Anticorrosion mothproof cork floor

A cork floor and moth-proof technology, applied to biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of moth-eaten and cork perishable, and achieve the characteristics of moth-eaten prevention and sound insulation. , good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

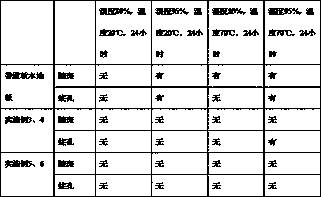

Examples

Embodiment 1

[0014] 20 parts of methyl methacrylate, 20 parts of bakelite powder, 15 parts of ethyl acetate, 30 parts of ethylene glycol monoethyl ether, 20 parts of limonene, 5 parts of phthalic anhydride, 0.5 parts of defoamer, 0.5 parts of leveling agent 0.5 parts of wetting agent, 10 parts of mica powder, 15 parts of filler and 2 parts of pigment.

[0015] The leveling agent is composed of polyacrylate copolymer and fluorocarbon modified polyacrylate; the defoamer can be polyurethane special defoamer, the main component is modified silicone; the wetting agent is polyether modified dimethyl The main component is siloxane copolymer solution; the filler is titanium dioxide or talcum powder or a combination of both.

[0016] Preparation process: Add methyl methacrylate, bakelite powder and ethyl acetate into the reaction kettle for stirring, the stirring speed is 200 rpm, the temperature is raised to 150°C during the stirring process, then add ethylene glycol monoethyl ether and limonene, ...

Embodiment 2

[0018] 20 parts of methyl methacrylate, 20 parts of bakelite powder, 15 parts of ethyl acetate, 30 parts of ethylene glycol monoethyl ether, 20 parts of limonene, 5 parts of phthalic anhydride, 0.5 parts of defoamer, 0.5 parts of leveling agent 0.5 parts of wetting agent, 10 parts of mica powder, 15 parts of filler, 2 parts of pigment and 1 part of lichen extract.

[0019] The leveling agent is composed of polyacrylate copolymer and fluorocarbon modified polyacrylate; the defoamer can be polyurethane special defoamer, the main component is modified silicone; the wetting agent is polyether modified dimethyl The main component is siloxane copolymer solution; the filler is titanium dioxide or talcum powder or a combination of both.

[0020] Preparation process: Add methyl methacrylate, bakelite powder and ethyl acetate into the reaction kettle for stirring, the stirring speed is 200 rpm, the temperature is raised to 150°C during the stirring process, then add ethylene glycol mono...

Embodiment 3

[0022] High-density polyethylene and butyl rubber are used as the substrate layer, natural cork is used as the cork layer, and the film formed by the coating obtained in Example 1 is used as the surface layer. The base material layer and the cork layer are equal in size and spliced in dislocation. Dislocation stitching means that at least one of the horizontal length and vertical width of the upper structure is not aligned with the horizontal length and vertical width of the lower structure. When the cork floor board is used to lay the cork floor board, multiple cork floor board boards can be fastened and relatively fixed through the dislocation splicing structure. After fixing, cover the surface layer all over the cork layer. Namely get cork flooring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com