV-CMC: OCL-PTN=5:9 ratio; ⑵ 0.8 parts of high temperature resistant foaming agent SL-DF, which is high temperature resistant modified tea saponin ZY- GW; (3) anti-high temperature protective agent SL-DI 0.2 parts Span 80: Tween 80=2:4 ratio composition; (4) anti-high temperature fluid loss additive SL-JL 2.5 parts, composed of anti-high temperature fluid loss additive OCL-JA : lignite resin SPNH: sulfomethyl phenolic resin SMP-II = 6:5:2 ratio; ⑺100 parts of water.

[0056] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~1000 revolutions / min), add the components ⑺ sequentially in a conventional way, stir for 4 hours after all the addition, and test Its rheological properties, fluid loss properties and half-life. Then, the microfoam drilling fluid was poured into a high-temperat...

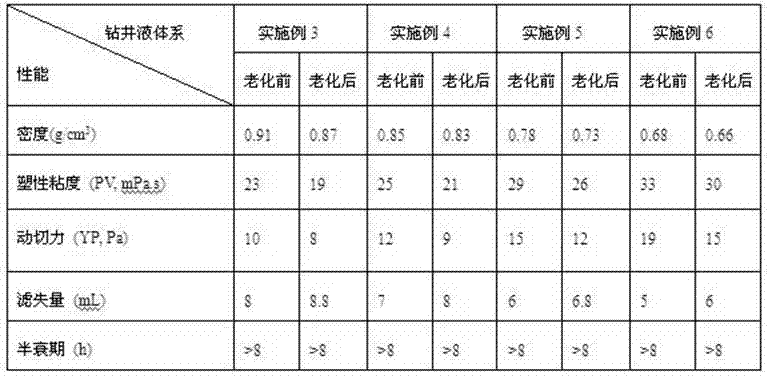

Embodiment 3

[0058] ⑴High temperature resistant tackifier SL-DT, 0.5 parts, composed of HV-CMC:OCL-PTN=2:3 ratio; ⑵High temperature resistant foaming agent, SL-DF 0.5 parts, high temperature resistant modified tea saponin ZY-GW; ⑶ anti-high temperature protective agent, SL-DI 0.2 parts Span 80: Tween 80 = 1:2 ratio; Agent OCL-JA: lignite resin SPNH: sulfomethyl phenolic resin SMP-II = 5:2:1 ratio; 0.2 parts of soda ash; (⑺) 100 parts of water.

[0059] Preparation method: the above-mentioned components ⑴-⑹ according to their content, under normal temperature and pressure, under the condition of mechanical stirring (600~1000 revolutions / min), add the components ⑺ sequentially in a conventional way, stir for 4 hours after all the addition, and test Its rheological properties, fluid loss properties and half-life. Then, the microfoam drilling fluid was poured into a high-temperature aging tank, aged at 200°C for 16 hours, and then the properties of the microfoam drilling fluid (rheology, flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com