Ribbed prefabricated member template for building

A technology for prefabricated components and construction, applied in the direction of molds, etc., can solve problems such as low construction efficiency, difficult formwork removal, and cumbersome production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

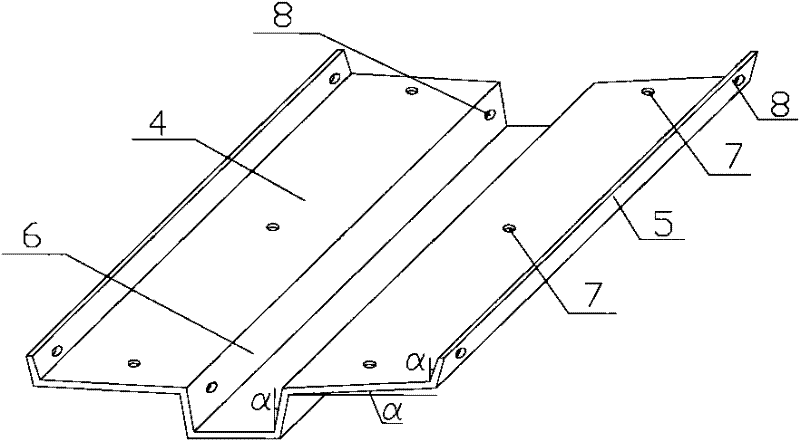

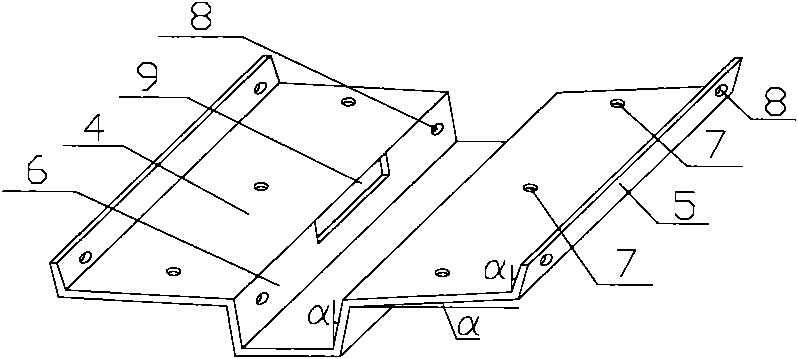

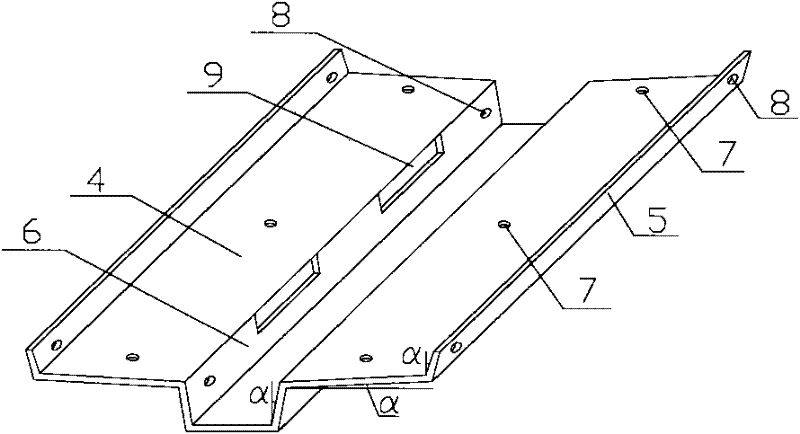

[0024] As shown in the accompanying drawings, the present invention is a ribbed prefabricated component formwork for construction. The ribbed prefabricated component formwork for construction is assembled from one or more than one module 1. The module 1 includes a base plate bottom form 4 and a base plate side formwork 5. And longitudinal rib sideform 6. The present invention is characterized in that: the base plate base form 4 of the module 1 has an included angle α with the horizontal plane, the base plate side form 5 and the longitudinal rib side form 6 have an included angle α with the vertical plane, and α≥5°. Due to the existence of the included angle α, under the action of the bolt force, the formwork and the ribbed prefabricated component are more easily separated, which facilitates the removal of the whole ribbed prefabricated component formwork. When assembling the ribbed prefabricated component formwork for construction, the modules 1 are docked and placed, and fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com