Template engineering construction technology employing coiled material

A construction technology and roll material technology, which is applied in the field preparation of formwork/formwork components and building components, construction, etc., can solve the problems of low utilization rate, waste of resources, inflexibility of loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

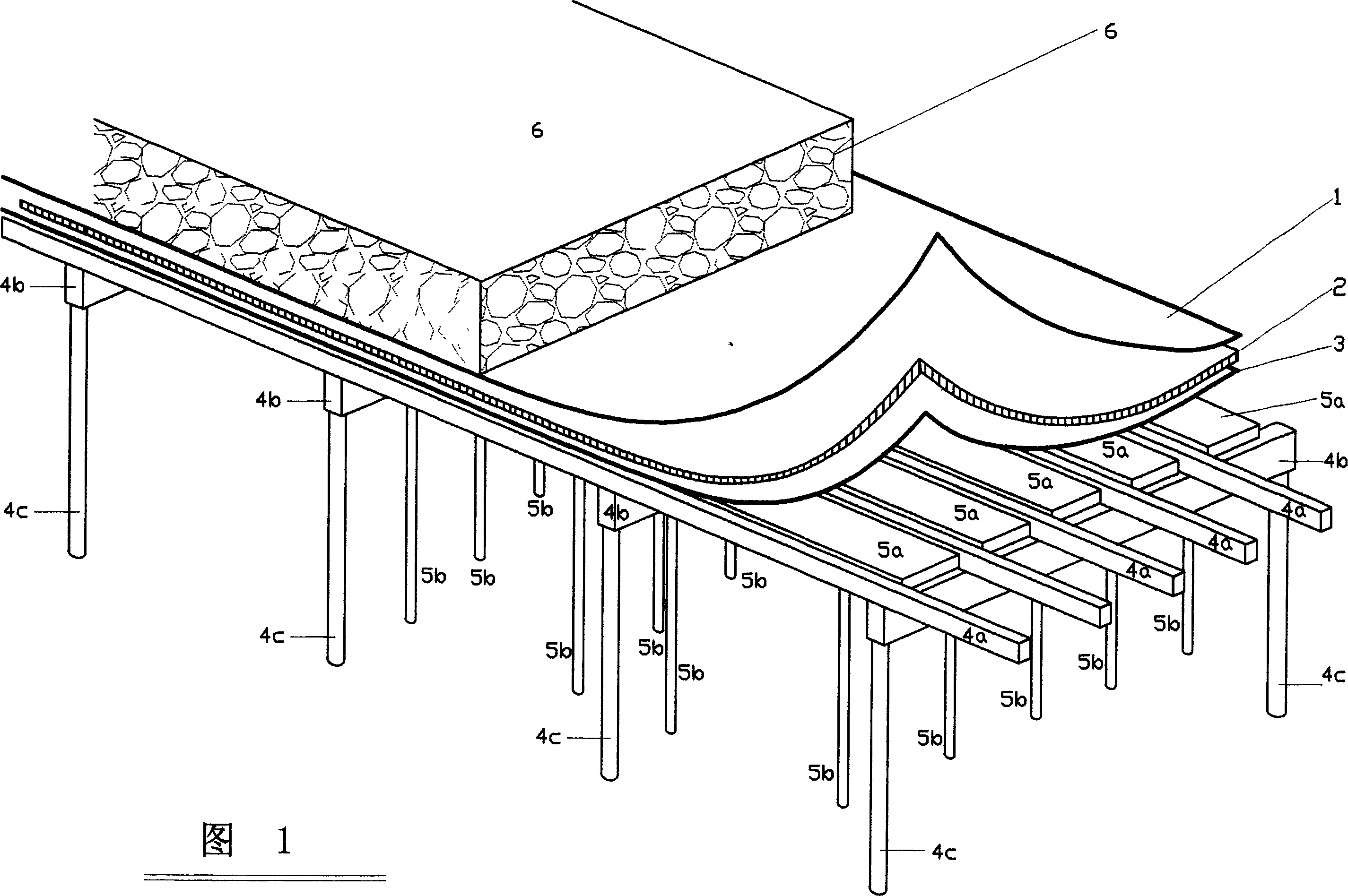

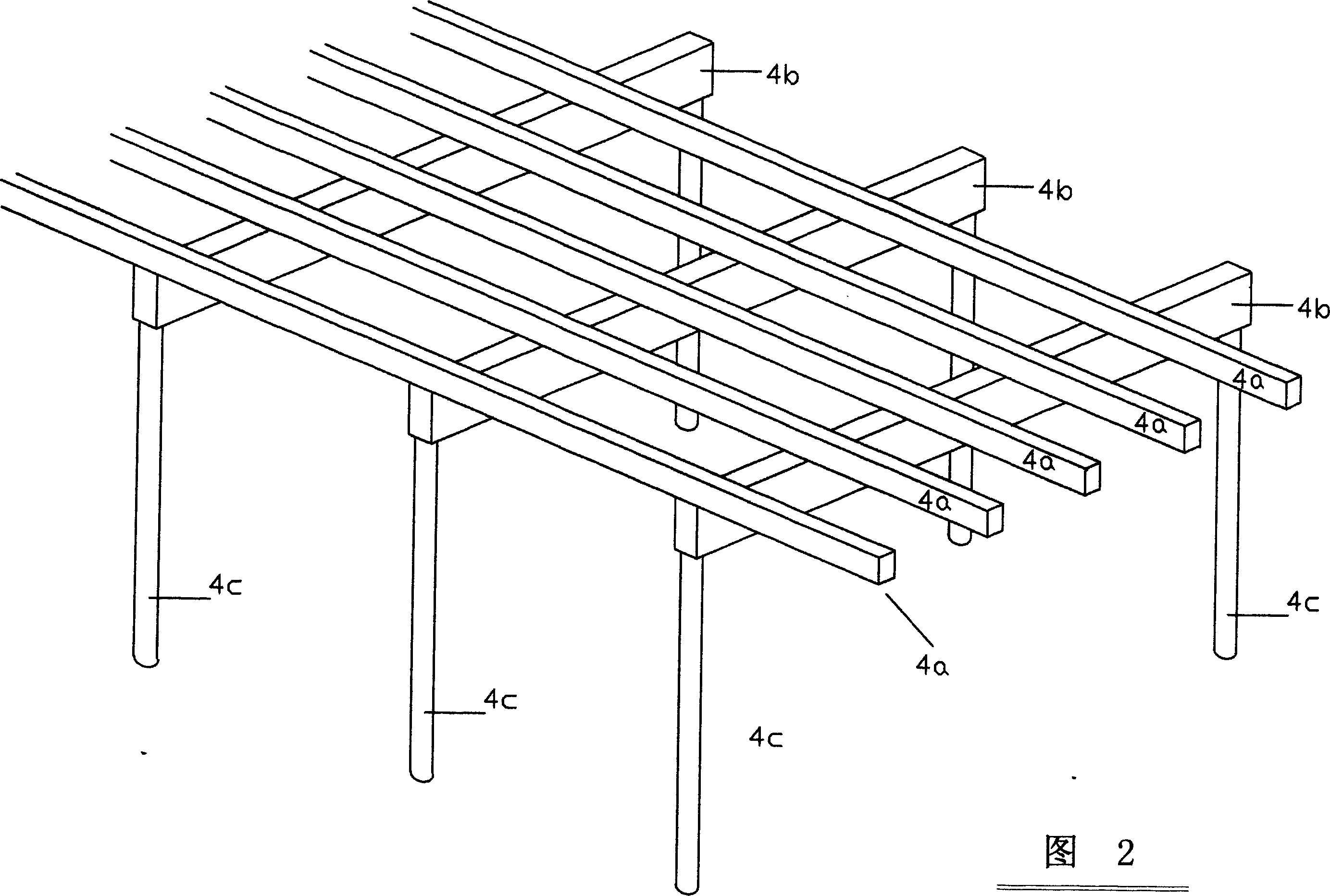

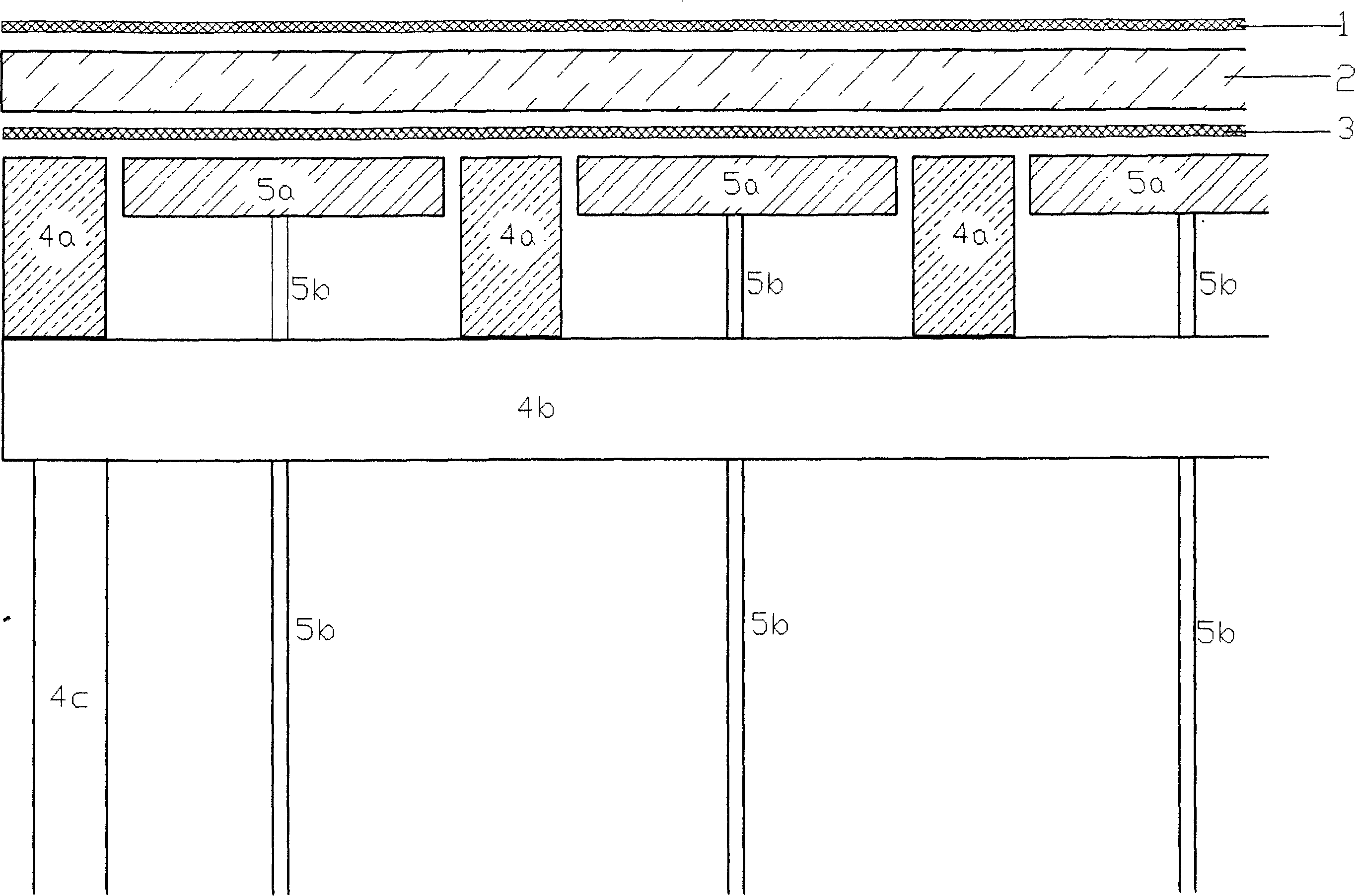

[0027] As shown in Figure 1, according to the size of the concrete member, set the keel of the fixed support system first, and the distance between the keel (4a) should be determined according to the rigidity of the surface coils (1) and (3), but the distance must be small Set, and there must be a keel aligned with the seam of the thick coiled material board (2); then set a temporary support system between the fixed support system keels (4a), and make the outer top surface of the temporary support system keel (5a) , on the plane formed by the keel (4a) of the fixed support system, the width of the keel (5a) is optimal to fill the gap formed by the keel (4a); finally lay the coil formwork.

[0028] In general, the surface size of cast-in-place concrete components is not an integral multiple of the size of a single coil formwork. When laying the formwork, it is necessary to stack at least two rows of the surface slabs in a certain linear direction ( Figure 5 ). Figure 5 -a is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com