Attraction material device and manufacturing method thereof

A manufacturing method and a technology of absorbing materials, which are applied in lamination devices, chemical instruments and methods, lamination auxiliary operations, etc., can solve the problems of large investment in batch production equipment, low efficiency of molding production methods, and high requirements for process equipment. , to achieve good UV light blocking and chemical resistance, good flatness, and less space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The suction material device of the present invention includes a suction part and a suction part, the suction part is composed of a base plate and a magnet embedded in the base plate, the magnets are distributed in parallel in several rows and columns in the base plate, and the base plate of the suction part still has magnets in the base plate A magnet / iron sheet combination is embedded on one side. The joint part is composed of a base plate and an iron sheet embedded in the base plate.

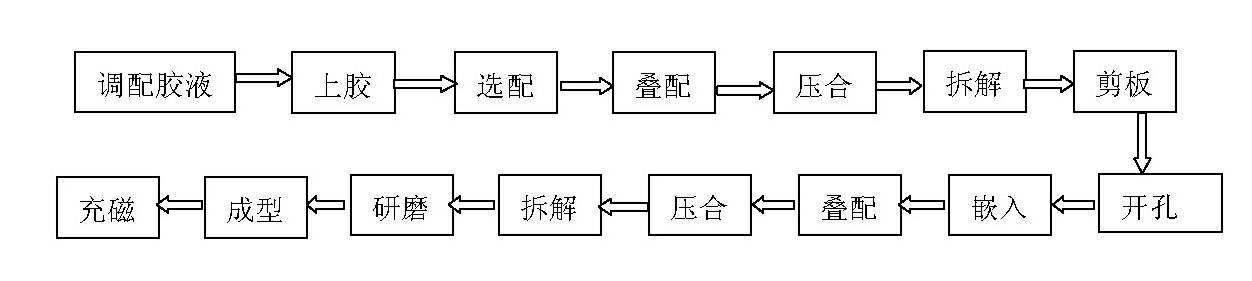

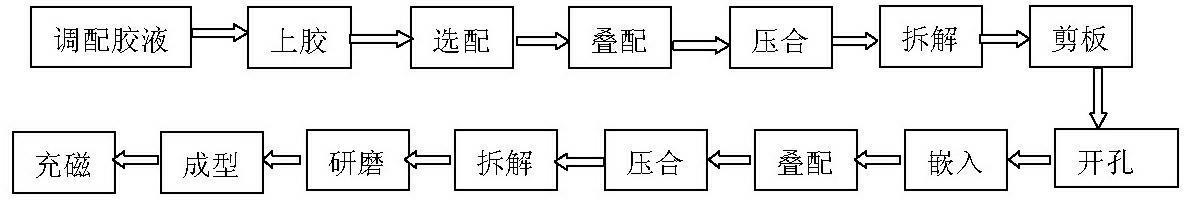

[0033] refer to figure 1 , the manufacturing method of the suction device material comprises the following steps:

[0034] 1. 133g of bisphenol A epoxy resin, 5.7g of tetrafunctional epoxy resin, 2.8g of electronic grade dicyandiamide, 0.046g of dimethylimidazole, 20g of 10-micron aluminum hydroxide, and 30g of dimethylformamide were prepared into a gel Glue for 250-255 seconds;

[0035] 2. Immerse 7628 cloth and 2116 cloth in glue solution and bake in an oven with a temperature of ...

Embodiment 2

[0049] refer to figure 1 , the manufacturing method of this suction device material comprises the following steps:

[0050] 1. 133g of bisphenol A epoxy resin, 5.7g of tetrafunctional epoxy resin, 2.9g of electronic grade dicyandiamide, 0.046g of dimethylimidazole, 20g of 10-micron aluminum hydroxide, and 29g of dimethylformamide were prepared into a gel Glue for 250-255 seconds;

[0051] 2. Immerse the 7628 cloth in the glue solution and bake it in an oven with a temperature of 180℃-220℃, and then cool it to obtain a 7628 cloth prepreg with a gel time of 120-125 seconds and a resin content of 44.1%-44.9%. Cut the 7628 cloth prepreg into the required size;

[0052] 3. When matching, stack 4 pieces of 7628 cloth prepregs together;

[0053] 4. After the prepreg stacked in step 3 is covered with release film on both sides, a certain number of stacked plates and stainless steel plates are stacked one-to-one and sent to a vacuum press for pressing. Press between 165°C, the hol...

Embodiment 3

[0065] refer to figure 1 , the manufacturing method of the suction device material comprises the following steps:

[0066] 1. 133g of bisphenol A epoxy resin, 5.7g of tetrafunctional epoxy resin, 2.8g of electronic grade dicyandiamide, 0.044g of dimethylimidazole, 20g of 10-micron aluminum hydroxide, and 30g of dimethylformamide were prepared into a gel Glue with a time of 253-258 seconds;

[0067] 2. The 7628 cloth and 1506 cloth are soaked in the glue solution, put into an oven with a temperature of 180℃-220℃, and then cooled to obtain 7628 with a gel time of 122-127 seconds and a resin content of 44.1%-44.9%. Cloth prepreg and 1506 non-preg with gel time of 122-127 seconds and resin content of 42.6%-43.4%, cut 7628 cloth prepreg and 1506 cloth prepreg into the required size;

[0068] 3. When matching, stack 4 pieces of 7628 cloth prepregs together;

[0069] 4. The prepreg laminated in step 3 is covered with release film on both sides, and then the laminated sheets are l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com