Municipal road passive safety device and mounting method thereof

A passive safety and municipal road technology, applied in road safety devices, roads, roads, etc., can solve problems such as high temperature, locking, vehicle rollover, ground subsidence, etc., to reduce large-scale traffic accidents, simple molding conditions, reduce vehicle damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

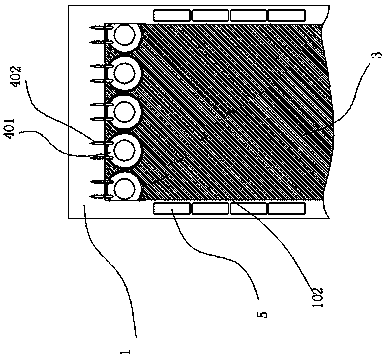

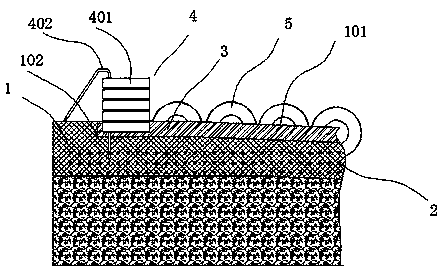

[0035] refer to figure 1 and figure 2The shown passive safety device for municipal roads comprises a concrete layer 1 poured on the ground, the pouring thickness of the concrete layer is 50cm, the longitudinal width of the pouring of the concrete layer is 300cm, and the inside of the concrete layer 1 is poured with Reinforcement cage 2, the upper and lower sides of the reinforcement cage are provided with multiple layers in parallel, and a slope 101 with a slope of 3.5° is formed after the concrete layer 1 is poured. The horizontal length of the concrete layer 1 after pouring is 240 meters, the load of the truck is relatively large, and the braking distance of Xiangyin is also relatively long. After pouring on the slope 101, a sunken foundation pit is formed. 102, the depth of the foundation pit 102 is 14 cm, and the buffer mixture 3 is tiled in the foundation pit 102. The setting of the foundation pit 102 is mainly to fill the buffer mixture 3. When the vehicle is running, ...

Embodiment 2

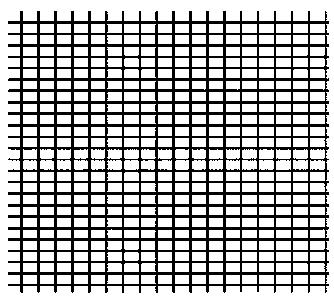

[0037] refer to image 3 As shown, each layer of reinforcement cage 2 includes a plurality of threaded steel bars arranged in a horizontal and vertical staggered manner. The diameter of the threaded steel bars is 10mm, and the staggered positions of the threaded steel bars are bound and fixed by steel binding wires. The distance between horizontally adjacent threaded steel bars is 24cm, and the spacing between longitudinally adjacent rebars is 20cm.

Embodiment 3

[0039] The buffer mixture 3 includes 30% medium sand, 25% stones, and 45% melon seeds. When laying flat, it is mixed by mixing equipment before laying; the above-mentioned materials are simple and easy to obtain, and after being stressed, It has good deformation ability and is easy to cooperate with the wheels to achieve deceleration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com