Ribbed precast component template for buildings

A technology for prefabricated components and construction, applied in the direction of molds, etc., can solve problems such as low construction efficiency, difficult formwork removal, and cumbersome production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

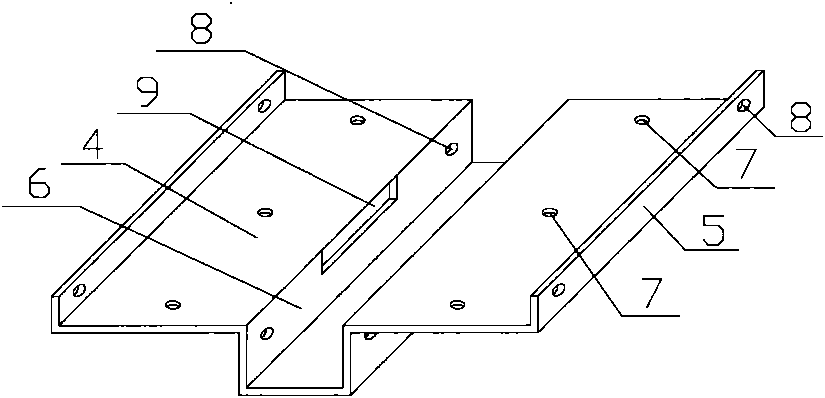

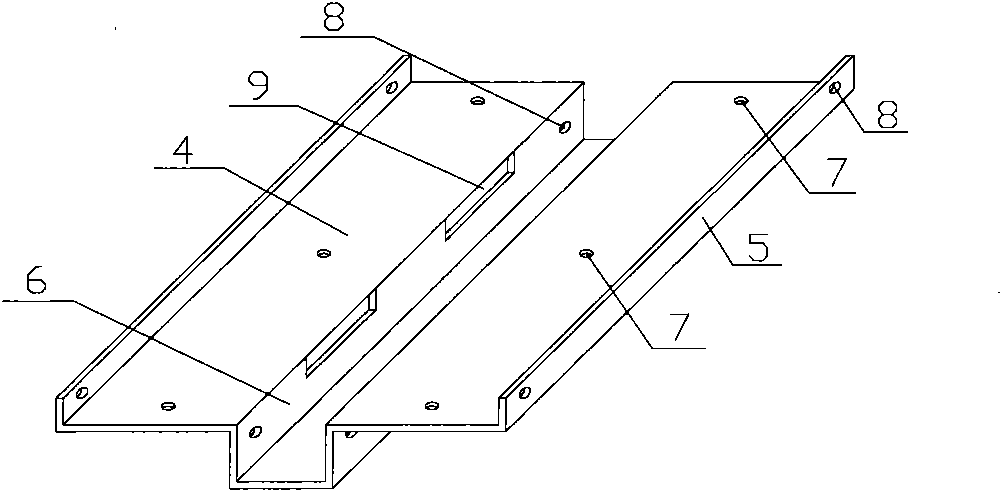

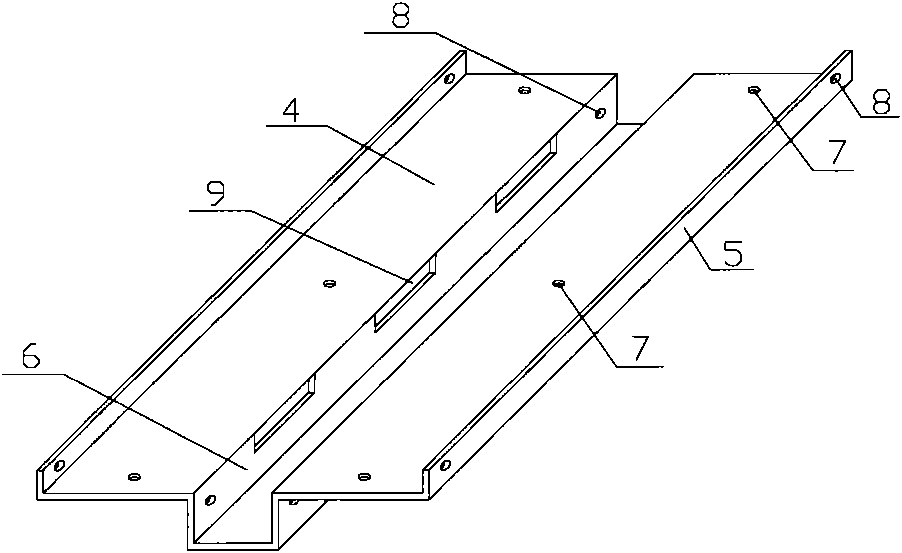

[0031] As shown in the accompanying drawings, the present invention is a ribbed prefabricated component formwork for construction. The ribbed prefabricated component formwork for construction is assembled from one or more than one module 1. The module 1 includes a base plate bottom form 4 and a base plate side formwork 5. And longitudinal rib sideform 6. The present invention is characterized in that: there are left and right through holes 9 on the longitudinal rib side mold 6 of the module 1 . When assembling ribbed prefabricated component templates for buildings, the modules 1 are docked and placed, and fasteners such as bolts 3 or bolts or threads are used to connect multiple modules through the connector 10, and the end block 2 is connected to the module 1. A filling block 11 is inserted into the through hole 9 on the longitudinal rib side form 6, and when pouring concrete, the concrete will not flow out from the hole 9 to form an integral ribbed prefabricated component te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com