Horizontal fiber-laminated cement grass-planting parking lot and processing method thereof

A horizontal fiber and parking lot technology, which is applied in the field of grass planting parking lot, can solve the problems of grass planting parking lot being crushed, grass planting is easy to damage, and high engineering cost, and achieves the effect of improving construction quality, simple process, and avoiding ecological damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

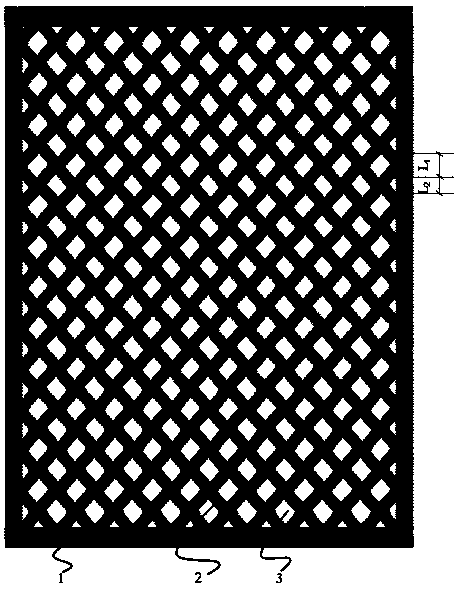

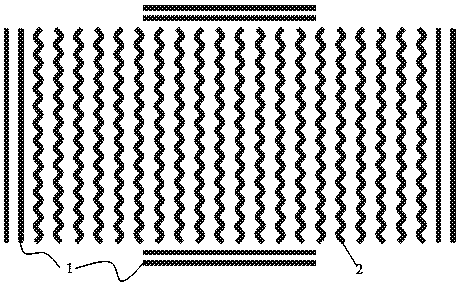

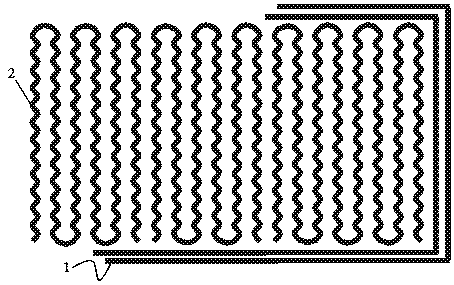

[0033] Example: such as Figure 1~Figure 3 As shown, the dry-mixed mortar 2 of the inner wavy mesh cylinder is wavy, and the dry-mixed mortar 2 of the inner wavy mesh cylinder is arranged side by side with each other. The troughs of the dry-mixed mortar 2 in the inner wavy mesh tube are close and stitched together, and the troughs of the dry-mixed mortar 2 in the inner wavy mesh tube are separated from the crests of the adjacent row on the left to form a grass planting hole 3; The trough of the mesh cylinder dry-mixed mortar 2 is close to and stitched with the crest of the internal wavy mesh cylinder dry-mixed mortar 2 in the adjacent row on the right. The troughs in adjacent rows are separated from each other to form grass planting holes 3;

[0034] The cross-section of the dry-mixed mortar 2 of the inner wavy mesh tube is rectangular, and at the joint of the dry-mixed mortar 2 of the inner wavy mesh tube, the top and bottom of the dry-mixed mortar 2 are stitched together, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com