Building template

A construction and formwork technology that is used in construction, building construction, formwork/formwork components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

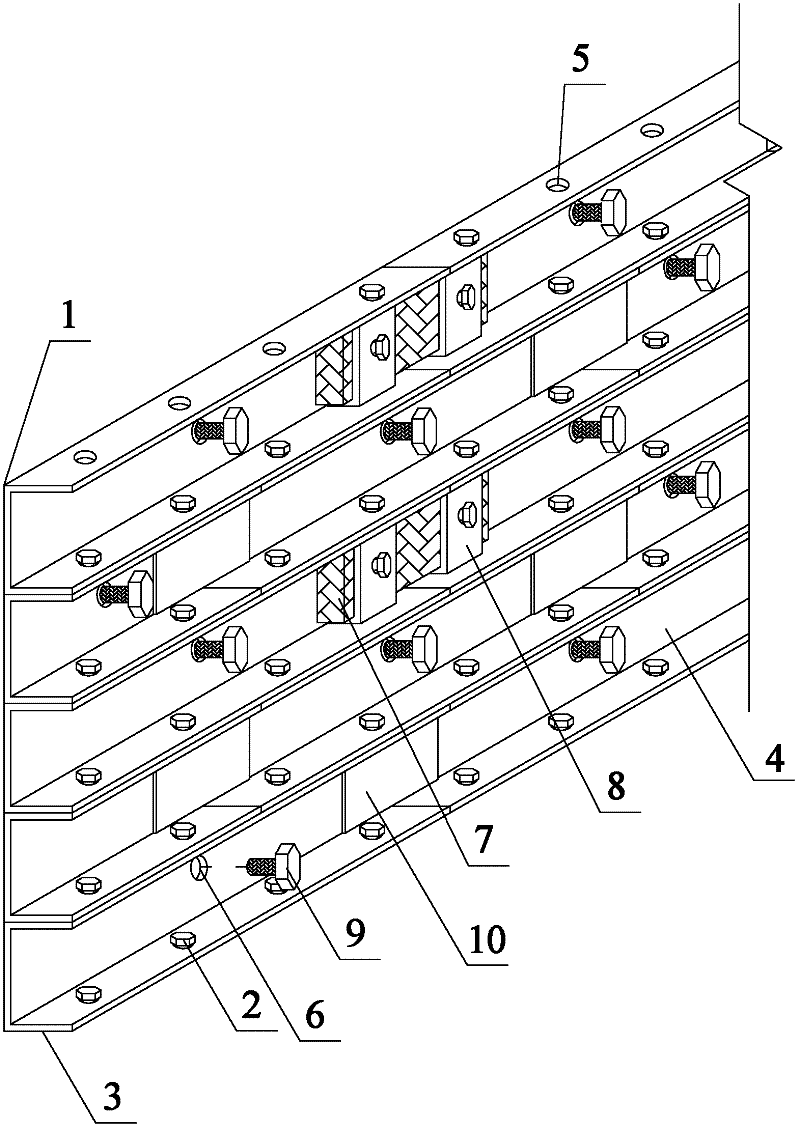

[0032] The invention is attached Figure 1-20 As shown, a formwork for construction, the formwork for construction includes a slot-shaped module 1, bolts 2 or bolts. The present invention is characterized in that the formwork for construction has an anti-leakage slurry mold cover 10 at the longitudinal joint of the groove-shaped modules 1 . The trough-shaped module 1 is composed of a web 4 and a flange 3. When assembling the formwork, the leakage-proof slurry mold cover 10 is inserted into the 4 end webs of the trough-shaped module 1, and the trough-shaped modules 1 are arranged neatly , the bolts 2 or pins pass through the holes 5 on the flanges 3 of the trough-shaped modules 1 to connect two adjacent trough-shaped modules 1 to form an integral building formwork. Such as figure 1 shown.

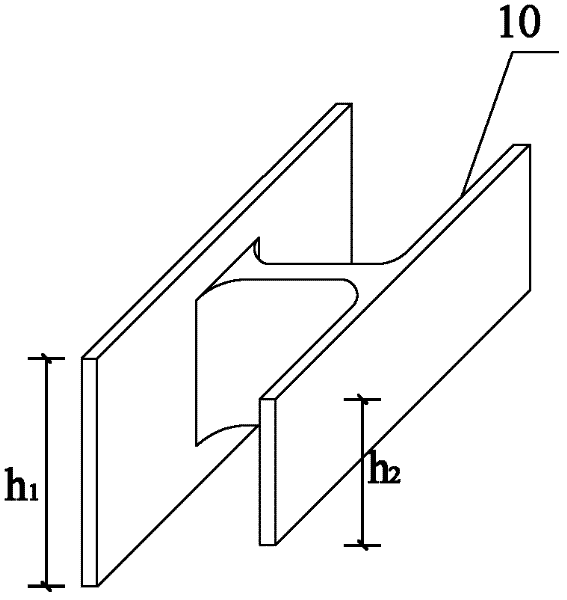

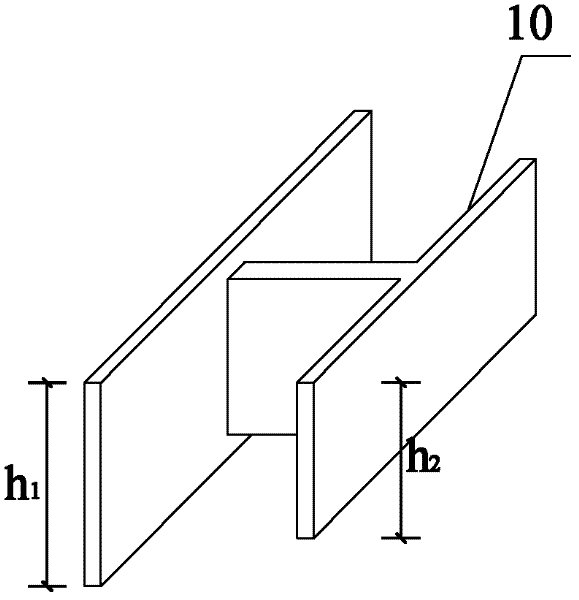

[0033] The present invention is also characterized in that the leak-proof slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com