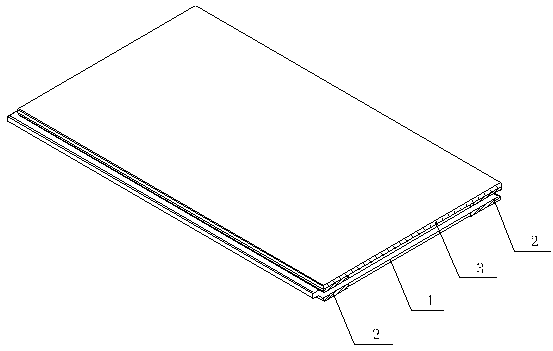

A second-floor floor based on beam bridge structure

A floor and core board technology, applied in the direction of layered products, building structures, and the joining of wooden veneers, can solve problems such as easy deformation, and achieve low cost, easy installation, improved quality and life cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

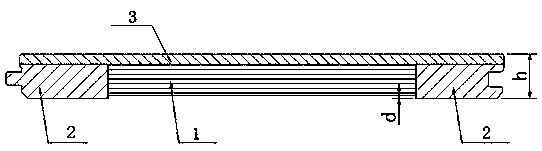

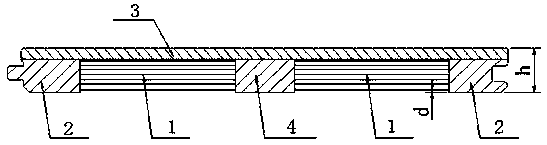

[0040] (1) Core board splicing: The pine core board material is made into a unit board with a length of 300mm-450mm, a width of 50mm, and a thickness of 17mm. The section of each unit board is not allowed to have visible collapse or material decay. Groove and tenon connection or adhesive bonding, splicing to a length of 910mm in the width direction of the unit board to form a flat core board 1, wherein the length direction of the unit board and the length direction of the core board 1 are perpendicular to each other, and the unit board passes through the width direction The splicing forms the length of the core board;

[0041] (2) Determine the thickness of the core board: sand the core board 1 on a sanding machine to a thickness of 16mm, and then cut it in the width direction of the core board. The precise width is 150mm, and the width direction is parallel to the width direction of the final floor board ;

[0042] (3) Substrate assembly: through groove and tenon connection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com