Particle-embedded photocatalytic pollution-cleaning veneer brick and its preparation method and preparation device

A preparation device and chimeric technology, applied in chemical instruments and methods, light water/sewage treatment, clay products, etc., can solve the problems of low structural strength and high cost, and achieve simple paving, low production cost, and application fields wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

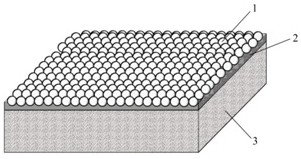

[0045] A particle-embedded photocatalytic decontamination veneer brick, comprising a plurality of microbeads 1, an inlay layer 2 and a substrate 3, the inlay layer 2 is fixedly arranged on the upper surface of the substrate 3, and the surface of the plurality of microbeads 1 is coated Nano-titanium dioxide, a plurality of microbeads 1 are fixedly arranged on the upper surface of the embedding layer 2 .

[0046] Further, the microbead 1 is a transparent sphere, and the substrate 3 is a sheet-like structure; the components of the substrate 3 include coal ash, clay, shale, sludge, slag, bauxite and coal gangue, and the surface of the microbead 1 is made of Coated with silicone resin and nano-titanium dioxide from the inside to the outside; multiple microbeads 1 are closely arranged on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com