Isolation type double-lining shield tunnel construction structure and construction method

A technology for shield tunneling and construction methods, which is applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of long overall construction period, influence of secondary lining structure, and high construction cost, so as to reduce damage, solve the influence of cross-interference, and improve The effect of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

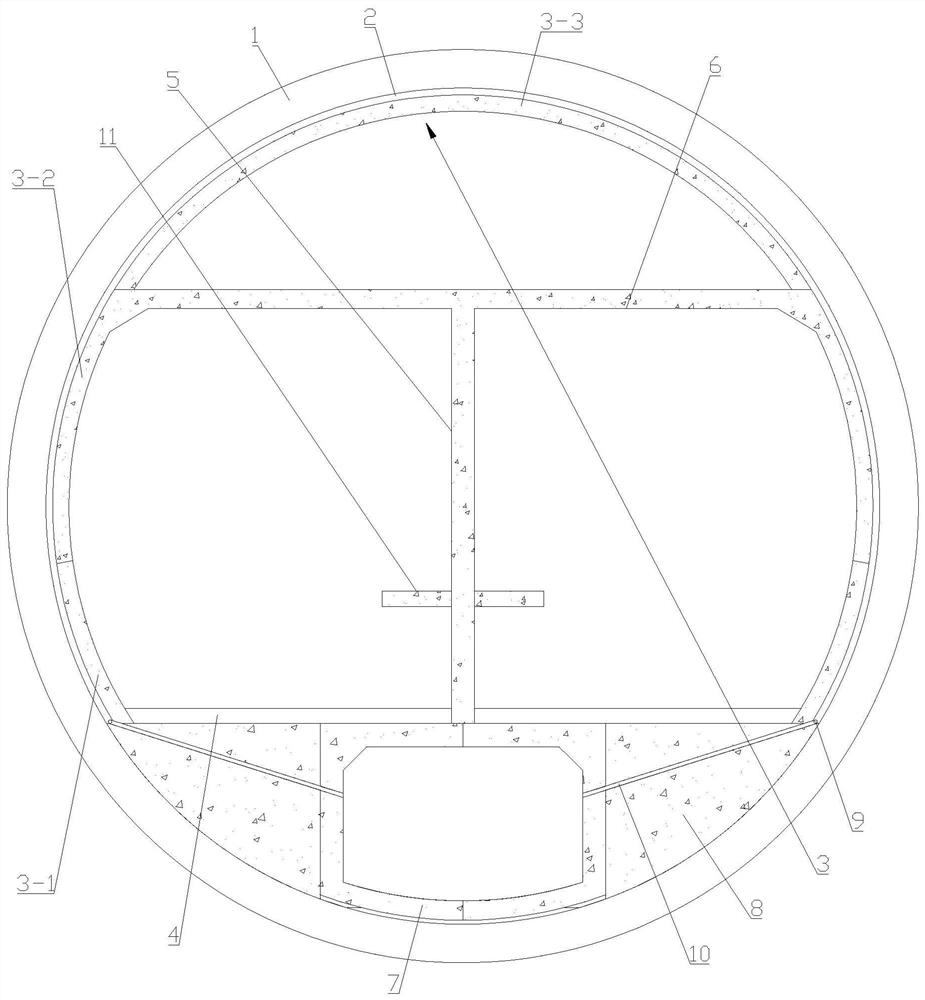

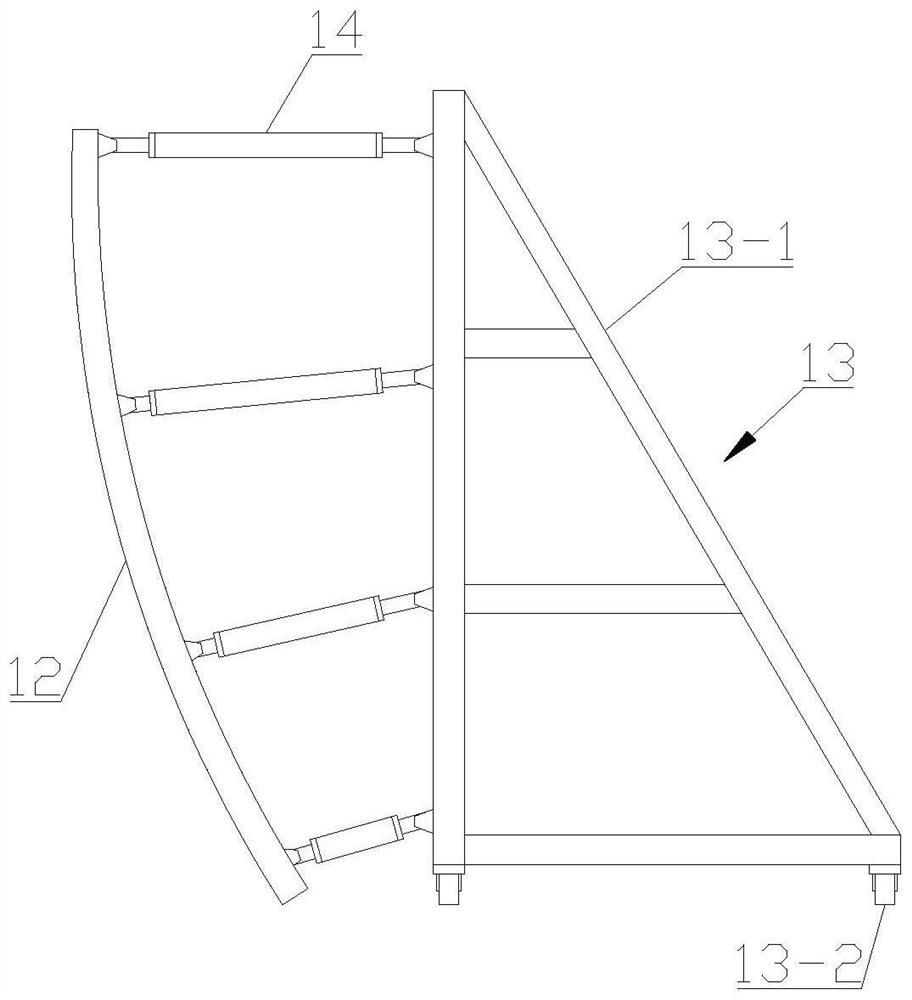

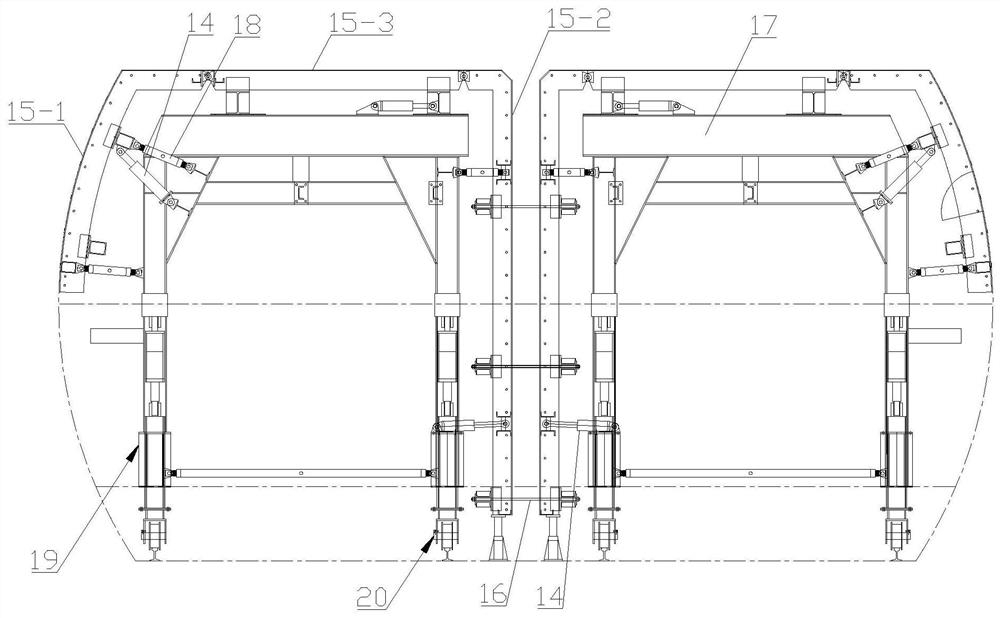

[0053] Such as figure 1 The construction structure of an isolated double-lined shield tunnel shown includes a primary lining 1 arranged in the tunnel body, a secondary lining 3 and an inverted arch screed 4 arranged in the primary lining 1, and the primary lining 1 Including multi-ring segments, the inverted arch leveling plate 4 is arranged between the bottoms of the two sides of the secondary lining 3, an isolation buffer layer 2 is provided between the primary lining 1 and the secondary lining 3, and the inverted arch leveling The flat plate 4 is provided with a partition wall 5, the partition wall 5 is provided with an air channel plate 6, and the bottom of the inverted arch flat plate 4 is provided with an opening box culvert 7 and an inverted arch filling layer 8, and the opening The box culvert 7 includes a plurality of prefabricated openings, and the bottom of both sides of the isolation buffer layer 2 is respectively provided with a water collecting pipe 9, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com