Geometrical shape concrete formwork sealing device

A technology of concrete formwork and sealing device, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc. Structural honeycomb pitting and other problems, to meet the requirements of construction specifications and design requirements, good appearance, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

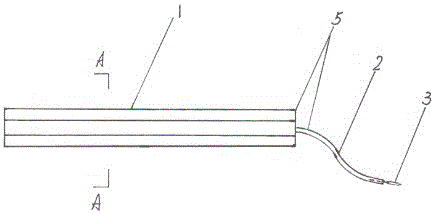

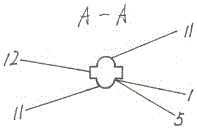

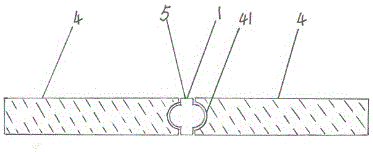

[0011] The invention is attached figure 1 , 2 , 3, the sealing device 5 includes a strip airbag 1, an air delivery tube 2 and an inflatable nozzle 3, one end of the air delivery tube 2 is bonded to one end of the strip airbag 1, and the other end of the air delivery tube 2 is socket-connected with the inflatable nozzle 3; The strip-shaped airbag is flexible, and its section is composed of two semicircular arcs 11 and a rectangle 12, and the two semicircular arcs 11 are symmetrical about the rectangle 12; One end of the shaped airbag 1 is bonded and communicated; the inflatable nozzle 3 connected to the other end of the air pipe 2 is a ball needle type one-way inflatable nozzle, which only takes in air and does not return air, so as to facilitate inflation.

[0012] The sealing principle and method of use of the present invention: the sealing device 5 is specially designed for wooden formwork, a formwork sealing device used for vertical joints when pouring concrete, firstly op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com