Spray maintenance telescopic spray head

A technology of nozzles and water nozzles, which is applied in the direction of spraying devices, spraying devices, spraying devices with movable outlets, etc., which can solve the problems of increasing the difficulty of erecting and dismantling formwork, affecting the structural strength of cast-in-place components, and reducing construction efficiency. , to achieve the effect of reducing site occupancy rate, saving construction difficulty and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

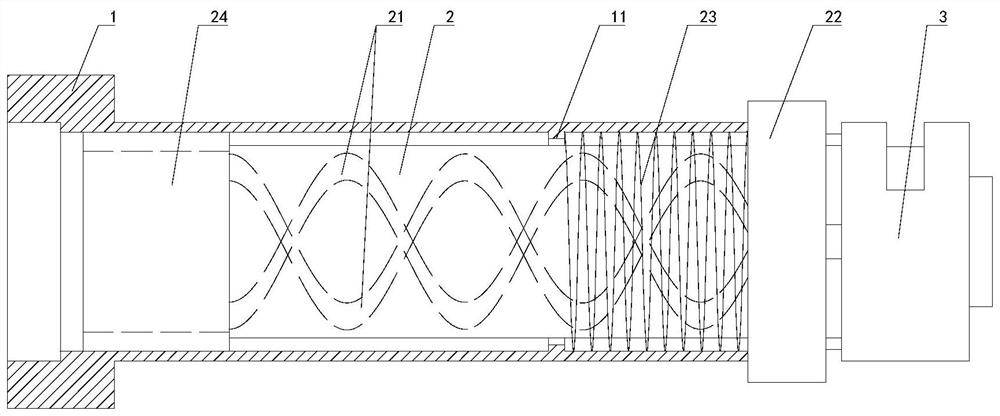

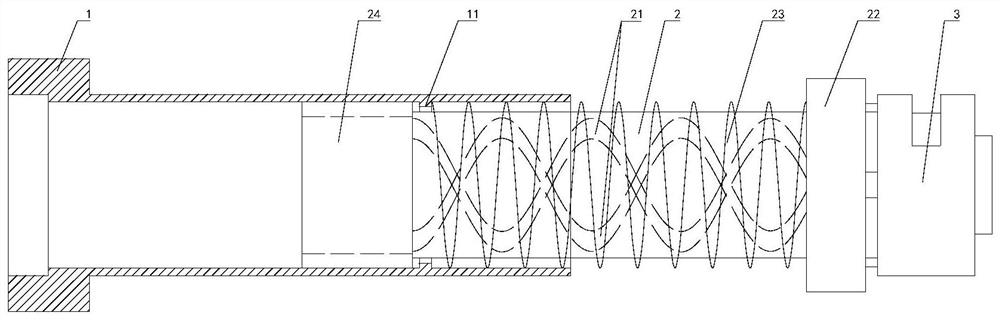

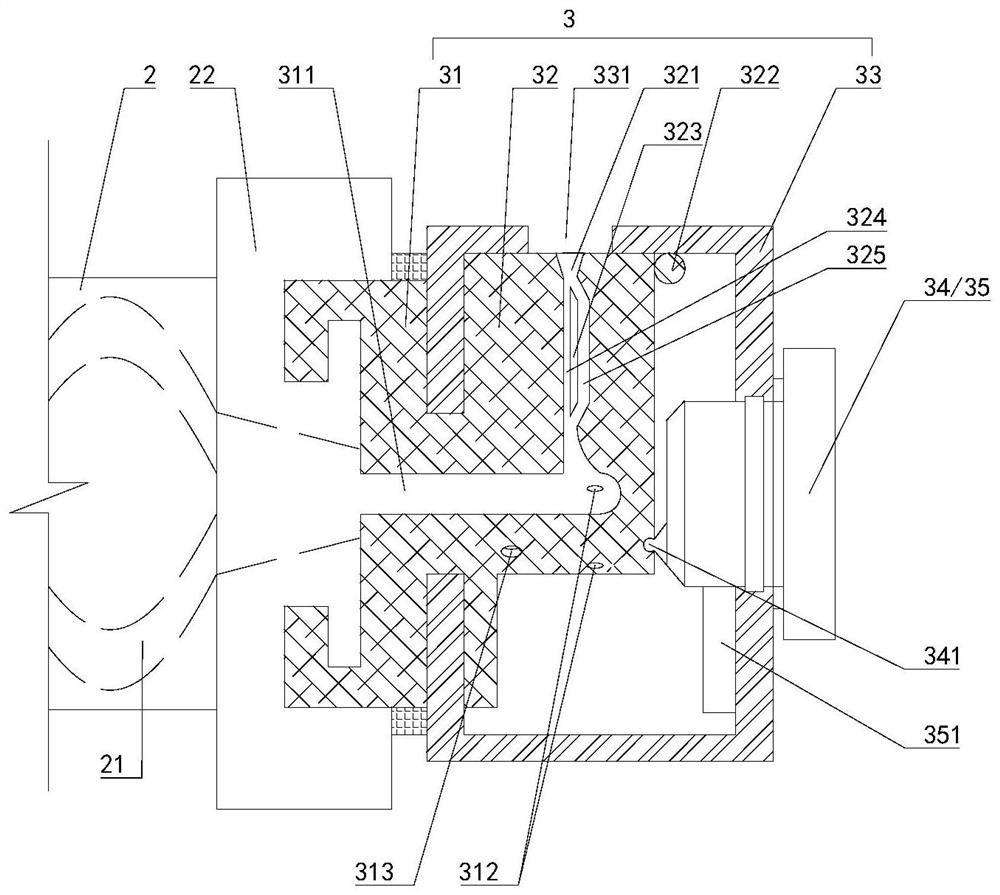

[0024] as attached figure 1 , attached figure 2 As shown, the embodiment of the present invention proposes a telescopic nozzle for spray maintenance, including a connecting pipe 1, which is connected to a water supply pipe, and a sliding body 2 is slidably connected in the connecting pipe 1. Under the action of water pressure, Part of the sliding body 2 protrudes from the connecting pipe 1. Under the action of no water pressure, the sliding body 2 shrinks in the connecting pipe 1. There is a water channel 21 inside the sliding body 2. The end of the sliding body 2 is rotatably connected to the nozzle device 3. The nozzle device 3 communicates with the water passage 21, and the nozzle device 3 swings left and right with the central axis of the sliding body 2 as the rotation axis under the action of water pressure.

[0025] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com