Phosphoric acid and spinel combined high aluminia pouring material

A high-aluminum castable and castable technology, which is applied in the field of refractory materials, can solve the problems of reduced refractoriness, low strength, pouring construction, demoulding, baking and other technical difficulties of castables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

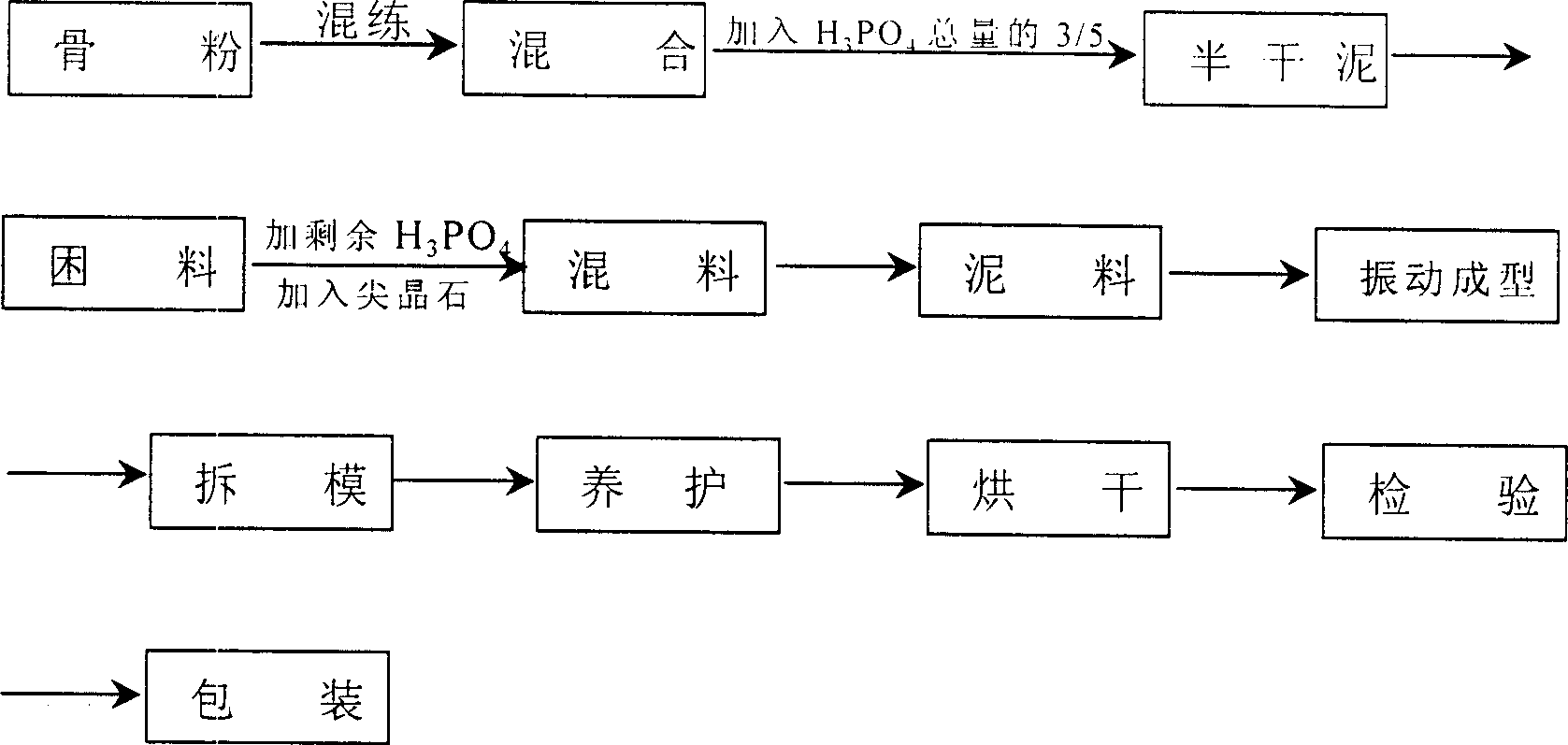

[0018] according to figure 1 As shown, take special grade alumina: 3-5mm coarse particles 27.5%, 2-3mm medium particles 27.5%, 0-2mm fine particles 27%, <0.088mm fine powder 6%, <0.088mm alkaline fused spinel 12%. Phosphoric acid was added with an additional 14% of the total weight added. The samples were prepared by vibrating on a vibrating table. The samples were demolded one day after molding, and then naturally cured for two days, that is to say, the natural curing time after taking the mold and demoulding was three days in total. After drying at 110°C, drying at 450°C, calcining at 1300°C for 3 hours, and calcining at 1450°C for 3 hours, the finished product is obtained after cutting and grinding. The main performance index of the product obtained is as follows:

[0019] Bulk density (g / cm 3 )(dried at 110°C) 2.89

[0020] Strength after three days of natural curing (MPa) Flexural 7.8

[0021] Compression 32.5

[0022] 110℃×24h post-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com