Walking type pipe gallery formwork supporting device

A formwork-supported, walking-type technology, applied in the direction of shaft equipment, shaft lining, tunnel lining, etc., can solve the problems of poor civilized construction, long construction period, low operation efficiency, etc., to facilitate operation inspection, improve operation efficiency and assembly speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

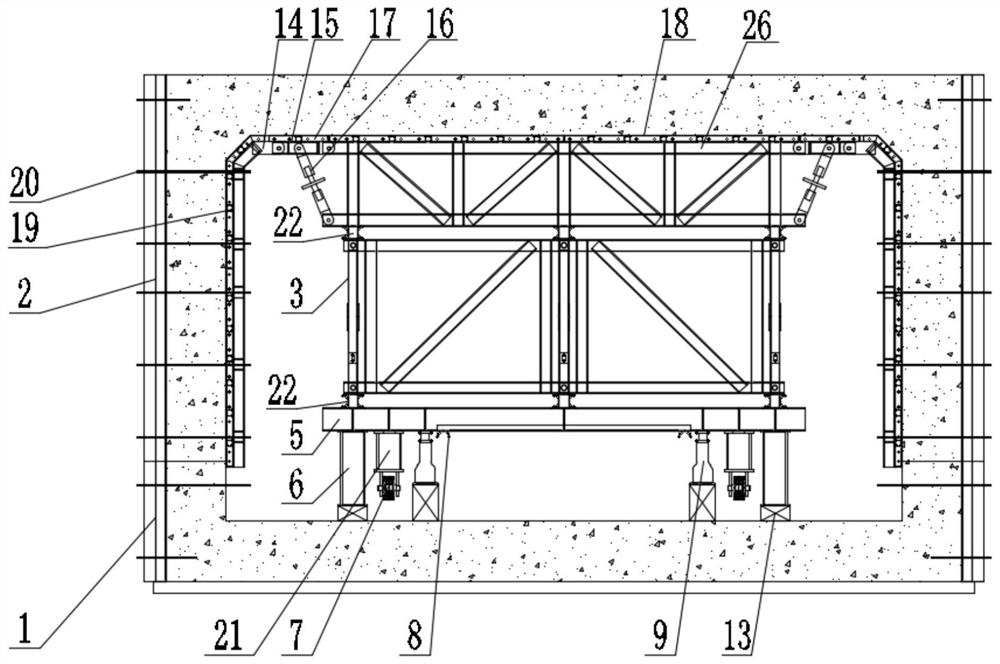

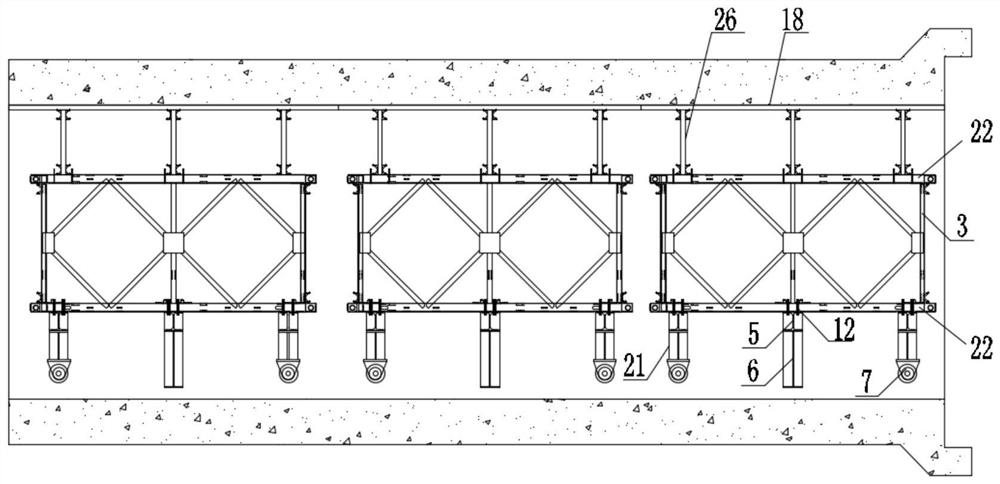

[0063] like Figure 8 As shown, the present invention is used to carry out the construction of the three-storey underground comprehensive pipe gallery.

[0064] The wide warehouse is supported by wide cars, and the two narrow warehouses are supported by narrow cars. The wide car is the supporting device for the aforementioned walking pipe gallery formwork. Compared with the aforementioned walking type pipe gallery formwork support device, the narrow car saves the beam extension joint 15 and the length-adjustable diagonal brace 16 .

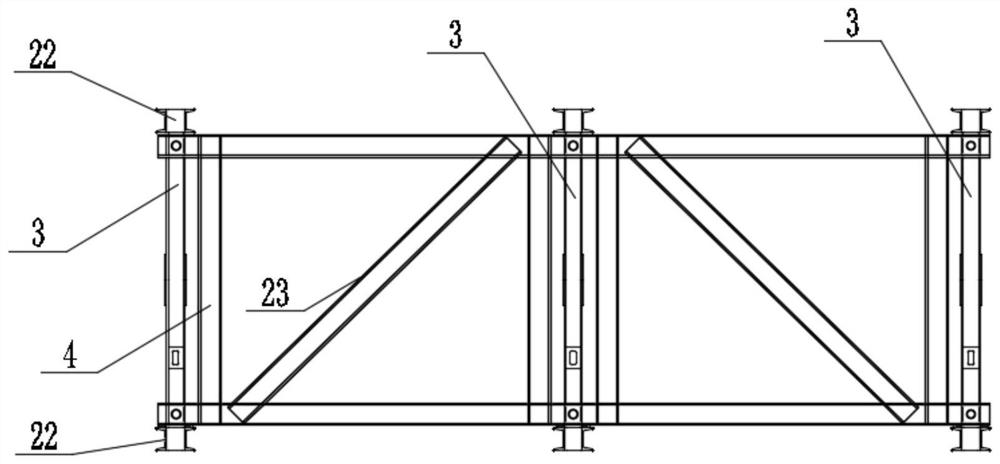

[0065] like Figure 9 As shown, the structure of the Bailey frame body of the narrow car is more streamlined, and the body includes the Bailey sheet 24 and the Bailey sheet connection 25.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com