Ribbed precast component template for buildings

A technology for prefabricated components and construction, applied in the direction of molds, etc., can solve the problems of increased construction time and construction difficulty, cumbersome production, and difficult demolition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

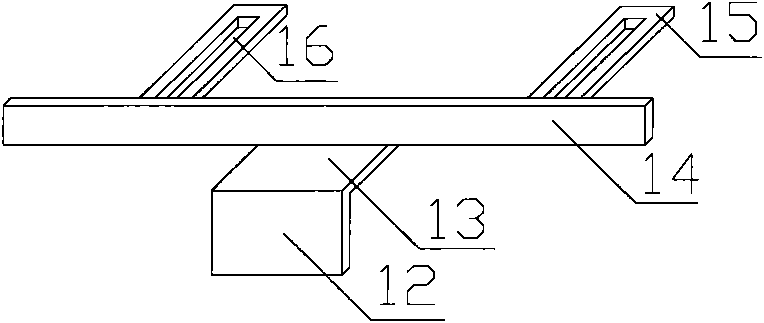

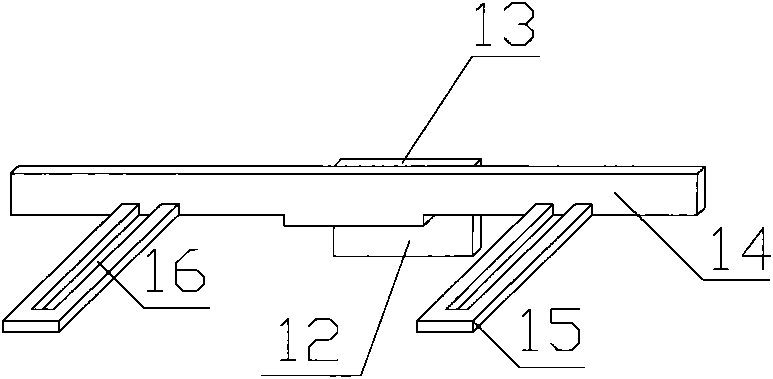

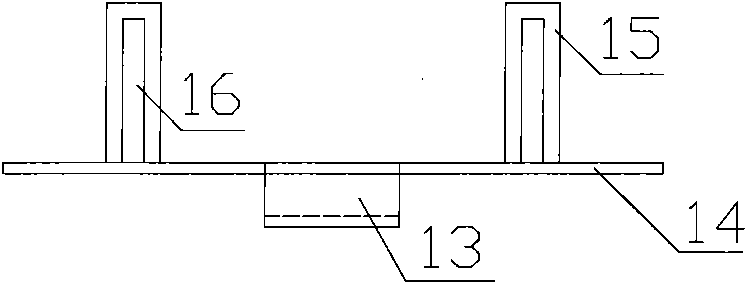

[0038] The present invention is shown in the accompanying drawings, and the present invention is a ribbed prefabricated component formwork for construction. The ribbed prefabricated component formwork for construction includes a module 1 and an end stopper 2. The present invention is characterized in that the end Part block 2 is made up of rib vertical baffle plate 12, rib horizontal baffle plate 13, bottom baffle plate 14, length-adjusting plate 15, length-adjusting hole 16, and wherein length-adjusting hole is arranged on the length-adjusting plate. When assembling the ribbed prefabricated component template, the end block 2 is placed on the end of the module 1. Since the rib horizontal baffle 13 is flush with the bottom plate 4 of the module 1, within the distance of the rib horizontal baffle 13, an end block is formed. rib notch.

[0039] figure 1 , figure 2 Shown, 12 is the vertical baffle plate of rib, and 13 is the horizontal baffle plate of rib, and 14 is the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com