Convenient brick grass and manufacture method thereof

A manufacturing method and technology of brick grass, applied in the application, cultivation, agriculture and other directions, can solve the problems of complex production process, high transportation cost, small unit volume, etc., and achieve the effects of convenient transportation, high transportation cost and small unit volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

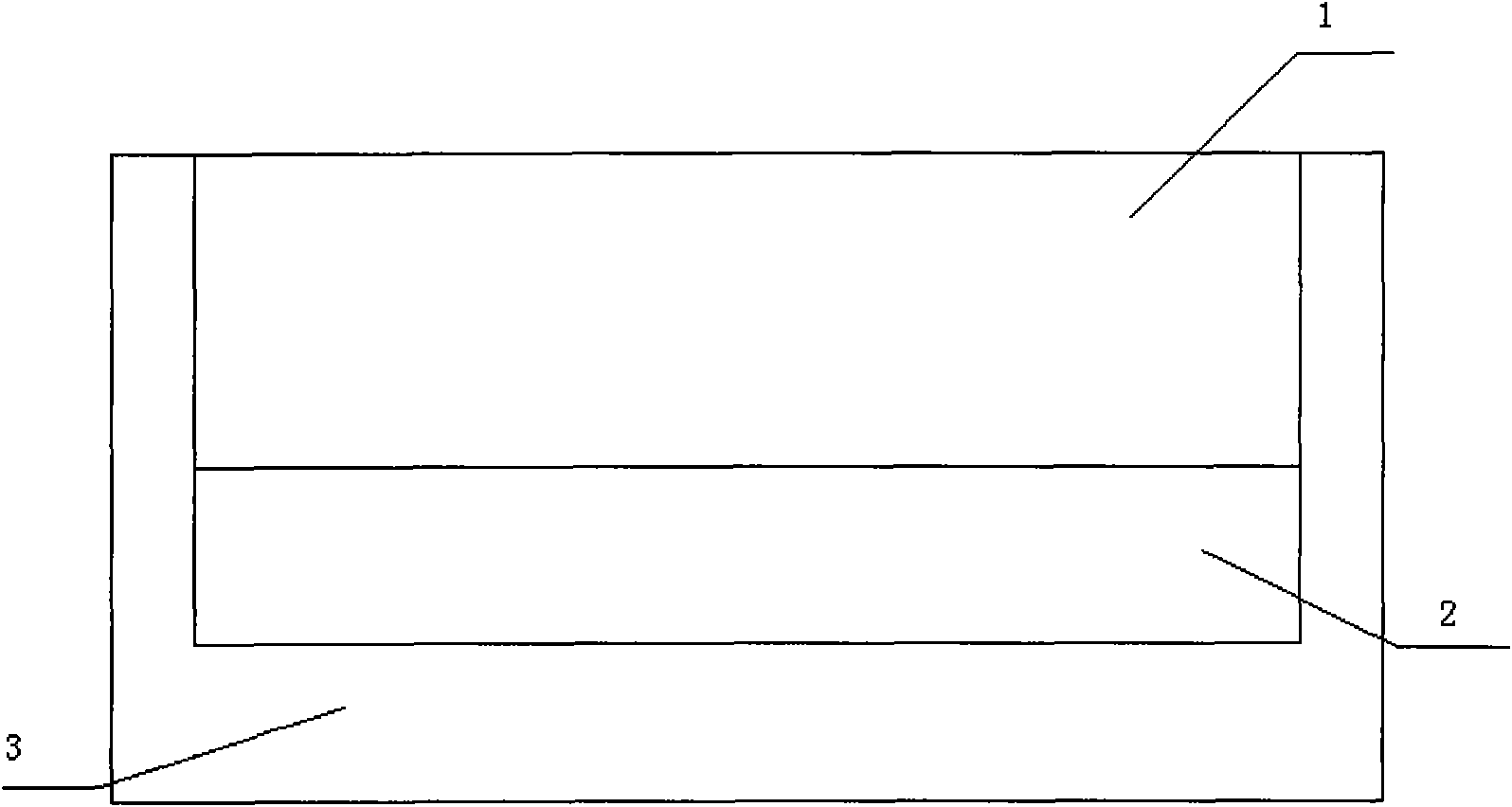

[0022] A convenient brick grass and its manufacturing method: the convenient brick grass is divided into three parts from top to bottom, called the upper layer 1, the middle layer 2, and the base 3; the upper layer 1 is formed by mixing and compressing organic fertilizer, clay, and seeds; The mixed layer of water-retaining agent and clay is compression-molded, and the base is compressed-molded by mixing herbicide, water and soil.

[0023] A convenient brick grass and a manufacturing method thereof, the manufacturing method comprising the following steps:

[0024] (1) Take organic fertilizer and clay from the upper layer and put them into a concrete mixer in a ratio of 1:1.5 and mix them into a mold for compression (compression ratio 1:0.98). The thickness of the soil layer after compression is 1.5cm. Sow the seeds; or mix the organic fertilizer and clay and spread the seeds on the top layer in proportion and compress them at the same time;

[0025] (2) Take water-retaining ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com