Patents

Literature

46results about How to "Simple paving" patented technology

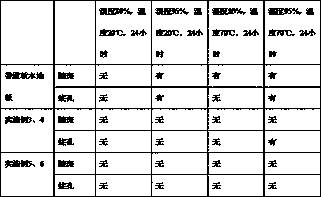

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prefabricated concrete road system and construction method

InactiveCN107022938AImprove structural strengthEasy to transportPaving reinforcementsIn situ pavingsElastomerRoad surface

The invention relates to the technical field of road construction, and provides a prefabricated concrete road system, which includes base layer curb stones; the curb stones are composed of horizontal stones and vertical edge stones; the area surrounded by the horizontal stones is paved with asphalt surface layer, Concrete pavement base and graded gravel layer; the concrete pavement base is spliced by several concrete slabs; the lower part of the gap between adjacent concrete slabs is filled with elastic materials, and the upper part is filled with expansion waterstop strips. The quality of the prefabricated concrete road system is easy to guarantee, easy to install, and easy to replace after being damaged. Also provided is a construction method, which includes filling the foundation layer; paving curb stones and rainwater wells; paving the graded crushed stone layer; paving the concrete pavement base; filling the joints of the concrete slabs with elastic materials; The curbstones and concrete slabs in this construction method are all processed in the factory, the site construction efficiency is high, and the later maintenance period is short.

Owner:CHINA 19TH METALLURGICAL CORP

Simulated marble slab and production method thereof

InactiveCN102700205AHard textureImprove wear resistanceNatural patternsSynthetic resin layered productsBuilding materialSubstrate surface

The invention relates to a marble slab, in particular to an artificial simulated marble slab and a production method of the artificial simulated marble slab. The invention aims to overcome defects of natural marble and provide the simulated marble slab which has low price, is light, is easy to pave, has no harm and pollution and can replace the natural marble. The simulated marble slab comprises a substrate layer. A priming paint layer, a marble pattern layer and a finish layer are sequentially arranged on the positive face of the substrate layer from bottom to top. The invention also aims to provide a production method of the simulated marble slab, which comprises the following steps of: selecting a substrate; tailoring the selected substrate to a required size; tenoning on tailored substrate; coating priming paint on the positive surface of the substrate; spraying natural marble patterns on the surface coated with the priming paint of the substrate; and coating finish on the surface sprayed with the natural marble patterns of the substrate. The simulated marble slab provided by the invention can be widely applied in multiple industries such as building material, advertisement, furniture, decoration and the like.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

Film pressure coating as well as film pressure floor and preparation method of film pressure floor

ActiveCN109852112AImprove wear resistanceReduce external frictionPolyurea/polyurethane coatingsFlooringPhotoinitiatorChemistry

The invention provides a film pressure coating. The coating comprises a radiation-curable adhesive primer layer, a radiation-curable wear-resistant primer layer and a radiation-curable film pressure finish coat layer in sequence from the bottom to the top; the radiation-curable adhesive primer layer is a conventional adhesive primer; the radiation-curable wear-resistant primer layer comprises thefollowing components, in parts by mass: 10-60 parts of acrylic resin A, 10-60 parts of an acrylate monomer A, 2-7 parts of a photoinitiator A, 5-40 parts of wear-resistant particles A and 3-10 parts of an additive A; and the radiation-curable film pressure finish coat layer comprises the following components, in parts by mass: 2-20 parts of acrylic acid-modified organosilicon resin having inorganic powder affinity, 2-20 parts of a two-functional polyurethane acrylate resin, 10-40 parts of multi-functionality polyurethane acrylate resin, 5-50 parts of an acrylate monomer B, 2-7 parts of a photoinitiator B, 5-40 parts of wear-resistant particles B, and 3-10 parts of an additive B. The invention also provides a film pressure floor containing the above film pressure coating and a preparation method of the film pressure floor. The film pressure coating provided by the invention has the characteristics of excellent wear resistance, scratch resistance, long-lasting self cleaning and high hardness; and the prepared film pressure floor has the characteristics of a comfortable foot feeling, slitting slotting, greenness, environmental protection, energy saving and high efficiency.

Owner:HUNAN BANFERT NEW MATERIALS TECH

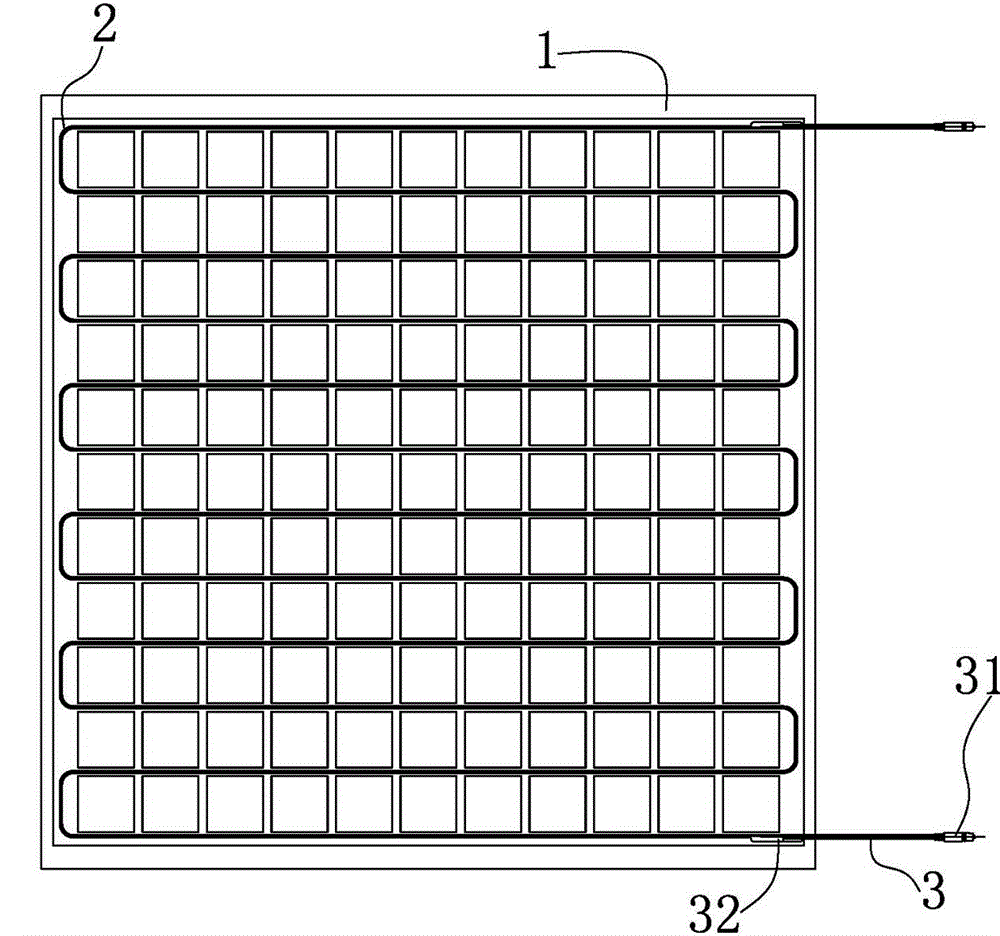

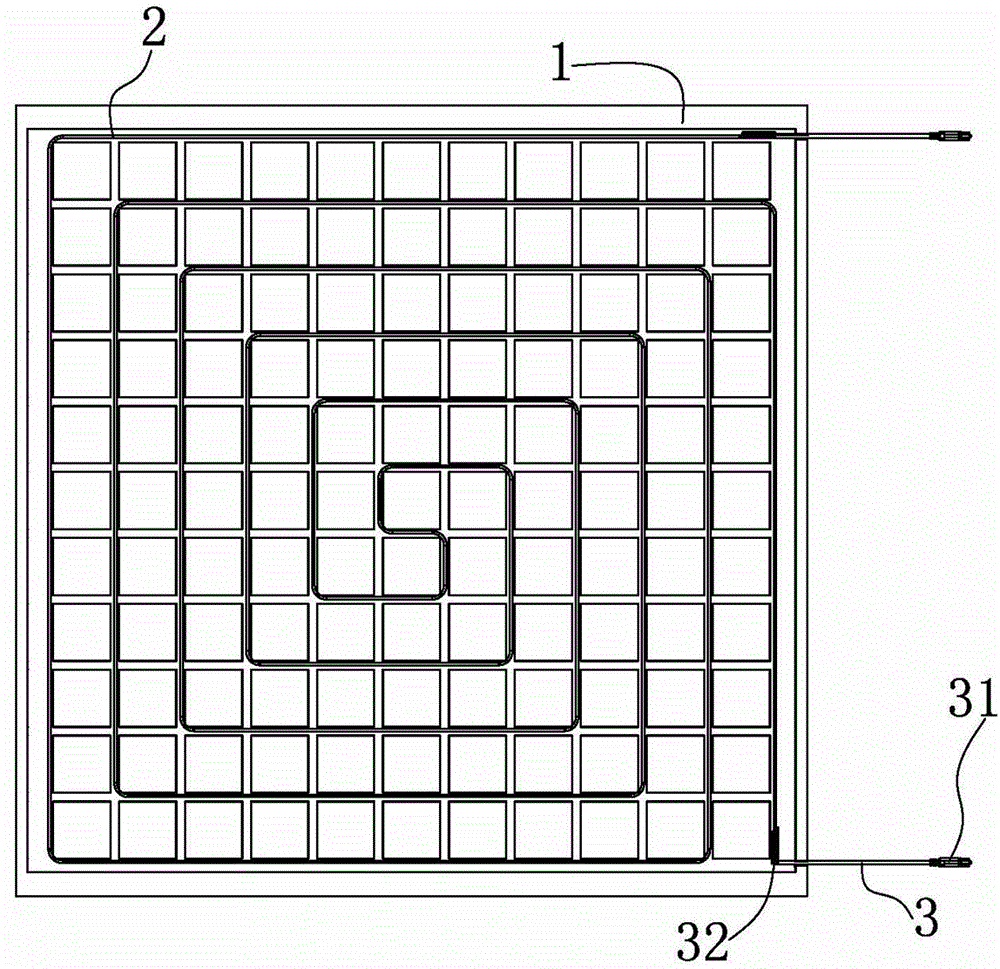

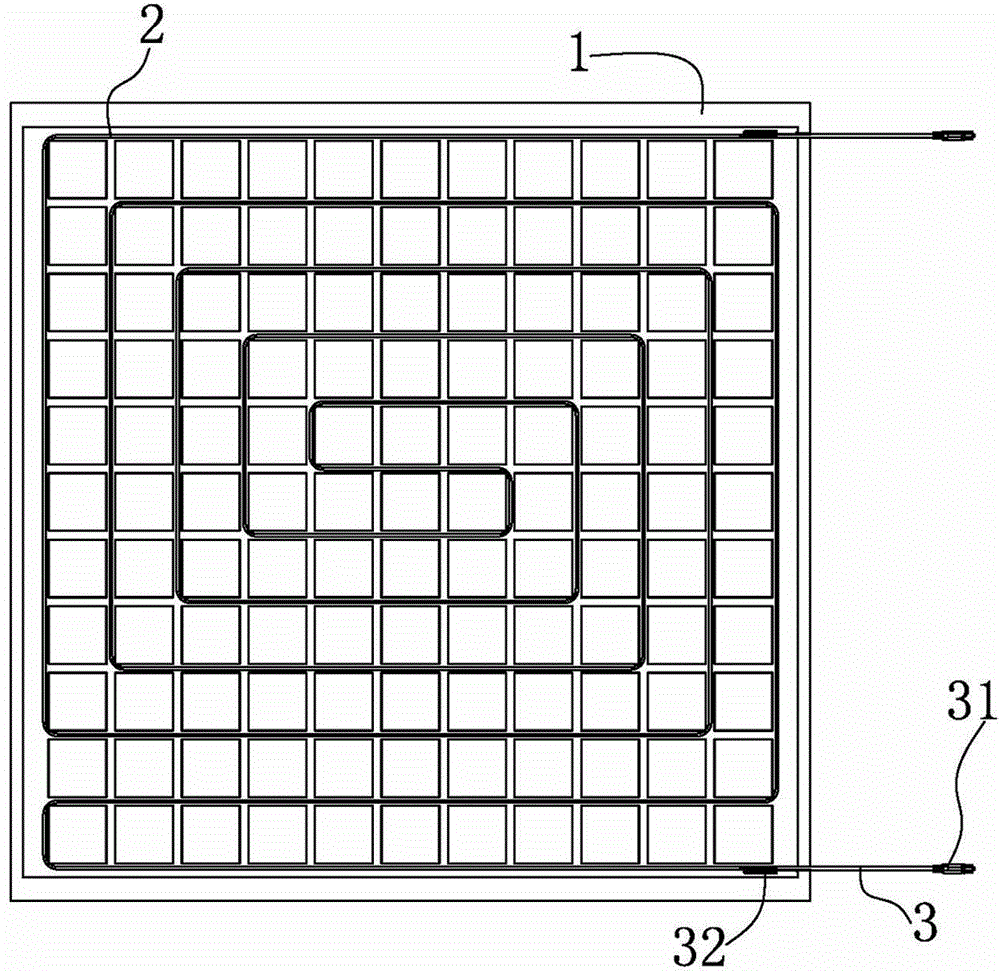

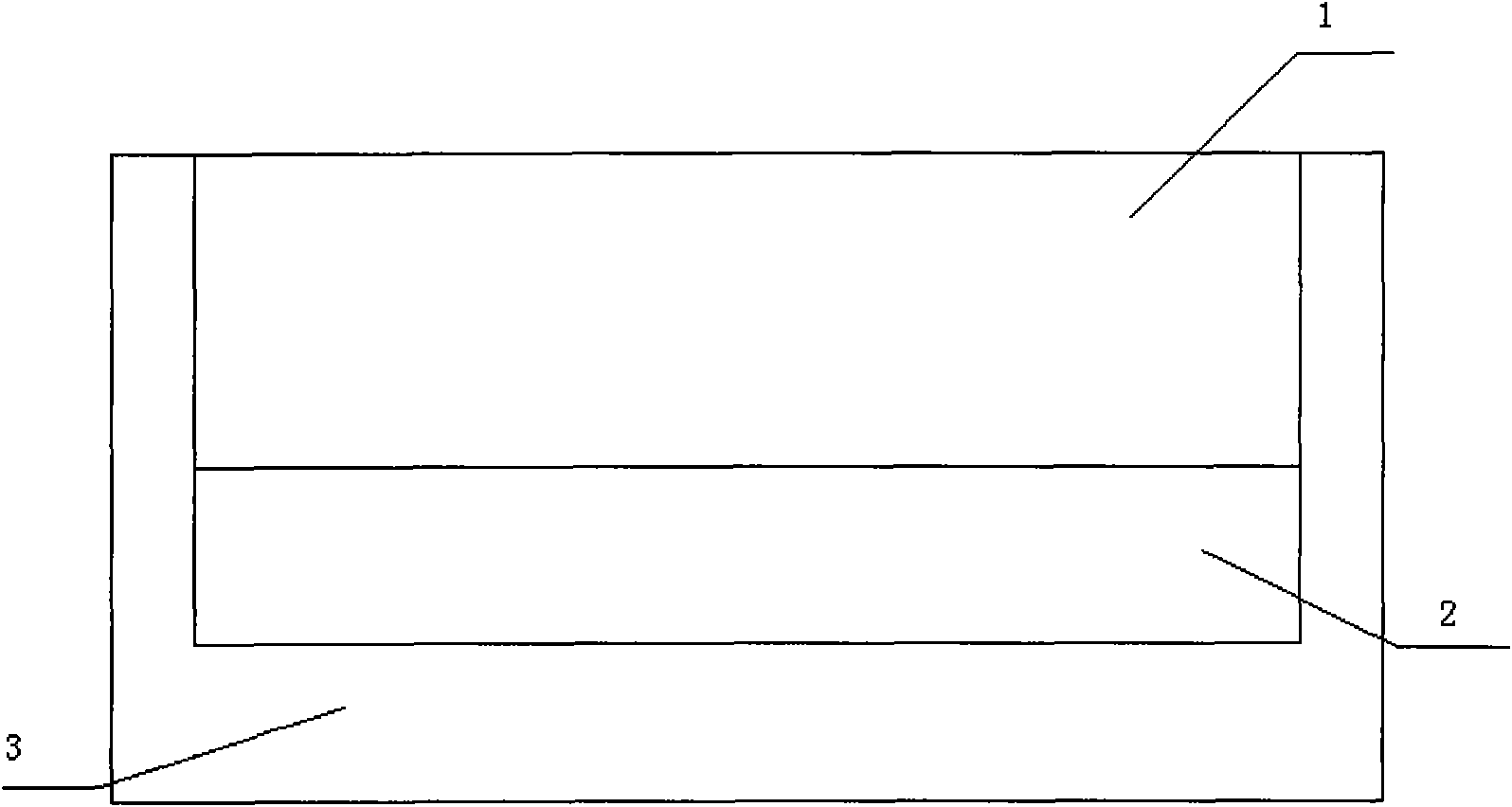

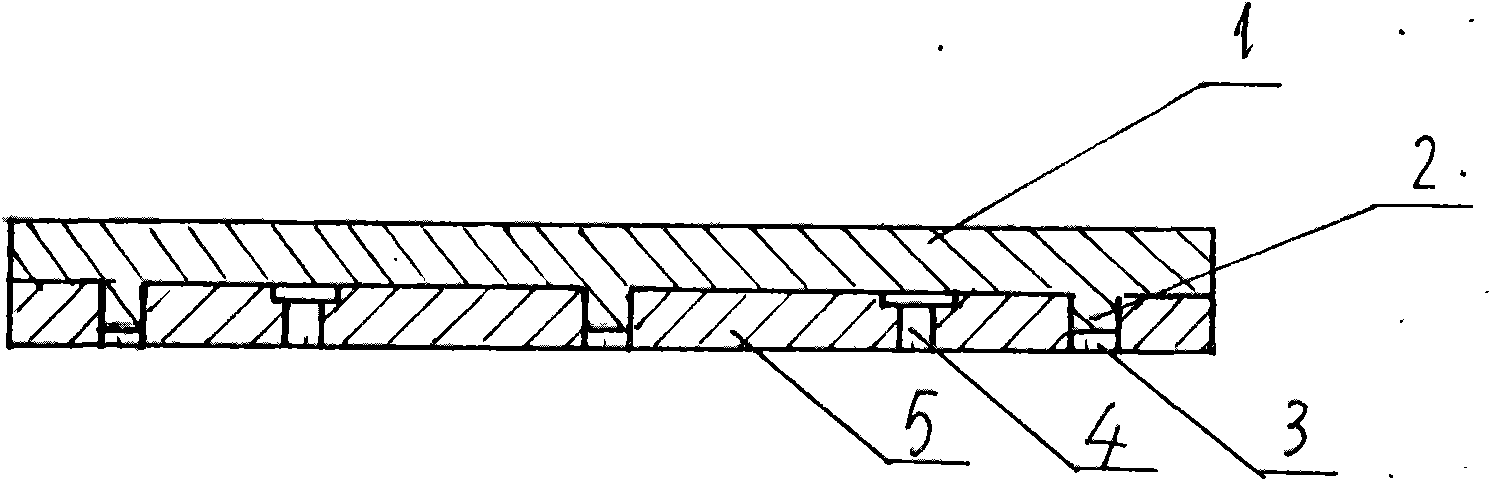

Heating tile

InactiveCN104595963ASimple structureLow costLighting and heating apparatusElectric heating systemAdhesiveHotline

The invention provides a heating tile, and relates to the field of heating floors. The heating tile comprises a tile body, a heating wire and a power line. One face of the tile body is provided with a heating wire groove. A conductive wire is arranged on the central axis of the heating wire. An insulating sleeve wraps the conductive wire. The heating wire is embedded in the heating wire groove and fixed through adhesives. The two ends of the power line are provided with a three-proofing interface and a wiring terminal respectively. The two ends of the heating wire are both connected with the end, provided with the wiring terminal, of the power line. Insulating layers wrap the joint of the heating wire and the wiring terminal, the wiring terminal and the joint of the power line and the wiring terminal. The power line extends out of the tile body. The heating tile is simple in structure, small in thickness, rapid in heating, uniform in heat conduction, low in energy consumption, long in service life and convenient, easy and rapid to lay.

Owner:佛山市暖万家热能科技有限公司

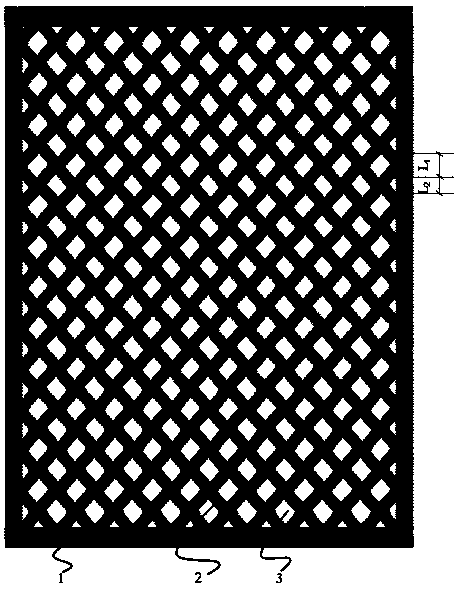

Convenient brick grass and manufacture method thereof

The invention discloses a convenient brick grass and a manufacture method thereof. The convenient brick grass has three parts from top to bottom, which are respectively called as an upper layer, a middle layer and a base, wherein the upper layer is mixed by an organic fertilizer, clays and seeds; the middle layer is a mixed layer of a water-retaining agent and clays; and the base is mixed by a deburring medicament, water and soil. Components of the three parts are mixed according to a certain proportion, respectively compressed and placed together to carry out total compression to manufacturethe brick grass similar to the property of floor tiles, thereby having low requirement on the field and convenient pavement and greatly reducing the cost.

Owner:孙惊雷

Decorative section

InactiveCN101922223ANo harmSolve employment problemsCovering/liningsSolid waste managementHeat stabilityThermal expansion

The invention relates to a decorative section which is prepared by the following raw materials by weight percent: 39%-71% of heavy calcium carbonate or mine tailing sand, 25%-50% of waste plastics and 4%-6% of chemical additives, wherein the chemical additives comprise the following components: heat stabilizer, stearic acid, chlorinated polyethylene, titanium dioxide, paraffin, antioxidant and anti-ultraviolet agent. The decorative section has the benefits of good heat conduction performance, good heat stability, good environmental protection performance, no thermal expansion and contraction, erosion resistance, antibacterial property, mothproof property, resistance to water soaking, fire resistance, flame retardancy, anti-skid property, no burst, good anti-deformation property, good electrostatic prevention, good elasticity, good product quality, greenness, environmental protection, capability of changing waste into treasure, and low cost.

Owner:安徽晶冠新材料科技有限公司

Elastic plastic floor and manufacturing method thereof

InactiveCN103174280ASimple processEasy to installLamination ancillary operationsLayered product treatmentSurface layerWear resistant

The invention discloses an elastic plastic floor. The elastic floor is compounded by a wear resistant surface layer and a sheet material layer. The wear resistant surface layer is fit in a heat mode by a wear resistant layer and a lathe work layer. The sheet material layer is a polyvinyl chloride (PVC) plastic or wood sheet material. A manufacturing method of the elastic plastic floor comprises the following steps: step A, sheet material sizing, the sheet material is placed in a high temperature oven for sizing; step B, cooling and sizing are conducted on the sheet material treated by the step A; step C, glue and a glue roller are heated, the sheet material treated by the step B is coated with glue and attaches to the wear resistant surface layer and is finally fit in a rolling and pressing mode. The wear resistant layer and the lathe work layer of the floor are heated into a surface layer through a rolling and pressing technology, and then directly attaches to the sheet material to be processed into floor. Products are divided into three layers, the elastic plastic floor has the advantages of being simple and convenient in working procedures, water-proof and fire-proof, free of formaldehyde, simple in laying and installing, good in sound insulation effect, clear in embossment effect, high in production efficiency, low in production energy consumption and the like.

Owner:XIANJU COUNTY DEYI DECORATION MATERIAL

Combined adhesive-free wall body surface decorative brick

A combined adhesive-free wall body surface decorative brick belongs to a building wall body decorative product. A base brick is provided with a mounting and connecting fixed hole and a countersunk head screw hole; a mounting and connecting fixed column matched with the mounting and connecting fixed hole is arranged on the inner side surface of a surface brick and is inserted and configured in the mounting and connecting fixed hole; and the surface brick is fixedly arranged on the outer surface of the base brick to form a whole. The brick adopts a surface brick and base brick combined structure, is free from using any adhesive during pavement on the wall surface and has the characteristics of novel and reasonable design, easy pavement, favorable pavement quality, easy operation, low labor intensity, high operation efficiency and long service life.

Owner:姚福才

Large block wooden floor

The present invention relates to a floor board, in particular, it relates to a large block wood floor board. The whole block large floor board is formed from several small boards, the periphery of small board is equipped with tenon and mortise, on the surface of small board a hole is set. These small boards can be connected togther by adopting tenon-mortise and connector and formed into a whole body so as to form the invented large block floor board.

Owner:邢一

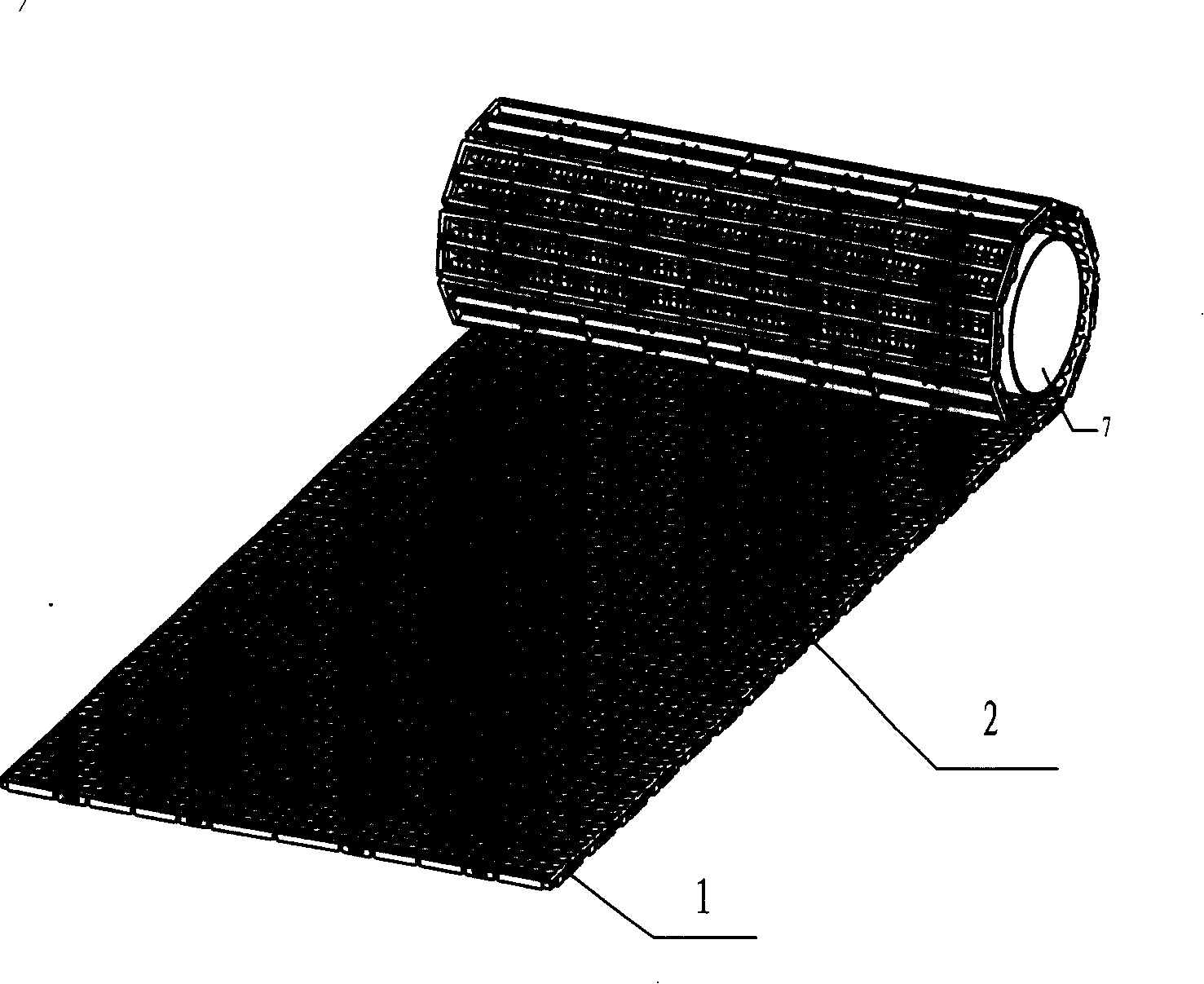

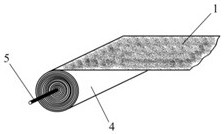

Drum type grassplot armour plate

InactiveCN101180938ANot easy to fall off naturallyNot easy to fall offPlant protective coveringsBand shapeEngineering

The invention provides a reel-type lawn protection board with air pores, which is simple in assembly and disassembly and convenient in maintenance and replacement. The protection board is formed by stripped lawn protection units which are all vertically connected with ribbon-shaped lawn protection blocks in sequence; the lawn protection blocks can be vertically reeled and the neighboring blocks are horizontally connected with each other.

Owner:丰岳

Two-layer floor based on beam bridge structure

The invention provides a two-layer floor based on a beam bridge structure. The two-layer floor is characterized by comprising core boards, edgings, a veneer and reinforcing strips, wherein the core boards, the edgings and the reinforcing strips constitute a floor base material, the edgings are connected with the two sides in the width direction of the core boards in a splicing mode, and one or more reinforcing strips are added to the middle of the two core boards. A processing technology of the two-layer floor includes the first step of splicing the core boards, the second step of determining the thickness of the core boards, the third step of assembling the floor base material, the fourth step of determining the thickness of the floor base material, the fifth step of covering the floor base material with the veneer, and the sixth step of forming the floor. The two-layer floor has the advantages that firstly, the two-layer floor is easy to lay, low in cost and small in residual stress; and secondly, due to the beam bridge structure, air on the back of the laid floor can circulate, the deformation probability of the floor is reduced, the quality level of the two-layer floor can be remarkably improved, and the life cycle of the two-layer floor can be remarkably prolonged.

Owner:GUANGDONG YIHUA TIMBER IND

Municipal road passive safety device and mounting method thereof

ActiveCN110055850ARealize security protectionReduce car damageTemporary pavingsRoadway safety arrangementsRebarAutomotive engineering

The invention discloses a municipal road passive safety device and a mounting method thereof. The municipal road passive safety device comprises a concrete layer poured on the ground, a plurality of layers of vertically and parallelly arranged reinforcement cages are poured in the concrete layer, after the concrete layer is poured, a slope surface with the gradient being 3-6 degrees is formed, during vehicle buffer, a vehicle travels from the low end of the slope surface to a high position, and the transverse length of the poured concrete layer is 200-300 m. According to the municipal road passive safety device, the vehicle can be decelerated.

Owner:嵊州市万睿科技有限公司

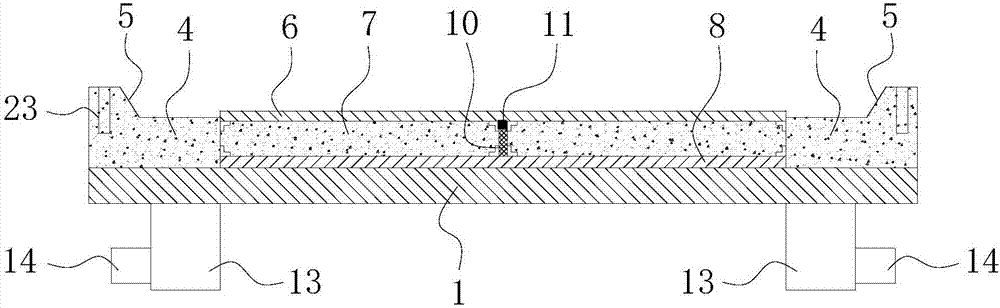

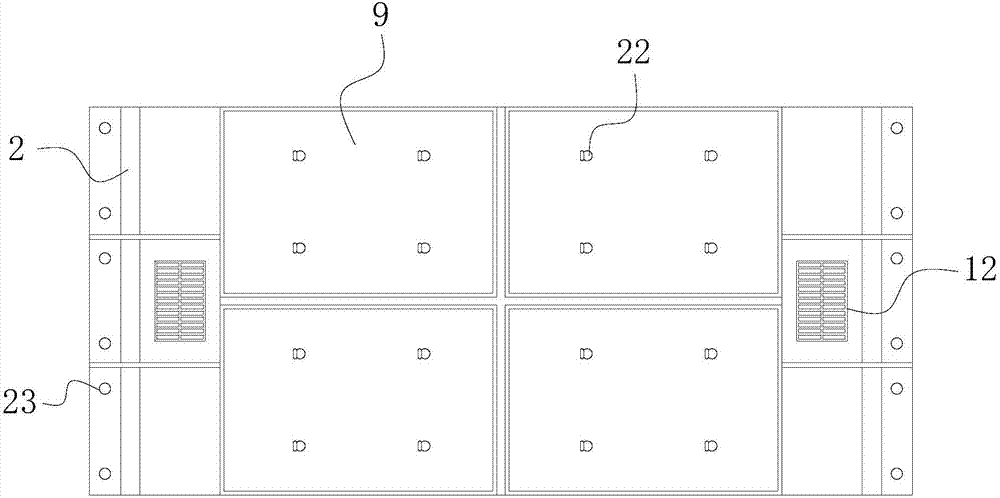

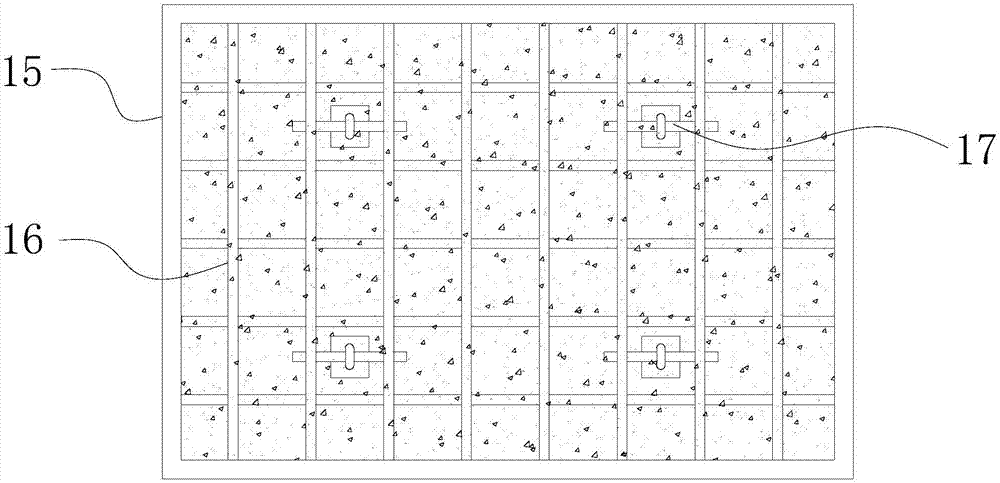

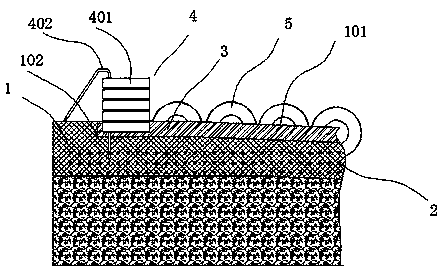

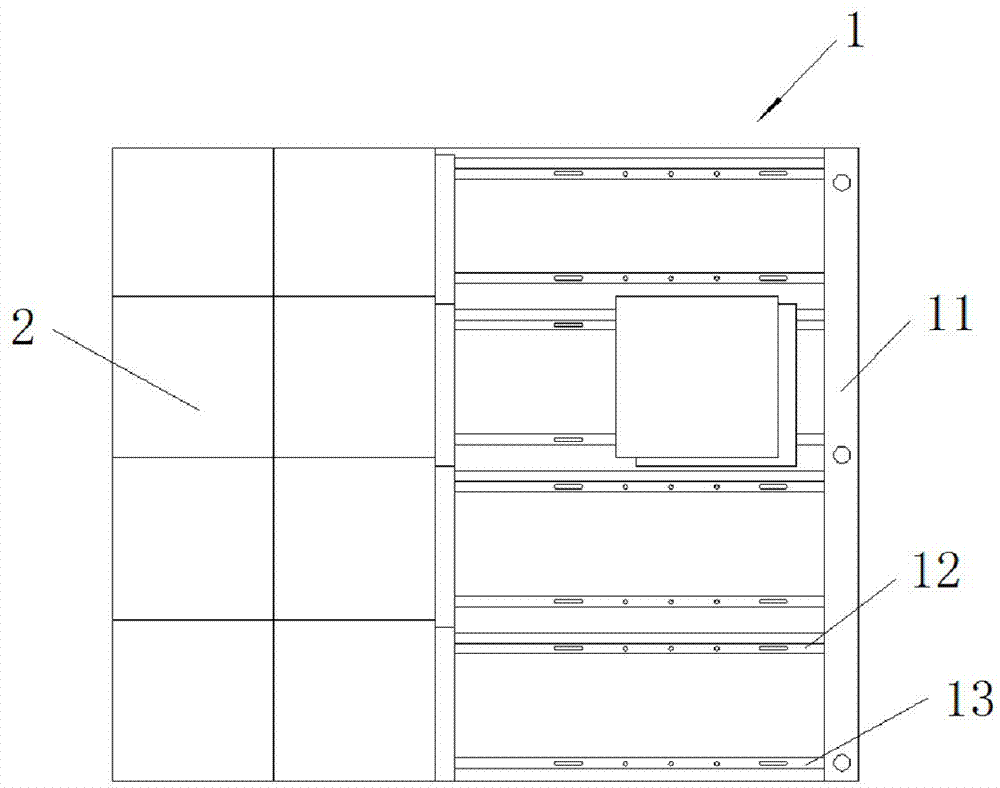

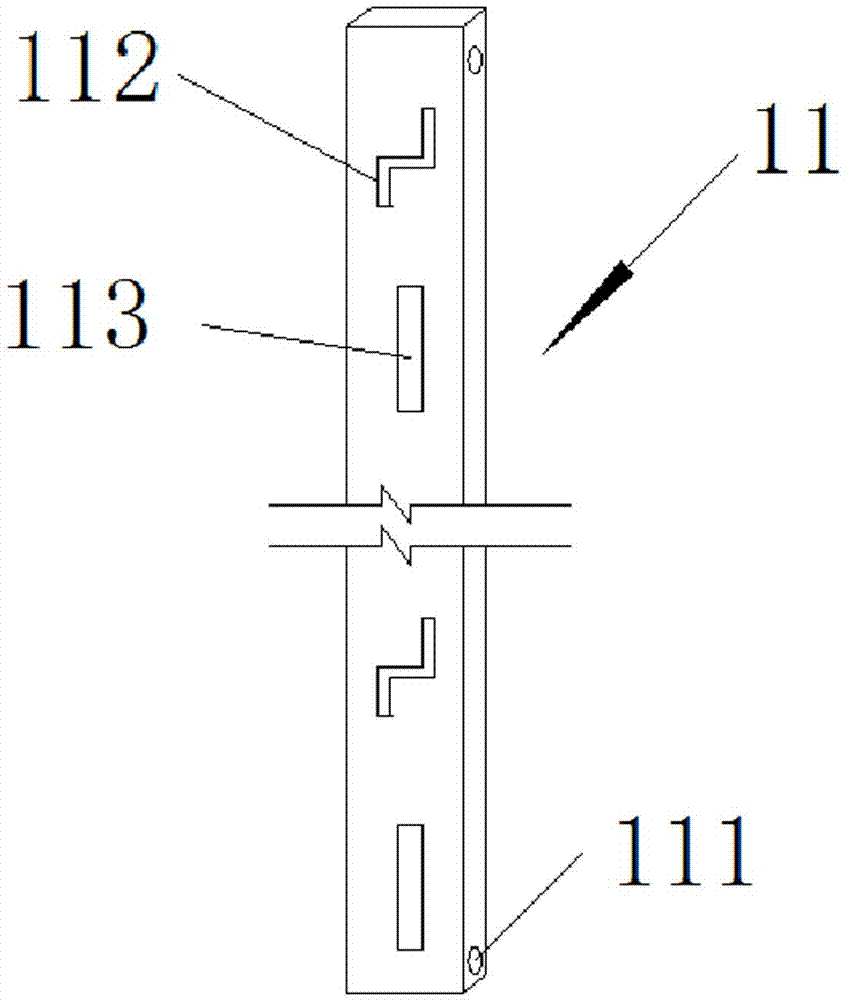

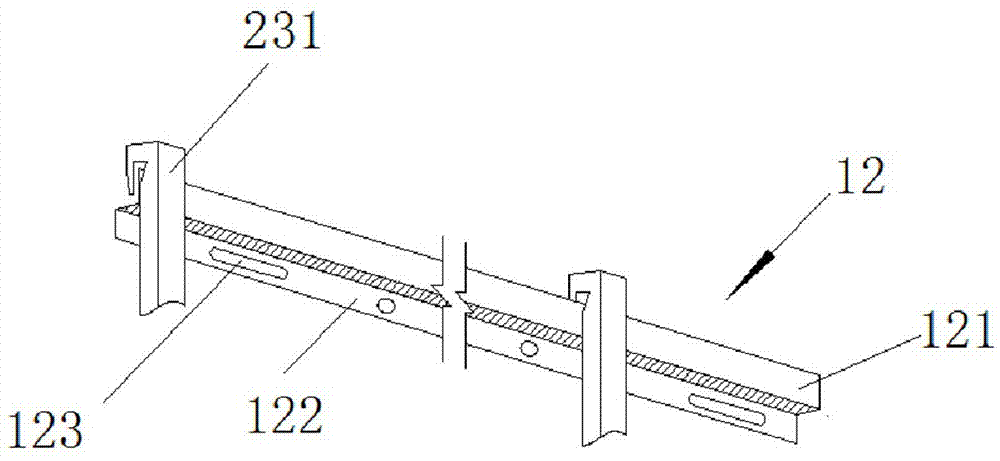

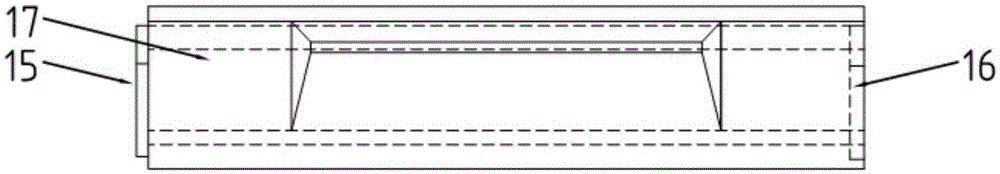

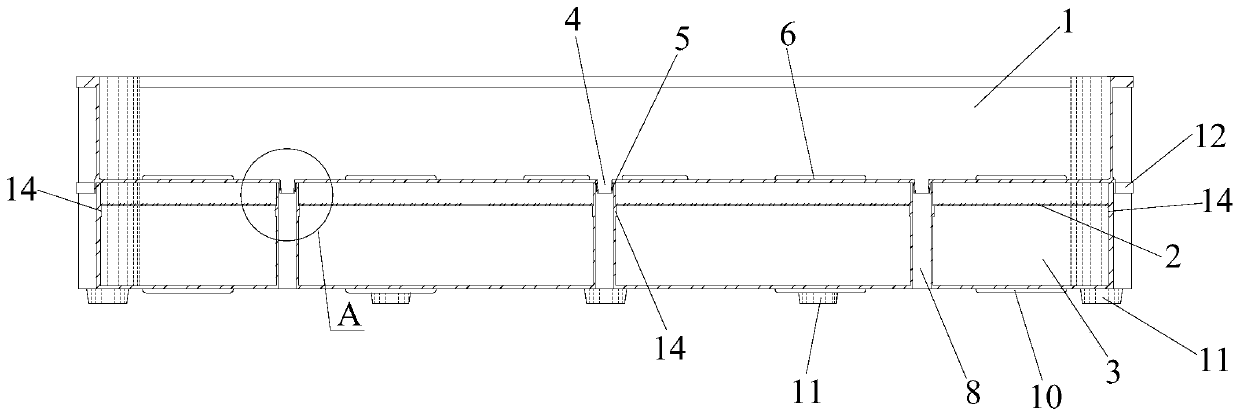

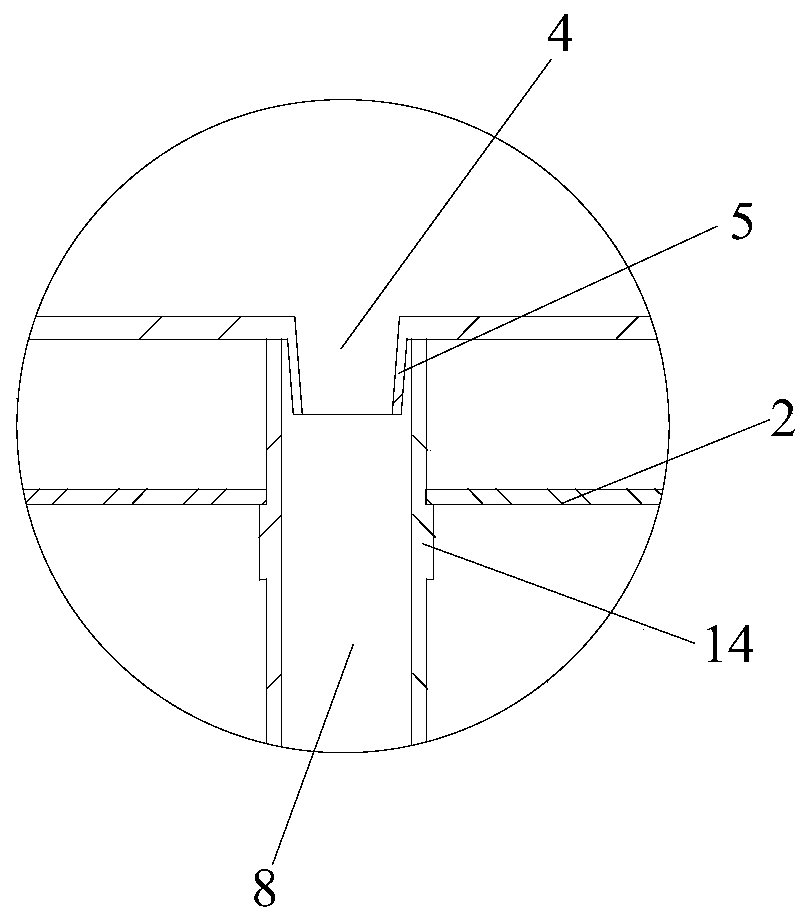

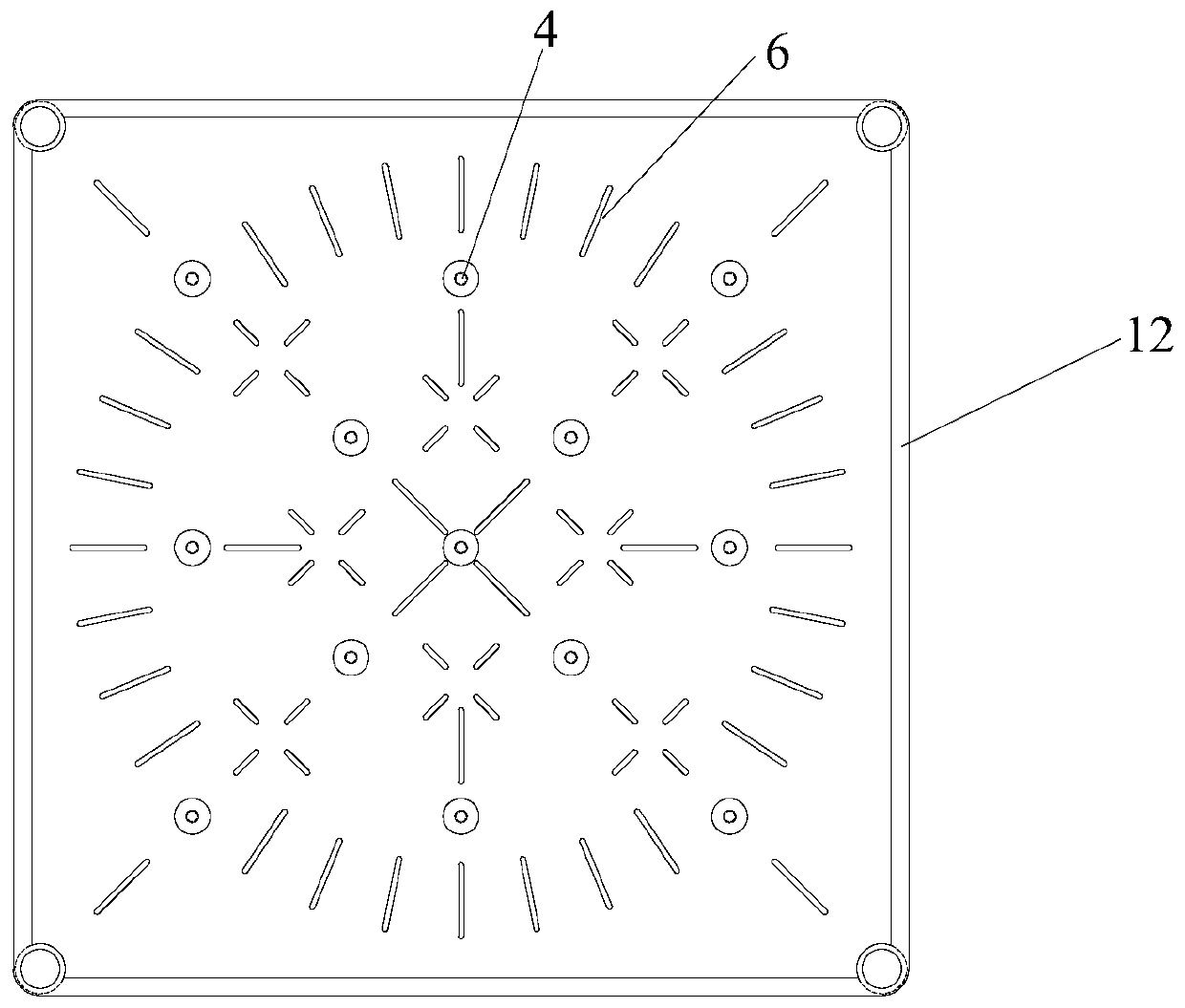

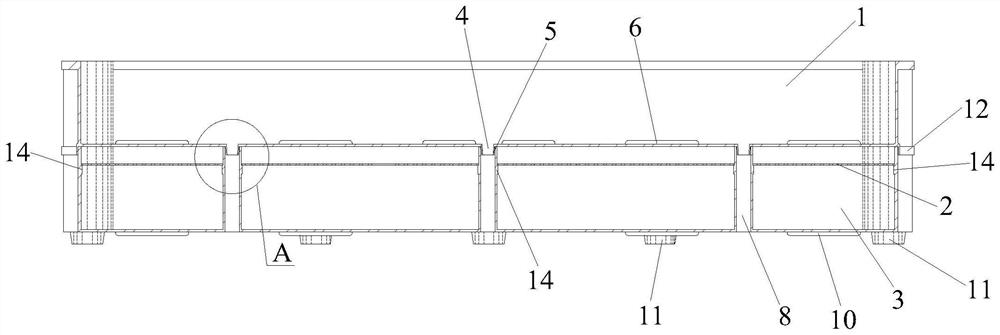

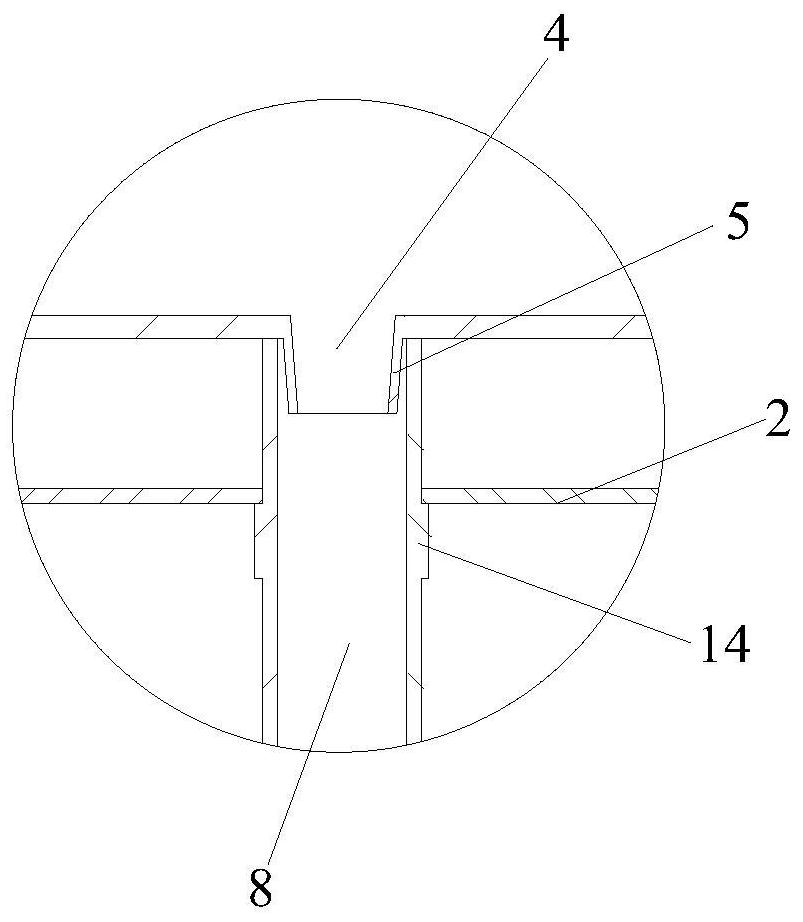

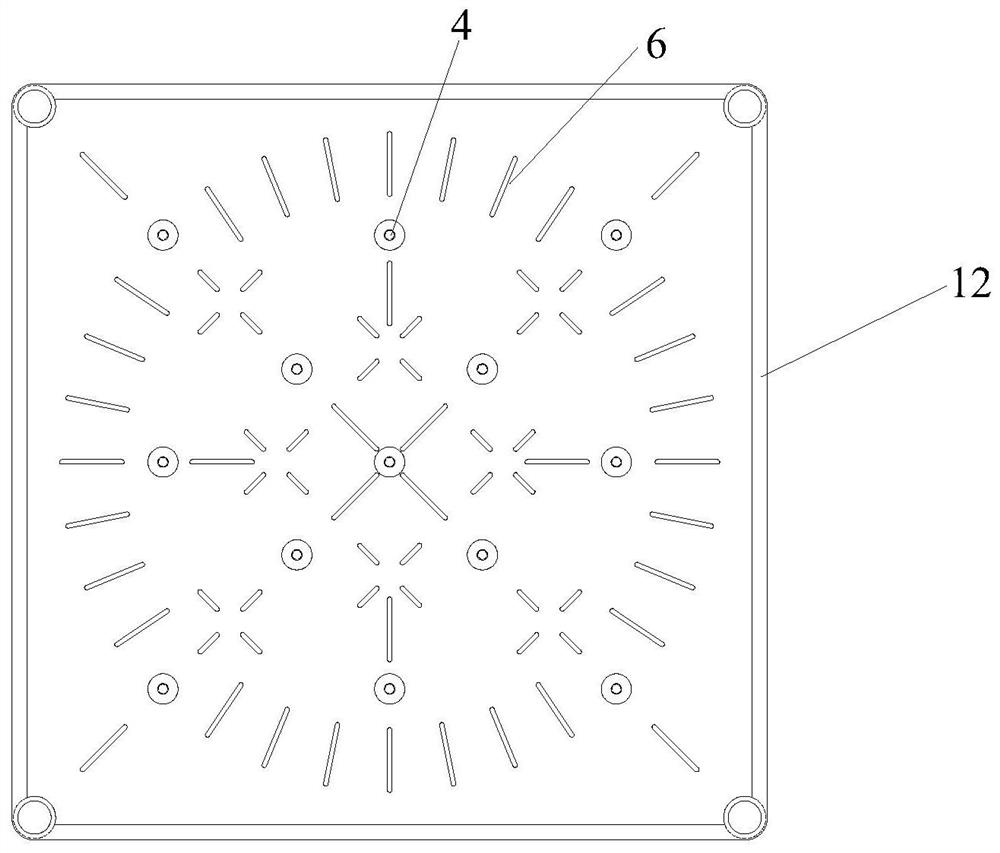

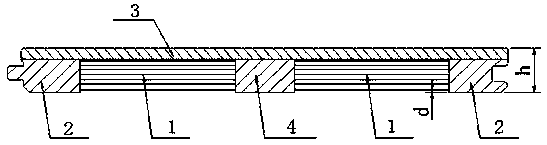

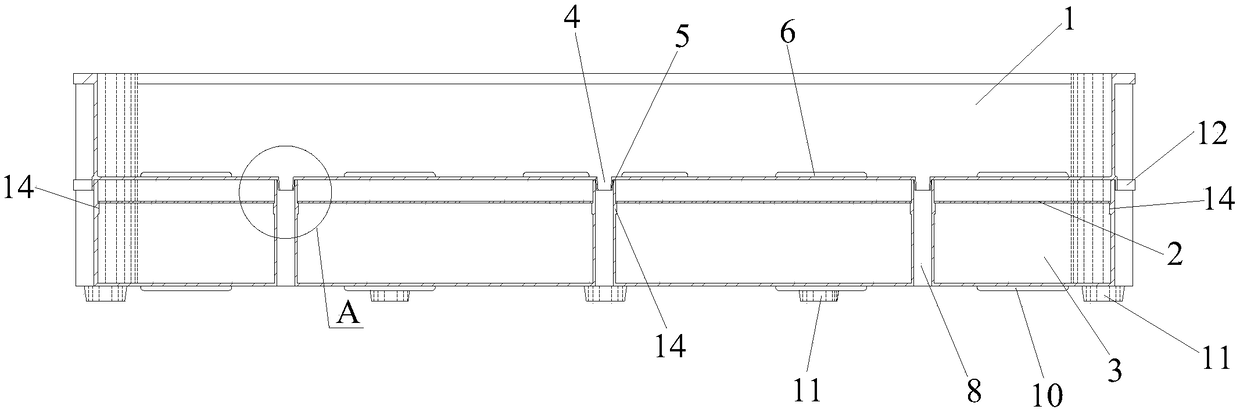

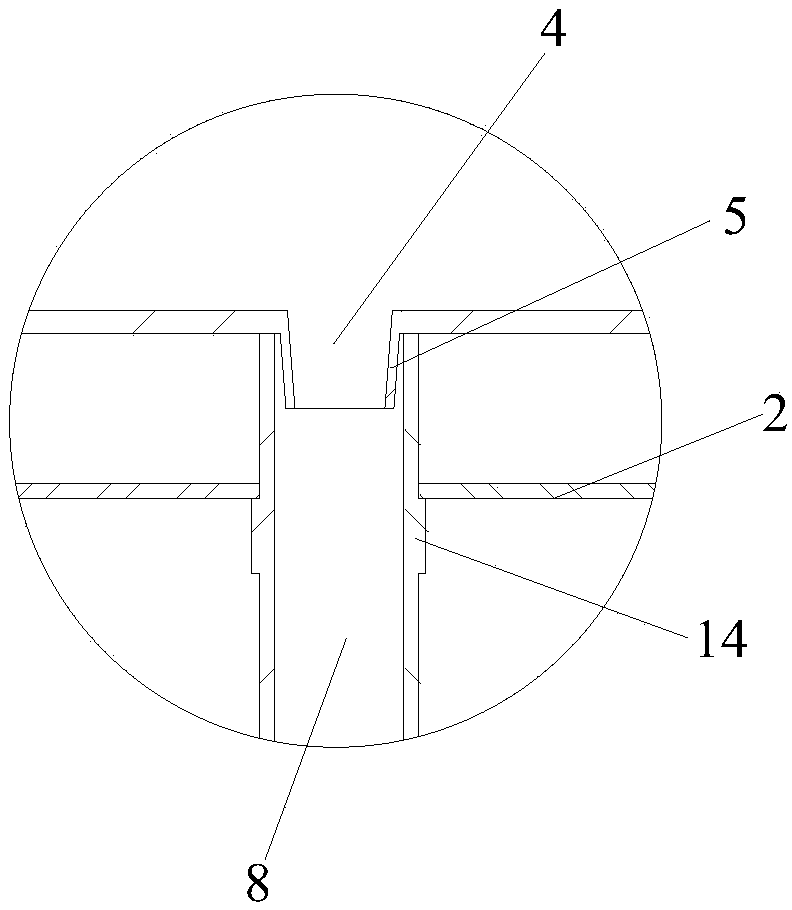

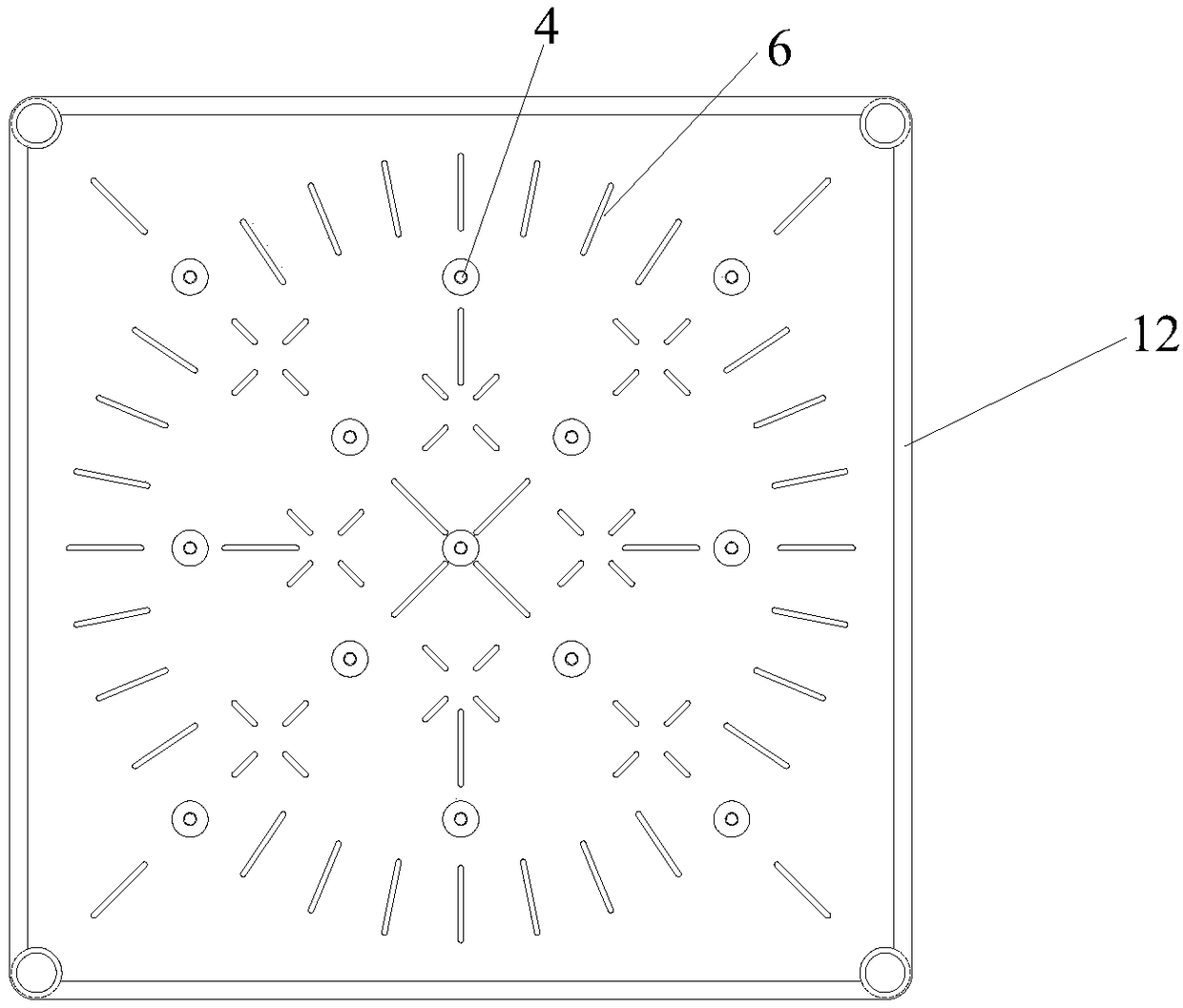

Precast concrete road system and construction method

ActiveCN108004866AEasy to replaceImprove the level of civilized constructionSingle unit pavingsPaving gutters/kerbsRoad surfaceBasic block

The invention discloses a precast concrete road system and a construction method and relates to the technical field of road construction. The road system comprises a basic layer, a curb layer, a filling layer and a pavement layer; the basic layer is paved with concrete precast basic blocks with reversed-T-shaped longitudinal sections; the curb layer is paved with rectangular solid concrete precastcurb blocks; the filling layer is paved with precast filling blocks of a box-shaped structure; and the pavement layer is laid at the top of a structure composed of a vertical layer of the basic layer, the curb layer and the filling layer, and the pavement layer is paved with concrete precast pavement board blocks. By the adoption of the system, the basic layer is paved with the multiple basic blocks in an attached and crossed mode, the curb layer is paved with the multiple curb blocks in an attached and crossed mode, the filling layer is paved with the multiple filling blocks in an attached and crossed mode, the pavement layer is paved with the multiple pavement board blocks in an attached and crossed mode, the system is convenient to transport, easy to lay, short in site construction time, high in construction efficiency, capable of being reused, easy to replace after being damaged and small in construction waste.

Owner:马晓鹤

Marble composite board background wall and process for paving thereof

PendingCN106854927ANot easy to damageImprove flatnessCovering/liningsStructural engineeringComposite slab

The invention relates to a marble composite board background wall and a process for paving thereof. The marble composite board background wall comprises a connecting assembly fixedly connected with an outer wall and a marble composite board connected to the connecting assembly. The connecting assembly comprises two longitudinal parts vertically arranged at intervals, a first transverse part and a second transverse part, wherein the first transverse part and the second transverse part are arranged at intervals, and the two ends of the first transverse part and the second transverse part are inserted in the longitudinal parts. The first transverse part is provided with a first hook part and the second transverse part has magnetism. The marble composite board comprises a panel, a middle plate and a base plate which are sequentially laminated. The panel is aligned with the panel. The middle plate, the panel and the base plate are staggered. The upper portion of the base plate is provided with a hook hung on the first transverse part, and the lower portion of the base plate is provided with a magnetic part adsorbed to the second transverse part. A background wall paved by using the marble composite board background wall through the paving process not only is simple and practical in paving process, can be operated by an ordinary technicians and is high in flatness, but also enables the marble composite board not to be damaged easily, and is environmentally friendly and practical and saves time and labor.

Owner:林文华

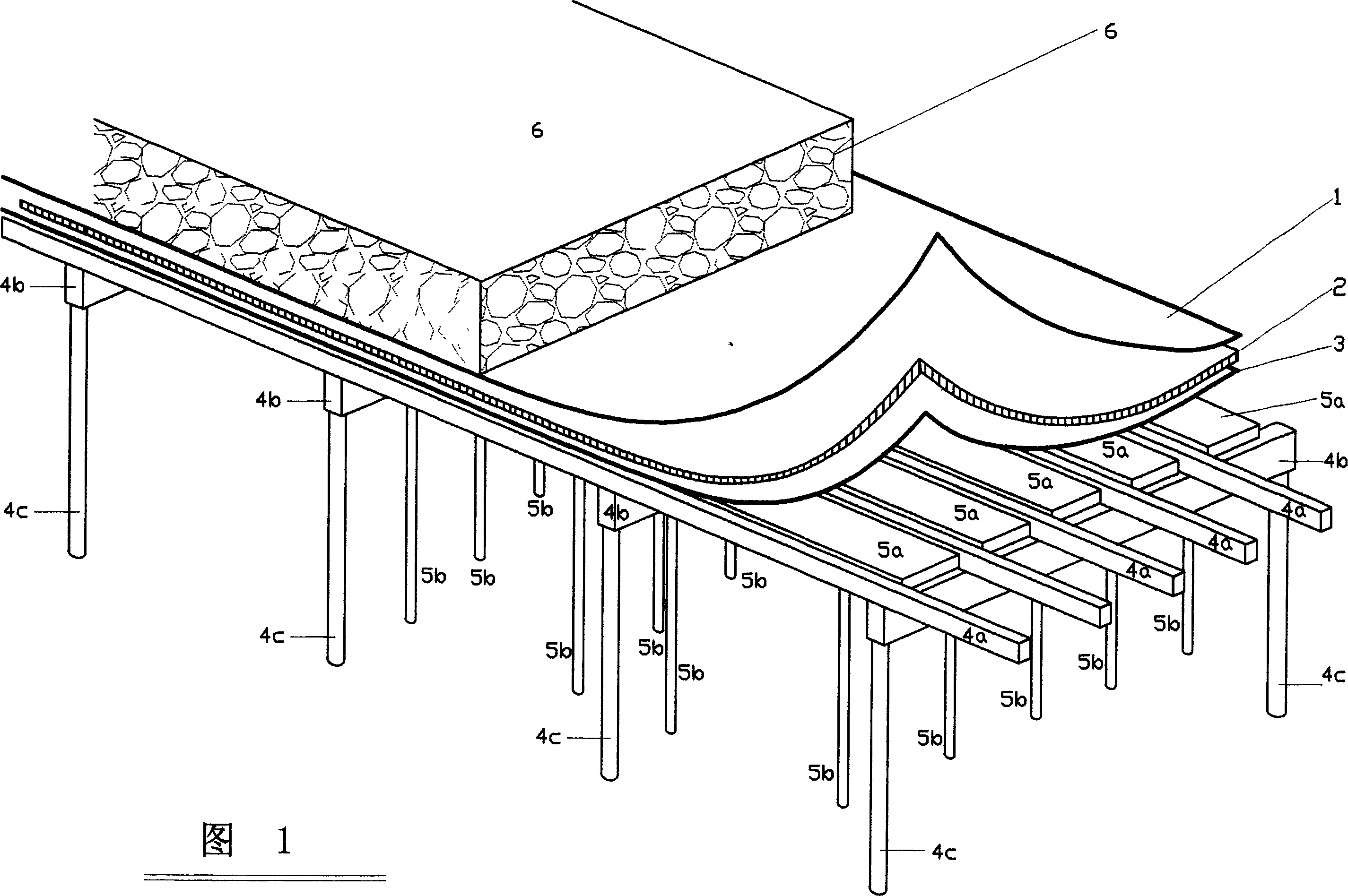

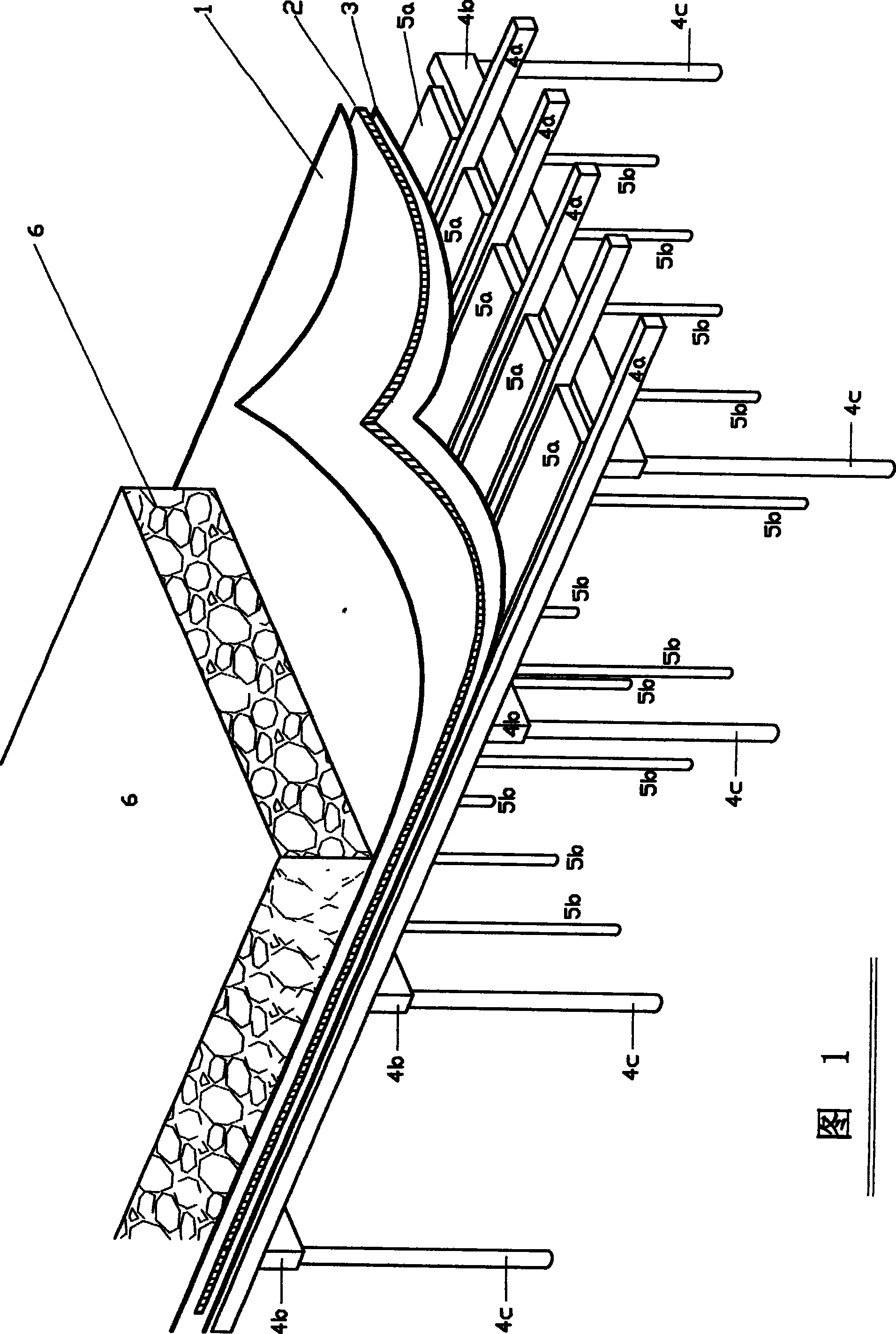

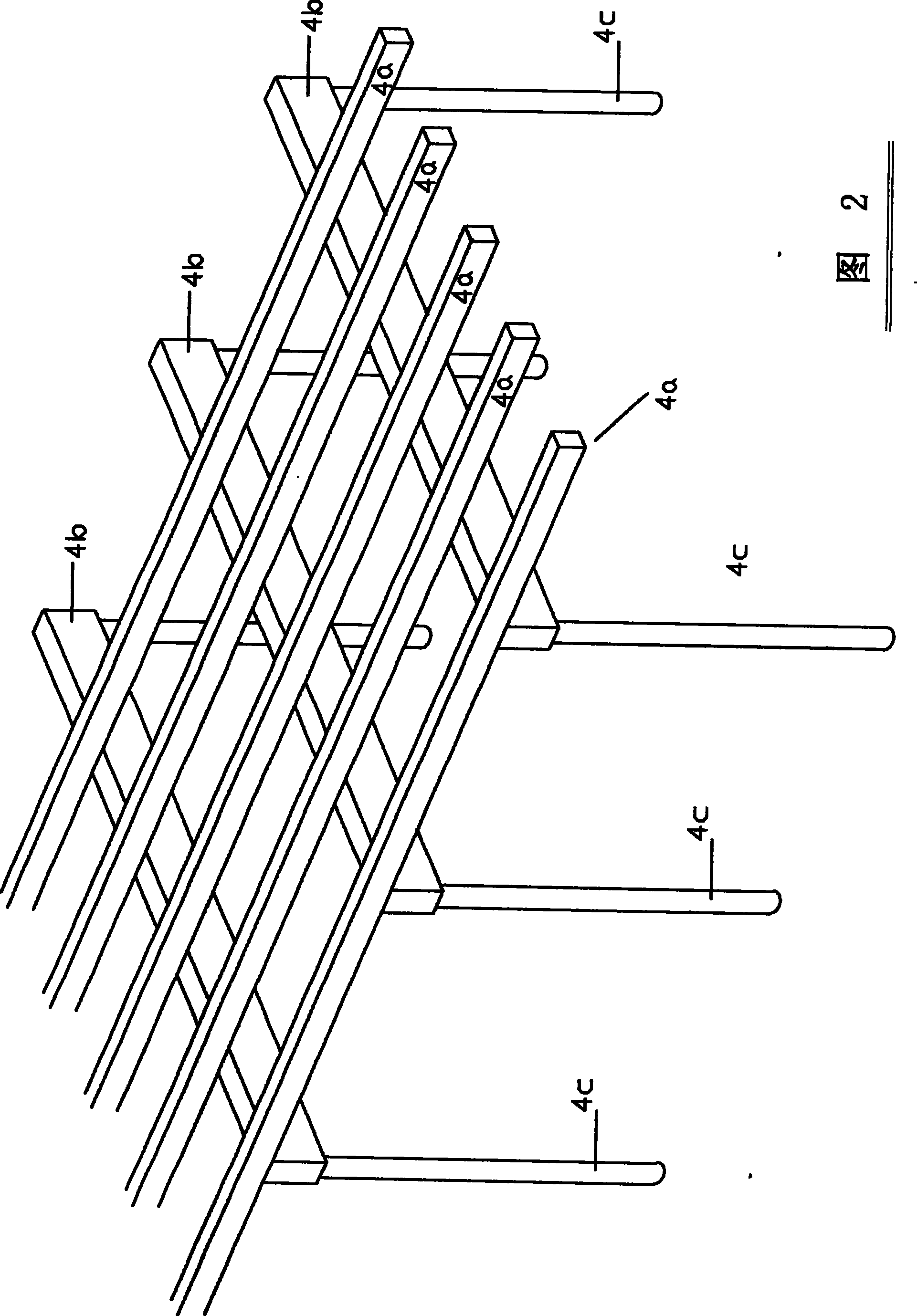

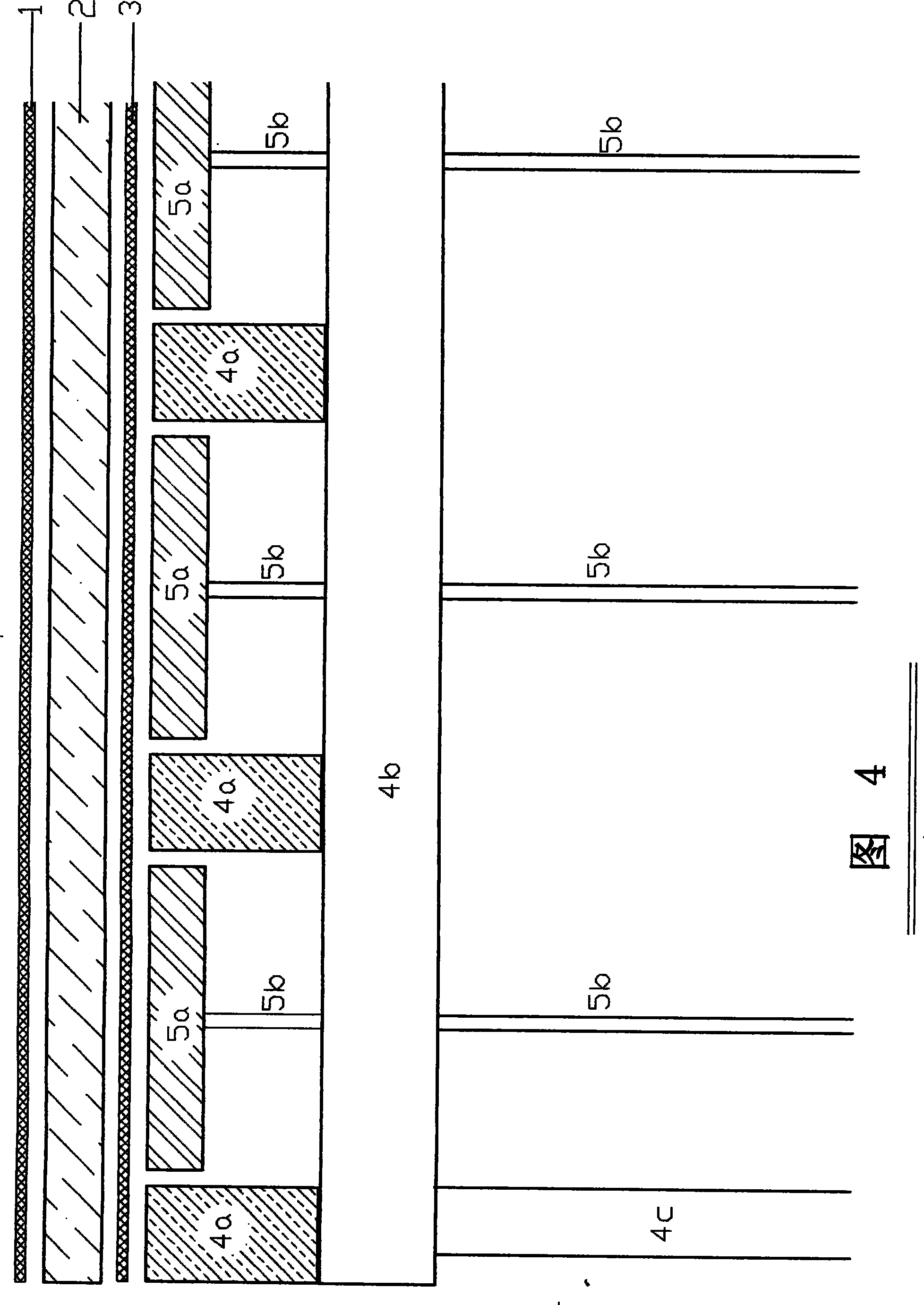

Template engineering construction technology employing coiled material

InactiveCN1769622AIncrease stiffnessSimple demouldingForming/stuttering elementsSupporting systemArchitectural engineering

The invention discloses a coil mould construction technique, which comprises the following parts: coil mould and support system, wherein the support system contains fixation support system and temporary support system; the mould support system is fixed basically, whose support force is more than the sum of static load and construction load, which avoids the waste of resource. The invention reduces the impaction of support system from vibrating force, which forms 'temporary composite board' of three overlapping coils in the new casting concrete and pressing condition.

Owner:孙长顺

Sunken water collecting and permeating device

The invention discloses a sunken water collecting and permeating device which is arranged under a soil layer and comprises a plurality of water gathering tanks, water gathering wing plates and cover plates. The water gathering tanks are long tanks, openings are formed in the upper sides of the long tanks, and the multiple water gathering tanks are sequentially connected with one another; the corresponding water gathering wing plates are obliquely and upwardly arranged on two sides of each water gathering tank, and permeation holes are formed in the surfaces of the water gathering wing plates; the cover plates are arranged on the tops of the water gathering tanks, and water through holes are formed in the surfaces of the cover plates. The sunken water collecting and permeating device has the advantages that the sunken water collecting and permeating device comprises the water gathering tanks which are arranged in underground environments, and water can be effectively drained when the underground water is saturated; the corresponding water gathering wing plates are arranged on the two sides of each water gathering tank and can assist in gathering the water when the underground water is saturated, the water can be led into the water gathering tanks, and the underground water can be permeated when not saturated; the sunken water collecting and permeating device has water collecting and permeating functions and is easy to lay and excellent in expandability and compatibility, and obvious effects can be realized.

Owner:ZHONGTAI INT HIGH NEW TECH CO LTD

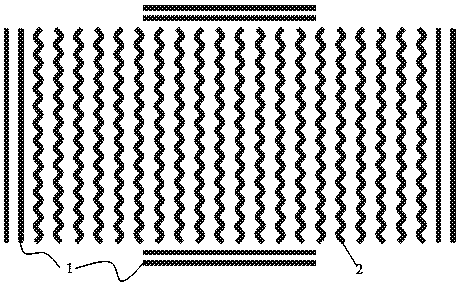

Horizontal fiber-laminated cement grass-planting parking lot and processing method thereof

InactiveCN108425524ASolve the large amount of engineeringIncrease stiffnessCultivating equipmentsPlant cultivationSites treatmentFiber

The invention discloses a horizontal fiber-laminated cement grass-planting parking lot and a processing method thereof. Several internal wavy netted cylinder dry-mixed mortar parts of the horizontal fiber-laminated cement grass-planting parking lot are in a wave shape and are parallel to one another; the wave crests of one internal wavy netted cylinder dry-mixed mortar part are close to the wave troughs of the internal wavy netted cylinder dry-mixed mortar part in the left adjacent row, and the two internal wavy netted cylinder dry-mixed mortar parts are sewed; the wave troughs of the internalwavy netted cylinder dry-mixed mortar part in the left adjacent row are separated from the wave crests of the internal wavy netted cylinder dry-mixed mortar part in the left adjacent row, and thus grass planting holes are formed. The horizontal fiber-laminated cement grass-planting parking lot has the advantage of effectively solving the problems that the paving work amount of a grass-planting parking lot is large, the parking lot is often crushed, construction is complicated, planted grass is easily damaged, site treatment causes ecological damage, and the project cost is high. The horizontal fiber-laminated cement grass-planting parking lot is high in rigidity and strength, paving is easy and fast, and the process is simple; there is no need to perform complicated treatment on a site, and ecological damage is avoided; besides, industrial production and transport are convenient, the project cost is reduced, and the construction quality is significantly improved.

Owner:SHENYANG JIANZHU UNIVERSITY

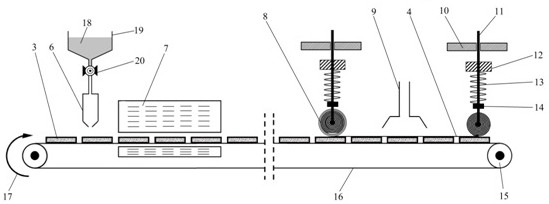

Electrostatic flocking flooring material easy to pave and preparation method of material

InactiveCN107007115AImprove anti-warping performanceImprove anti-static performanceCovering/liningsCoatingsPolyesterAdhesive

The invention provides an electrostatic flocking flooring material easy to pave and a preparation method of the material. The flooring material is of a layered structure and sequentially comprises a pile layer, a basic cloth layer and a backing layer from top to bottom. The basic cloth layer is any one of non-woven cloth, polyester-cotton blended plain cloth and polyester-cotton blended twill. The backing layer is made of a plastic or wood board. The pile layer is bonded to the basic cloth layer through an adhesive. The flooring material is blocky and can be spliced. A flocking blanket is easy to pave, pavement can be completed only through simple splicing, the procedure that the ground in the prior art is coated with glue is omitted, working hours are saved, the material is convenient to disassemble and replace, the edge warping prevention property is good, and the material is not easy to stain and high in fatigue resistance.

Owner:山东领潮新材料有限公司

Microcrystal wood floor and production process thereof

InactiveCN102250478AAnti-aging service lifeStable performanceCovering/liningsFlooringSoybean oilP-Cresol

The invention relates to a microcrystal wood floor, which is prepared from the following raw materials in part by weight: 70 parts of iron ore, mountain flour or crops, 25 parts of waste plastics and 5 parts of chemical auxiliary, wherein the chemical auxiliary is prepared from the following raw materials in part by weight: 40 parts of heat stabilizer, 15 parts of chlorinated polyethylene, 15 parts of soybean oil, 15 parts of white glue and 15 parts of antioxidant; the heat stabilizer is prepared from the following raw materials in part by weight: 40 parts of lead sulfate tribasic, 30 parts of dibasic lead sulfate and 30 parts of lead stearate; and the antioxidant comprises tert-butyl-p-cresol. The invention has the advantages that: the microcrystal wood floor is water resistant, does not deform, arch, crack or rot, and is ageing resistant, long in service life, stable in performance, labor-saving and time-saving; and in the production process, three wastes cannot be generated, and waste products generated can be crushed and recycled.

Owner:李存社

Anticorrosion mothproof cork floor

InactiveCN105507547ALight in massIncrease elasticityAntifouling/underwater paintsPaints with biocidesSurface layerEngineering

The invention discloses an anticorrosion mothproof cork floor. The anticorrosion mothproof cork floor comprises a base material layer, a cork layer and a surface layer, wherein the base material layer is composed of plastic or rubber products, the cork layer and the base material layer are spliced in a staggered manner by glue, staggered splicing refers to L-shaped staggered splicing, a margin between the cork layer and the base material layer ranges from 1.5cm to 4.5cm, the length and the width of the base material layer are slightly smaller than those of the cork layer, and the surface layer covers the cork layer completely. The anticorrosion mothproof cork floor has the advantages that by the aid of special coating, living things harmful to wood, such as moths and white ants, can be killed effectively, and anticorrosion and mothproof properties of the cork floor are achieved.

Owner:山西碳金科技有限公司

Preparation method and application of cork prepolymer and construction method of cork floor

ActiveCN110983912AAccelerated corrosionGood water permeabilityPaving gutters/kerbsSidewalk pavingsPolymer sciencePolyurethane adhesive

The invention discloses a preparation method and an application of a cork prepolymer and a construction method of a cork floor, and belongs to the field of cork floors. Cork or oak bark is used as a raw material to prepare cork particles, and the cork particles are treated to obtain the cork prepolymer. The preparation method comprises the following steps: stirring and mixing the cork particles and polyurethane to obtain a mixed material; carrying out baking hardening in a baking channel and normal-temperature hardening on the mixed material to harden the cork particles and the polyurethane into an agglomerated polymer; stirring, crushing and separating the polymer, adding a single-component rigid polyurethane adhesive, and uniformly stirring and mixing; after stirring is completed, carrying out baking hardening in a baking channel and normal-temperature hardening again to enable the polymer to be in an agglomerated state; and then stirring and crushing the polymer again, and crushingthe blocks into single particles to obtain the granular cork prepolymer. According to the preparation method, the cork particles are firstly treated to obtain the cork prepolymer, and the surface of the cork prepolymer is fully coated with polyurethane, so that the hardness and the impact strength of cork can be improved.

Owner:聊城森盟工艺品有限公司

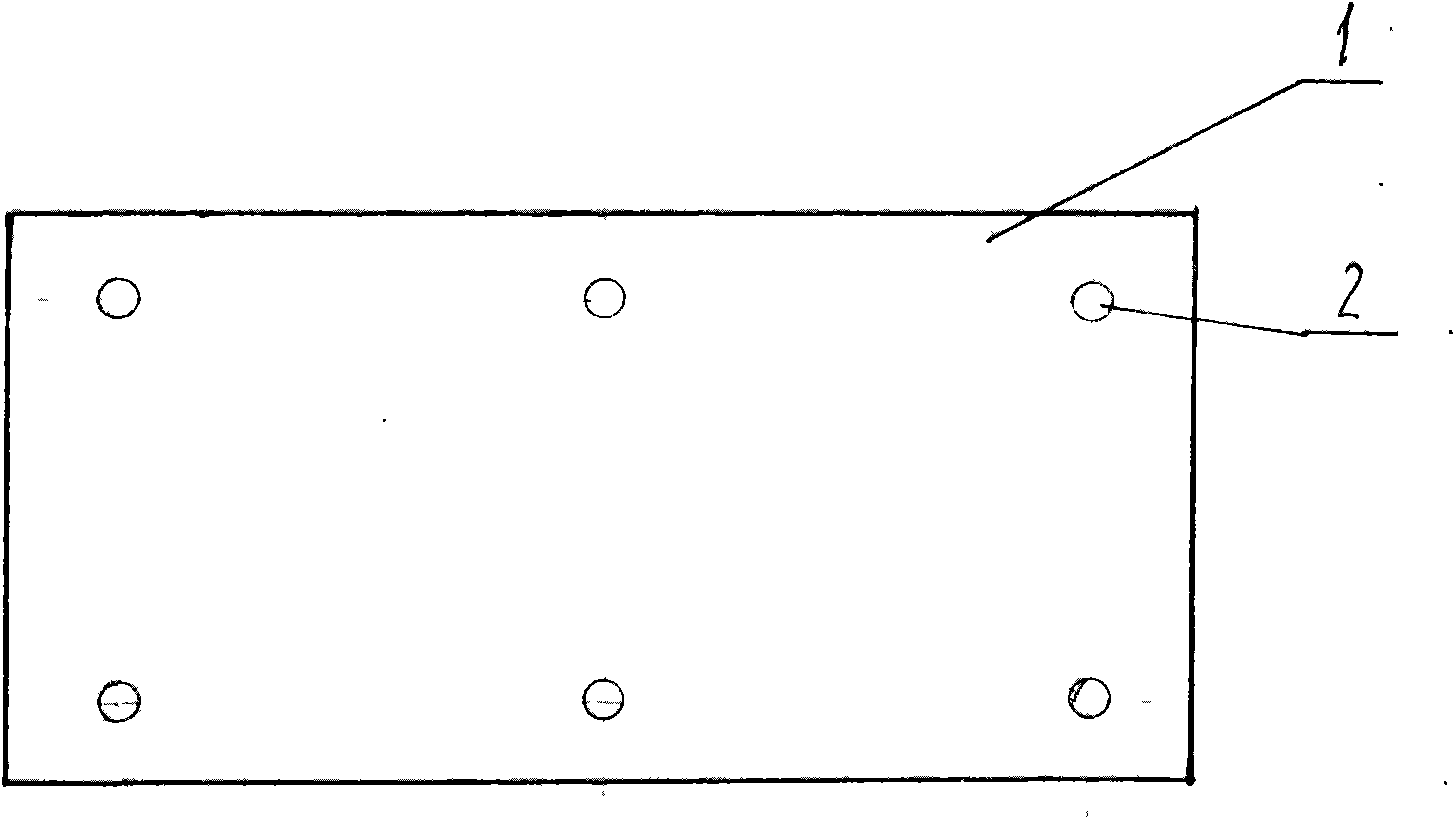

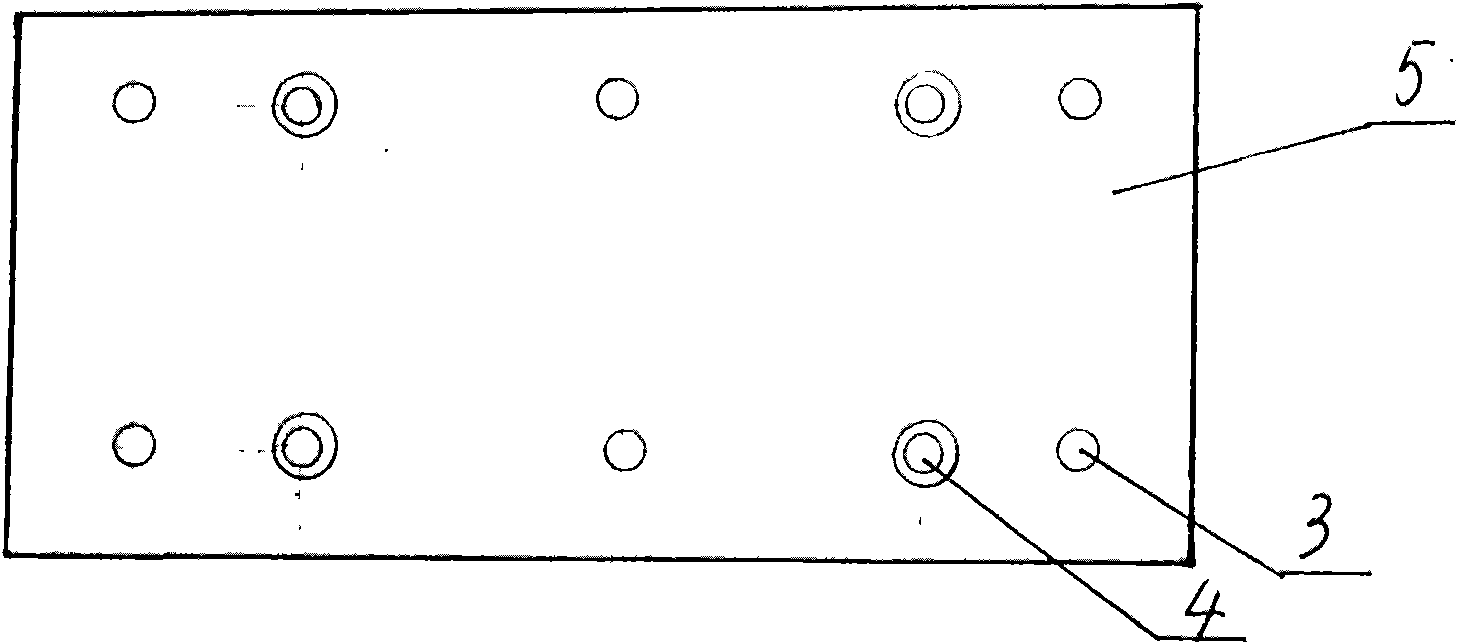

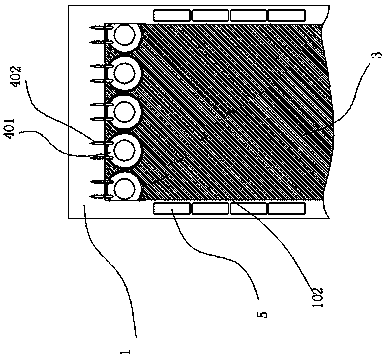

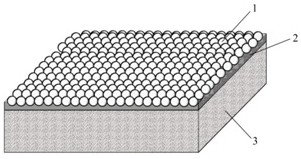

Particle-embedded photocatalytic pollution-cleaning veneer brick and its preparation method and preparation device

ActiveCN110452021BImprove stabilityHigh bonding strengthWater/sewage treatment by irradiationWater treatment compoundsWater flowPhoto catalysis

The invention discloses a particle-embedded photocatalytic pollution-cleaning veneer brick, a preparation device for a particle-embedded photocatalytic pollution-cleaning veneer brick and a preparation method for a particle-embedded photocatalytic pollution-cleaning veneer brick, comprising A plurality of microbeads (1), an inlay layer (2) and a substrate (3), the inlay layer (2) is fixedly arranged on the upper surface of the substrate (3), and the surface of the plurality of microbeads (1) is coated with nano-titanium dioxide , a plurality of microbeads (1) are fixedly arranged on the upper surface of the embedded layer (2). The embedded composite veneer brick prepared by the present invention has a three-layer structure, and the silicone resin and the ceramic substrate as the intermediate connection layer have high bonding strength, and the microbeads are embedded in the silicone resin layer under pressure It can also have high stability, so that the prepared chimeric composite veneer brick can have good load stability and water erosion resistance, and is suitable for adapting to various water flow conditions.

Owner:HOHAI UNIV

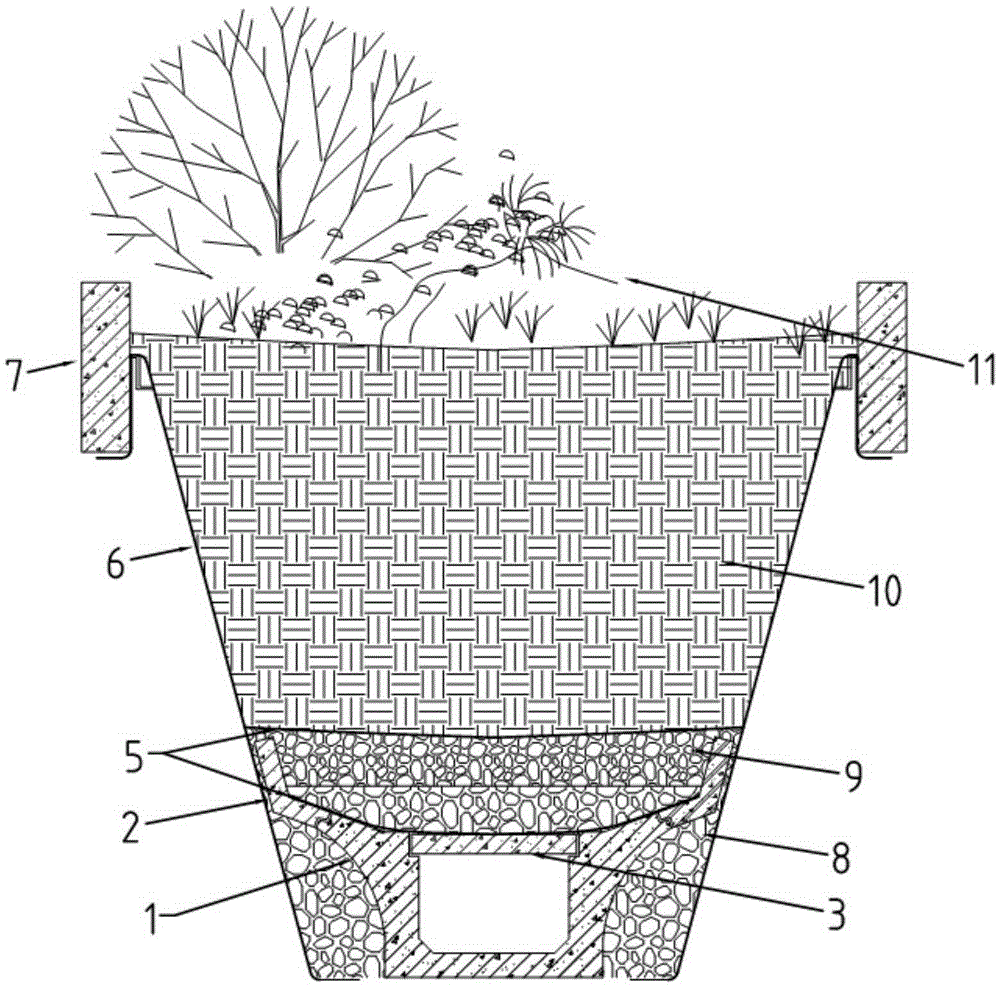

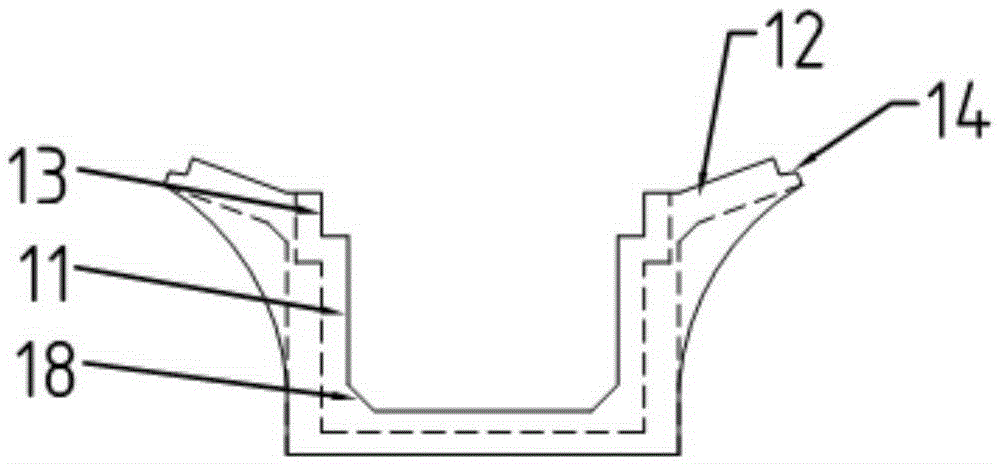

A green roof device

ActiveCN108842970BSimple structureSolving Thermal Bridge ConundrumsRoof coveringReceptacle cultivationBuilding energyArchitectural engineering

The invention belongs to the field of building energy conservation, and particularly relates to a greening phase-change box bridge. The greening phase-change box bridge is used for connecting greeningphase-change boxes and comprises a joint and connectors movably arranged inside the joint; the joint comprises four connecting ports; the connecting ports communicate with one another in the warp andweft directions of the joint; the connectors are inserted in the connecting ports and are made of plastic; cavities are formed inside the connectors; and IXPE foam is arranged inside the cavities. Each greening phase-change box comprises a flower disk, a tray and an energy storage disk which are assembled up and down; and phase-change materials are lid inside the flower disk, the tray and the energy storage disk. According to the bridge, the phase-change materials are lid inside the flower disks, the trays and the energy storage disks, and when the outside temperature changes, the phase-change materials absorb or release heat to play a role in heat insulation for a roof; and the multiple greening phase-change boxes are assembled and combined according to the roof design, so that the lightplanting roof heat insulation system can be formed.

Owner:JIANGNAN UNIV

Method for paving wood grain bamboo floor

The invention discloses a method for paving a wood grain bamboo floor, which comprises the following steps of: paving keels; paving a moisture-proof film; installing a floor; and scattering camphor wood blocks in a gap between adjacent keels. The floor can be effectively prevented from being cracked or arched, or generating abnormal sound, and the like after being paved, has the advantages of attractive appearance after being paved, and the like, and is convenient and easy to pave.

Owner:SHENZHEN LIJIE DECORATION DESIGN CO

A green phase change box

ActiveCN108966930BImprove protectionPromote growthRoof coveringReceptacle cultivationWater storageBuilding energy

Owner:JIANGNAN UNIV

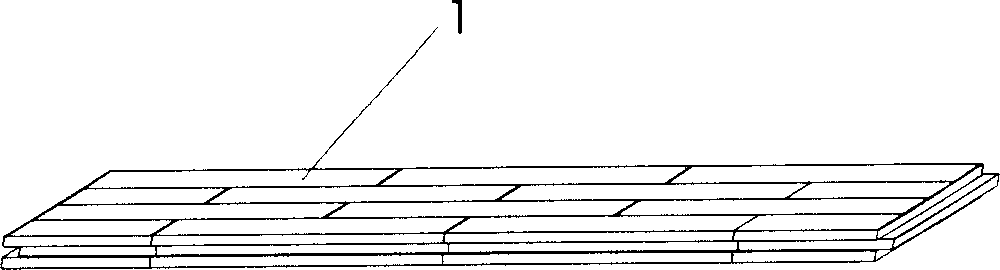

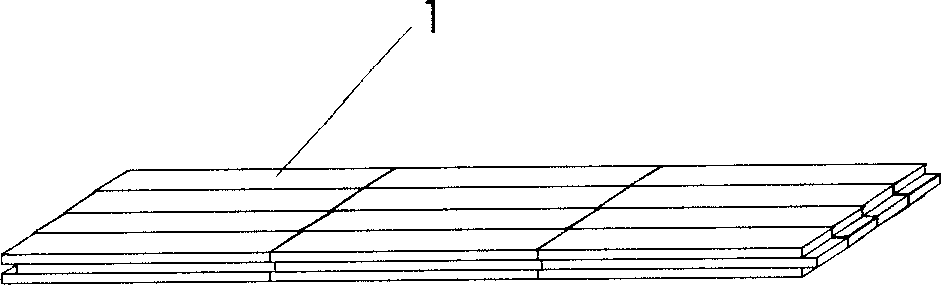

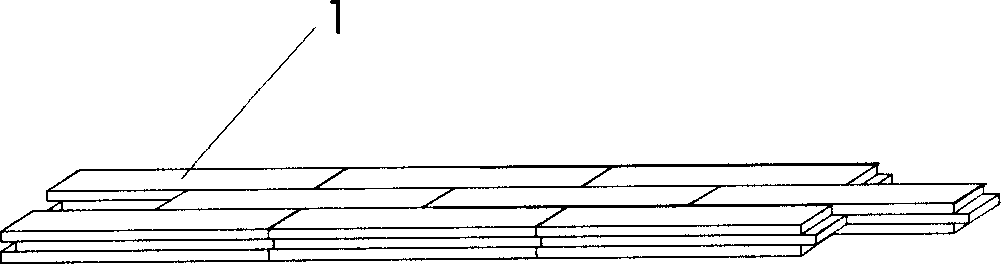

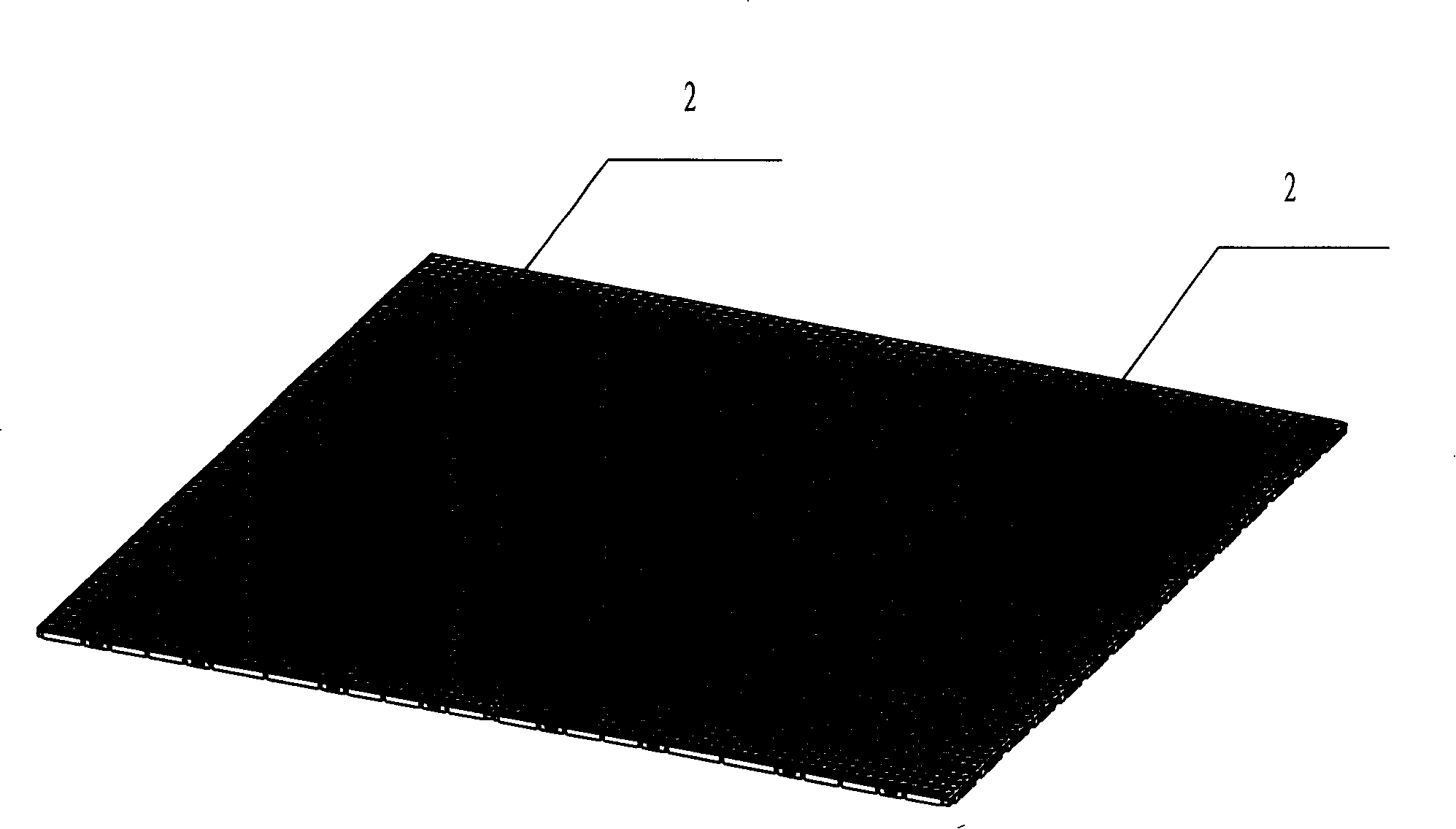

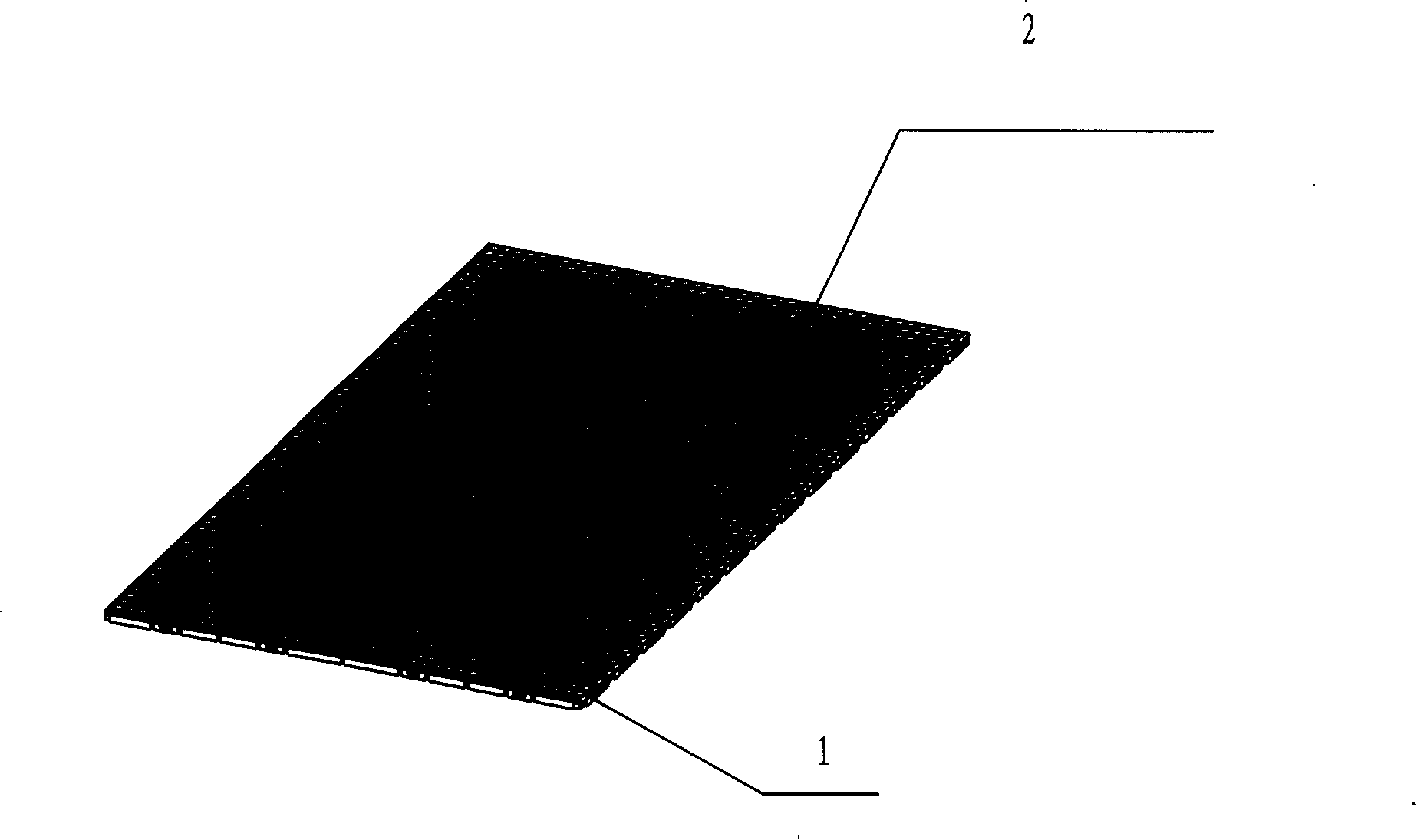

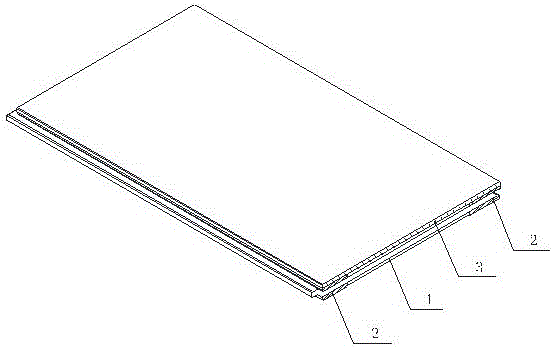

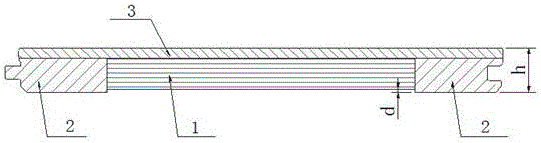

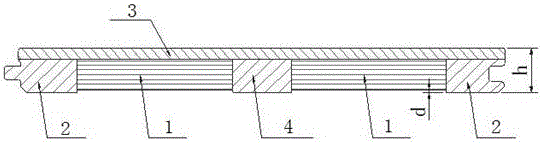

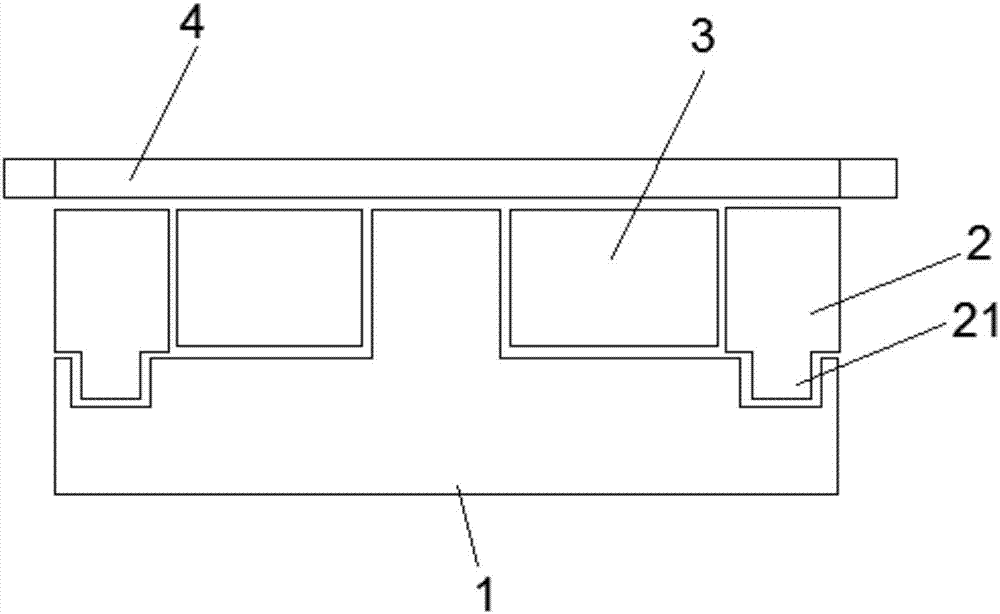

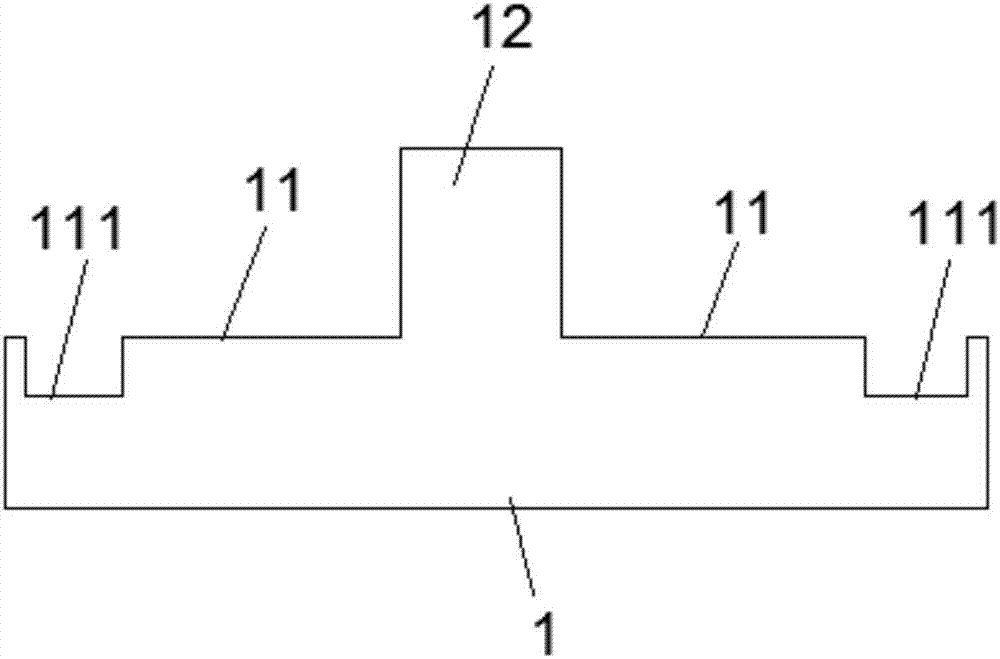

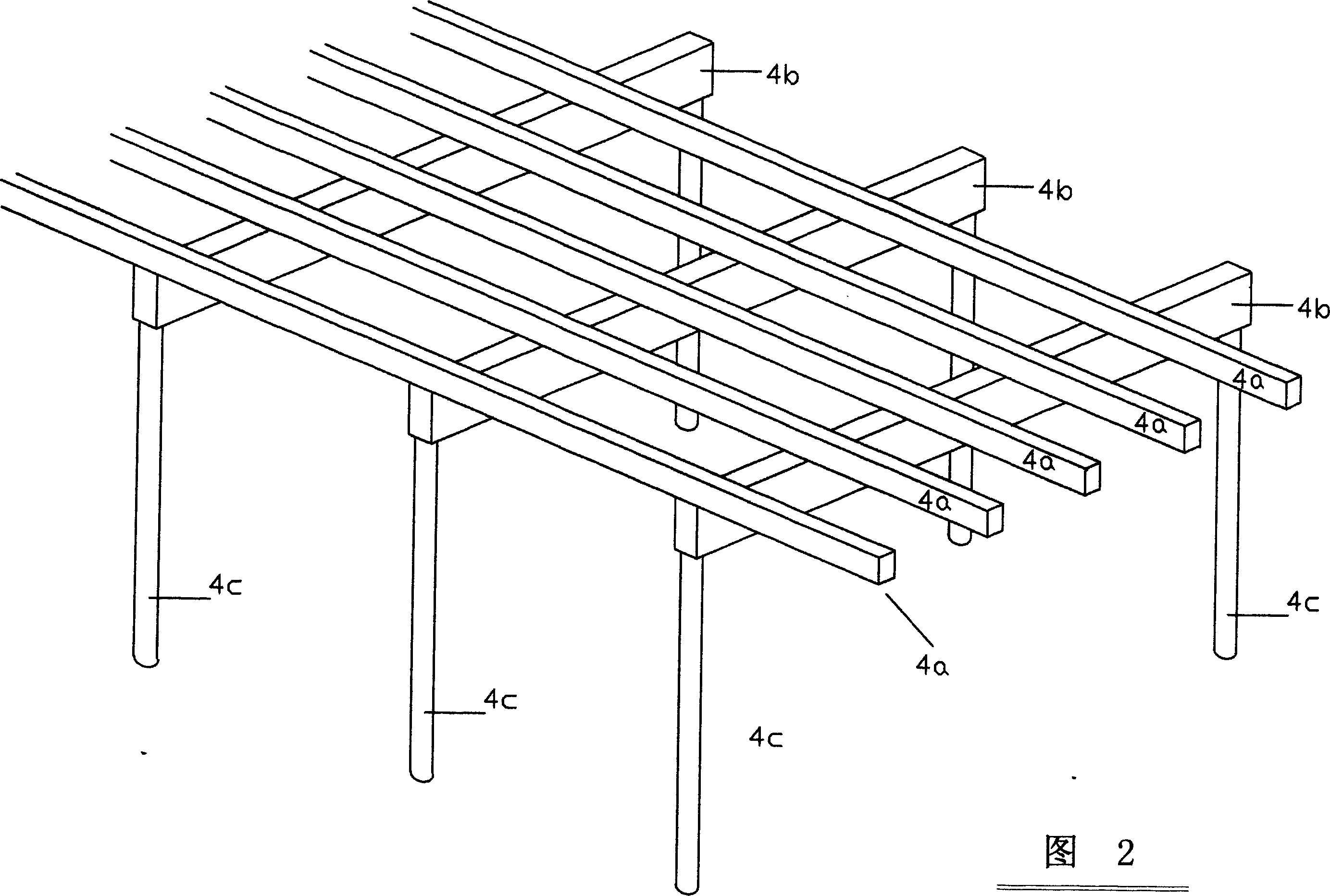

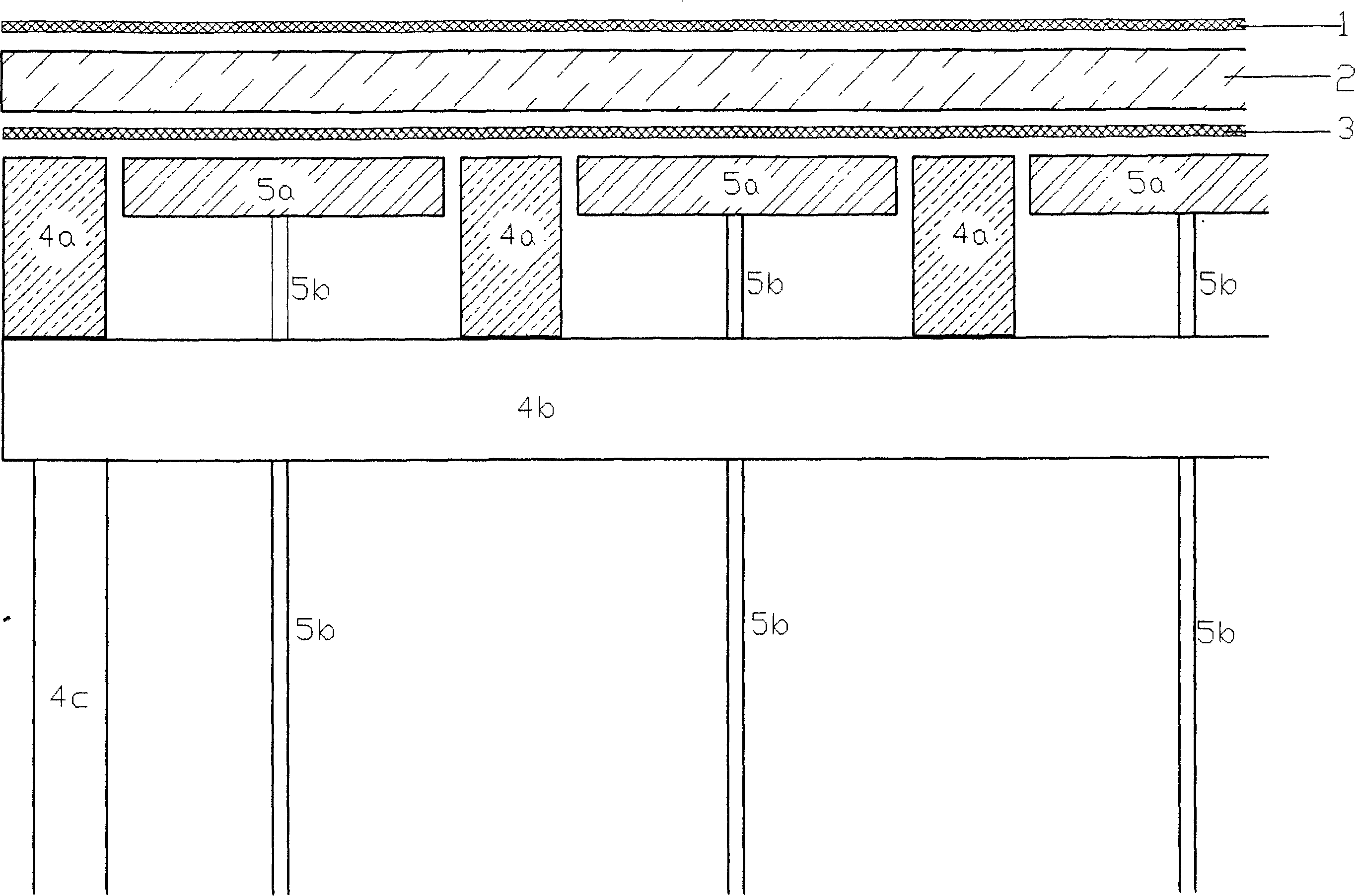

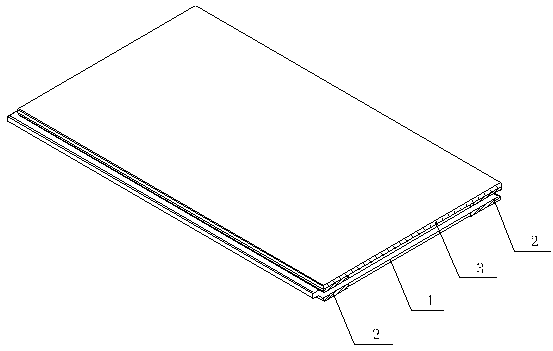

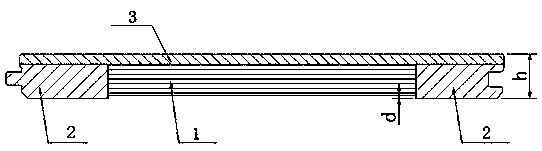

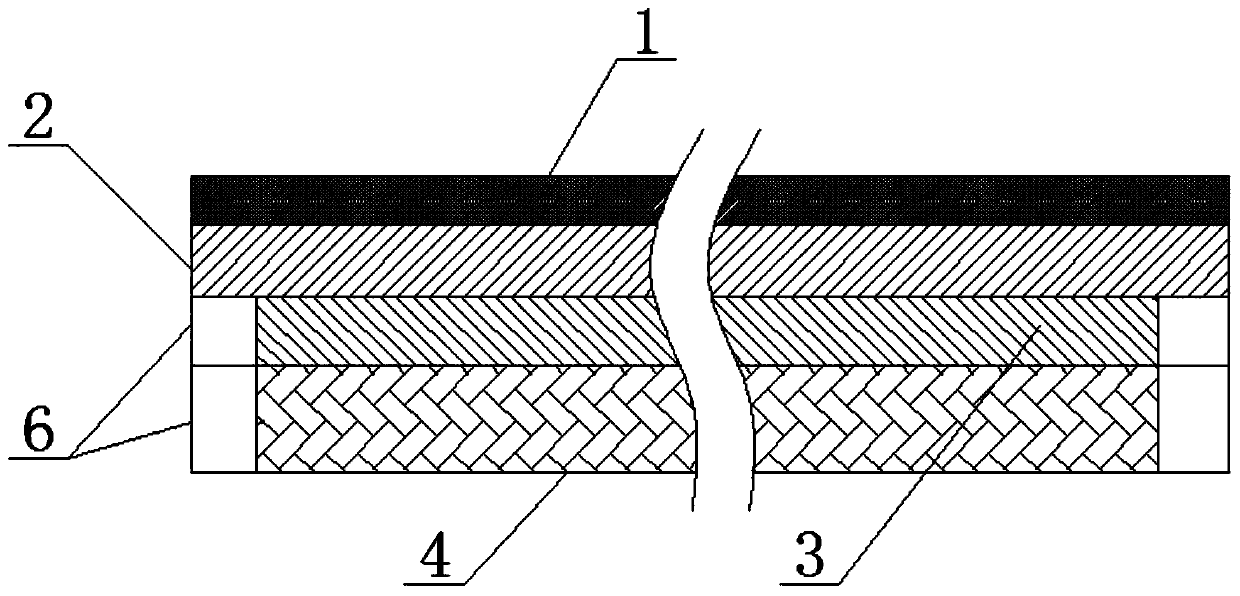

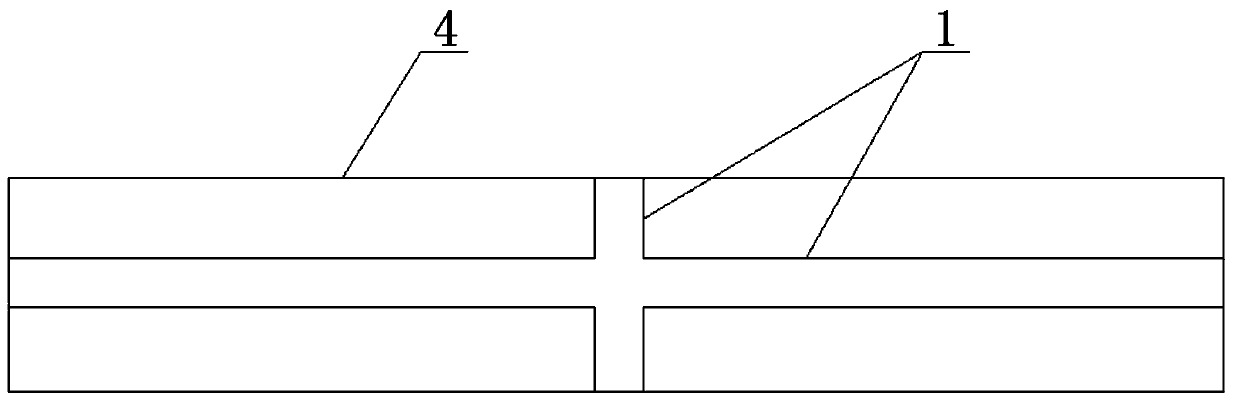

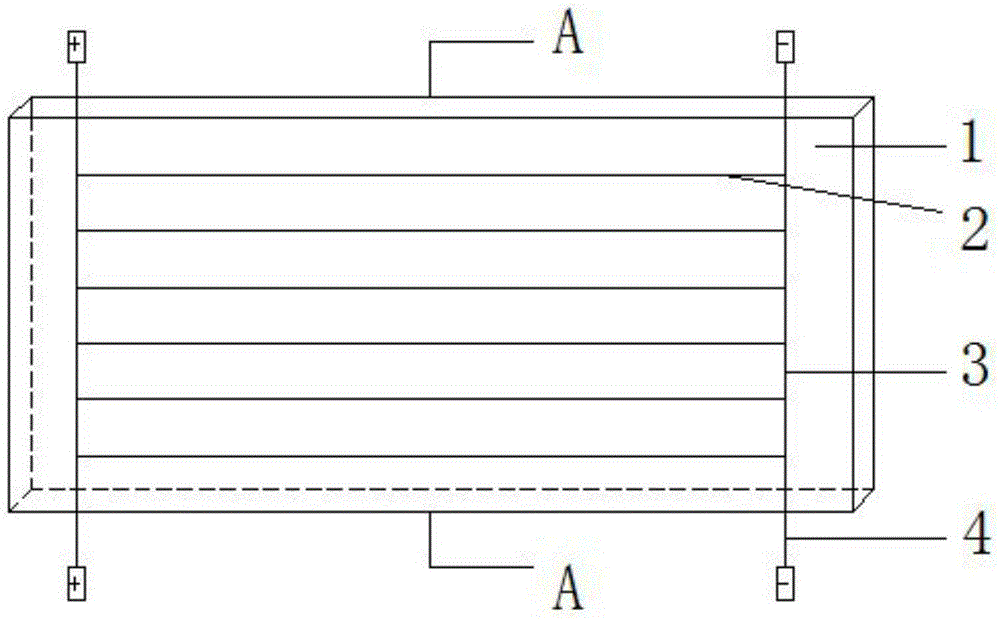

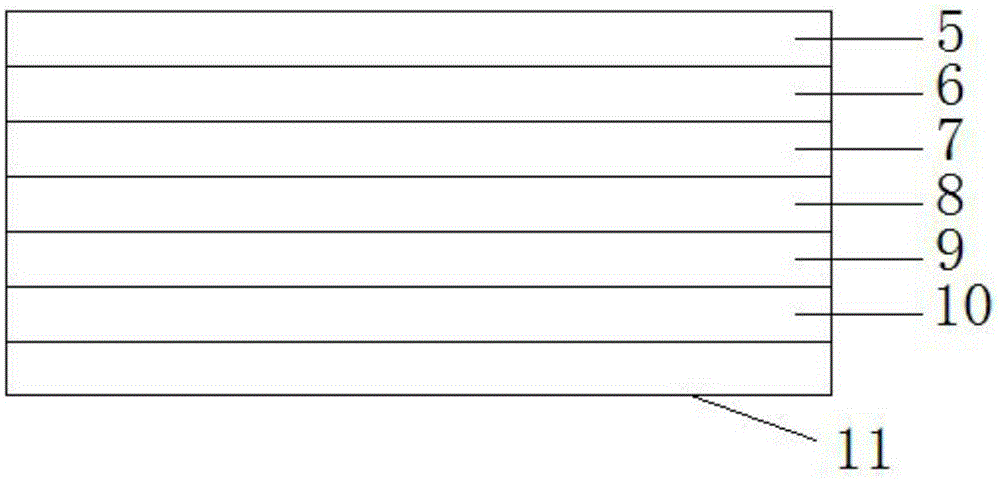

A second-floor floor based on beam bridge structure

InactiveCN106049820BSimple pavingLow costLayered productsWood veneer joiningQuality levelEngineering

The invention provides a two-layer floor based on a beam bridge structure. The two-layer floor is characterized by comprising core boards, edgings, a veneer and reinforcing strips, wherein the core boards, the edgings and the reinforcing strips constitute a floor base material, the edgings are connected with the two sides in the width direction of the core boards in a splicing mode, and one or more reinforcing strips are added to the middle of the two core boards. A processing technology of the two-layer floor includes the first step of splicing the core boards, the second step of determining the thickness of the core boards, the third step of assembling the floor base material, the fourth step of determining the thickness of the floor base material, the fifth step of covering the floor base material with the veneer, and the sixth step of forming the floor. The two-layer floor has the advantages that firstly, the two-layer floor is easy to lay, low in cost and small in residual stress; and secondly, due to the beam bridge structure, air on the back of the laid floor can circulate, the deformation probability of the floor is reduced, the quality level of the two-layer floor can be remarkably improved, and the life cycle of the two-layer floor can be remarkably prolonged.

Owner:GUANGDONG YIHUA TIMBER IND

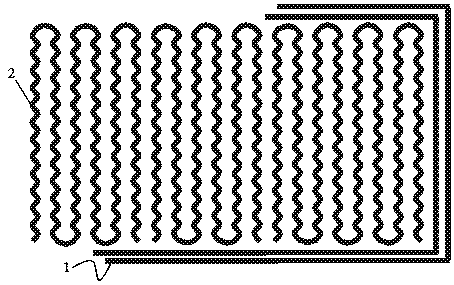

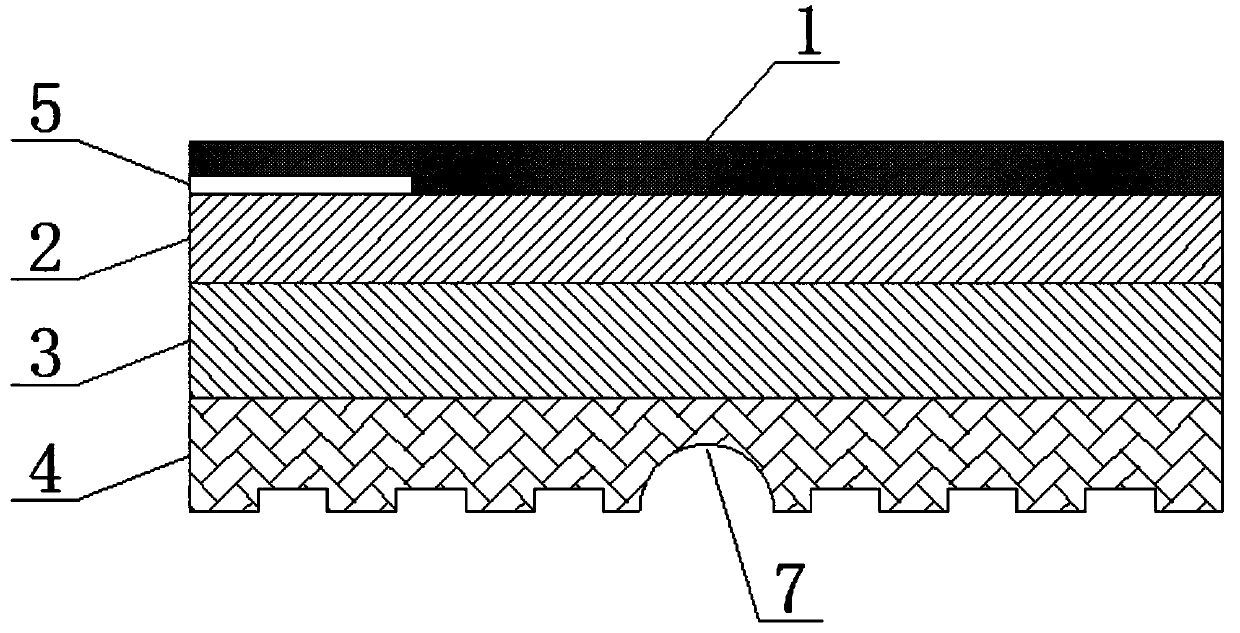

Composite floor for floor heating and mounting method of composite floor

InactiveCN109707129AReduce laying stepsRealize integrationLighting and heating apparatusElectric heating systemTemperature controlKeel

The invention discloses a composite floor for floor heating and a mounting method of the composite floor. The composite floor for floor heating comprises a protective layer, a heating layer, a heat preservation layer and a base layer; the protective layer is a plastic coating with the thickness being 1-2 mm, wherein the surface of the heating layer is coated with the plastic coating; the heating layer is a platy electric heating heat emitting device; the lower side face of the heating layer is bonded with the heat preservation layer, the base layer is arranged below the heat preservation layer, and keels are adopted as the base layer; the composite floor for floor heating further comprises a temperature measuring head and temperature control equipment; the temperature measuring head is tightly connected with the heating layer, and the end of the heat preservation layer is provided with a groove for wiring; the end of the base layer is provided with a groove for wiring, and the bottom of the base layer is provided with wire passing grooves; and the wire passing grooves are two straight grooves which are staggered into a cross shape. The invention further provides the mounting methodfor laying the composite floor for floor heating. The laying process is simple, and the construction time and the labor force are reduced greatly.

Owner:林文杰

Template engineering construction technology employing coiled material

InactiveCN1769622BIncrease stiffnessSimple demouldingForming/stuttering elementsSupporting systemArchitectural engineering

Owner:孙长顺

Greening phase-change box

ActiveCN108966930AImprove protectionPromote growthRoof coveringReceptacle cultivationPhase-change materialEngineering

The invention belongs to the field of building energy conservation and particularly relates to a greening phase-change box. The greening phase-change box comprises a flowerpot, a tray and an energy storage plate, wherein the flowerpot, the tray and the energy storage plate are connectedly and vertically assembled and internally provided with a phase-change material by laying. By laying of the phase-change material in the flowerpot, the tray and the energy storage plate, when the external temperature changes, a roof heat insulation effect is achieved through the phase-change material which absorbs or releases heat. Special planting soil can be laid on the phase-change material of the flowerpot, crassulaceae such as sedum makinoi or araceae perennial herbaceous plants can be planted for greening a roof environment, the phase-change material in the flowerpot plays a role in water storage, and plant root growth is promoted. A lightweight planting roof heat insulation and preservation system can be formed by assembly of multiple greening phase-change boxes according to the roof design.

Owner:JIANGNAN UNIV

Static electricity heating healthcare decorative plate and method for mounting same

InactiveCN105332493APlay a role in heatingPlay a role in health careLighting and heating apparatusElectric heating systemFiberCarbon fibers

The invention discloses a static electricity heating healthcare decorative plate and a method for mounting the same, and belongs to the technical field of decoration engineering. The static electricity heating healthcare decorative plate comprises a wood-plastic plate, clamp fasteners, back plates, a plurality of grooves, carbon fibers, two flat copper wires and power conducting wires. The clamp fasteners and the back plates are arranged on the side surfaces of the wood-plastic plate and are used for splicing, the grooves are transversely equidistantly formed in the back surface of the wood-plastic plate, the carbon fibers are respectively arranged in the multiple grooves, two ends of each carbon fiber are respectively connected with two ends of the corresponding carbon fiber in parallel by the two flat copper wires, and the corresponding power conducting wires are respectively led out from two ends of each flat copper wire. The static electricity heating healthcare decorative plate and the method have the advantages that static electricity can be generated by the static electricity heating healthcare decorative plate owing to carbon fiber implantation technologies, the static electricity heating healthcare decorative plate is low in power consumption and easy to lay, and heating elements are difficult to age.

Owner:范东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com