'n' shaped element mold for precasting reinforced concrete culvert

A reinforced concrete and mold technology, applied in the direction of molds, mold separation devices, etc., can solve the problems of concrete slurry leakage, template deformation, and difficulty in tightly combining the joints between plates and plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

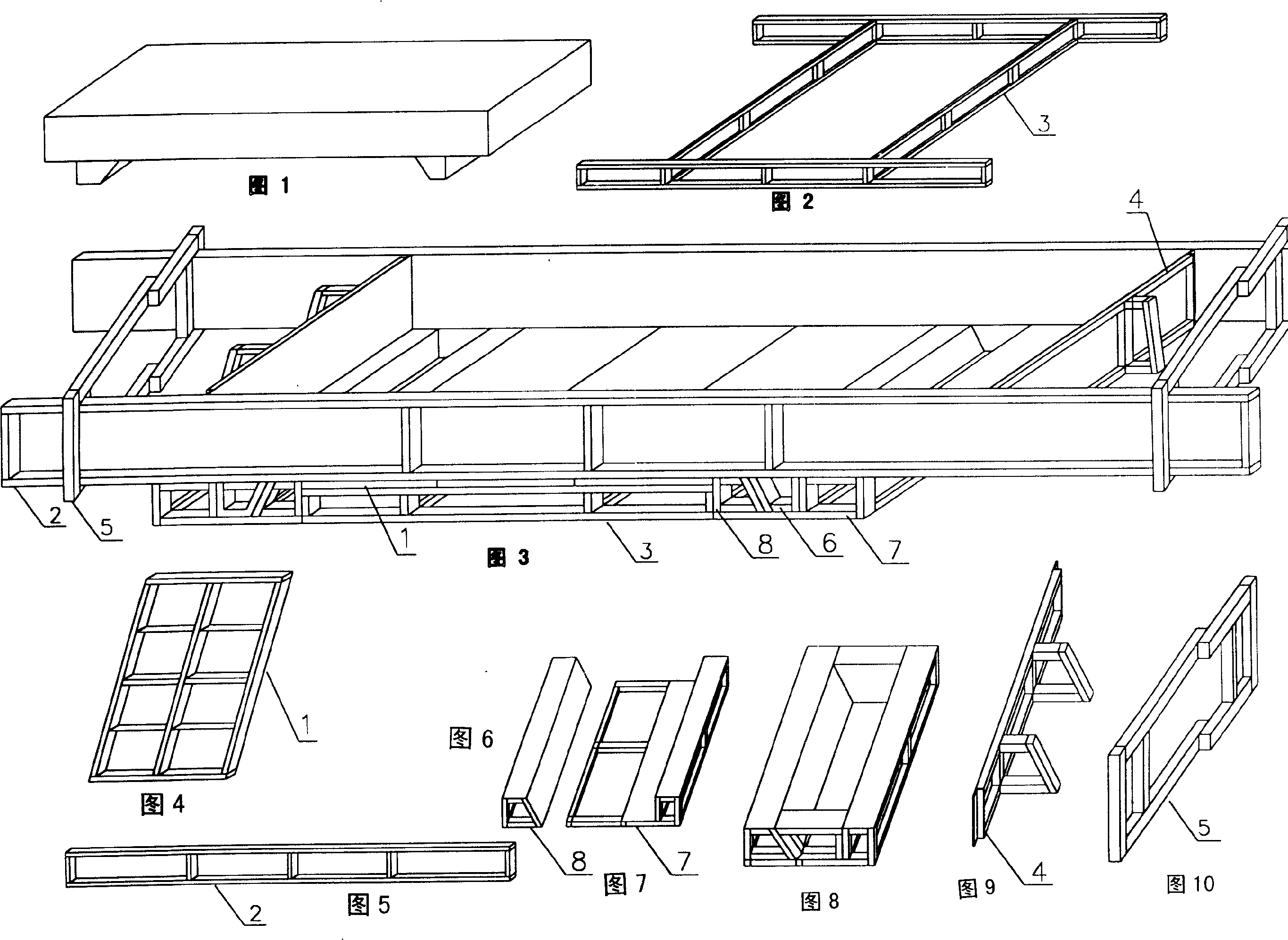

[0018] The mold of the -shaped member of the present invention. The side mold of the "" plate is formed by combining the side mold (2), the side mold with support (4) and the side plate fixing frame (5). Block formwork (6), chair-shaped bottom plate formwork (7), trapezoidal bottom formwork (8), base plate (1), bracing frame (3) form bottom supporting formwork system, are installed in the below of mold frame formwork. Side mold (4) is bolted on the chair-shaped base plate form (7), and side mold forms the complete set of mold (as shown in Figure 3) of producing -shaped plate together with bottom supporting formwork system. Base plate (1) is the similar " field " shape skeleton that is welded into by square steel pipe, also can add welding flat steel in skeleton, cover welding steel plate at one side of skeleton, so that bolt is connected with side form in its proper position drilling. Side formwork (2) is the skeleton similar to " day " " mesh " font that is welded into by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com