Washroom water-proof structure and construction method

A technology of waterproof structure and construction method, which is applied in building components, building structure, formwork/formwork/work frame, etc., can solve the difficult construction of masonry anti-sill, easily damaged structural floor, and poor waterproof effect of masonry anti-sill. good question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

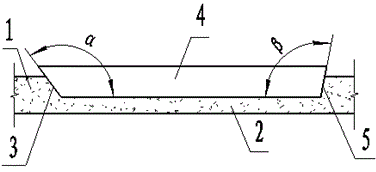

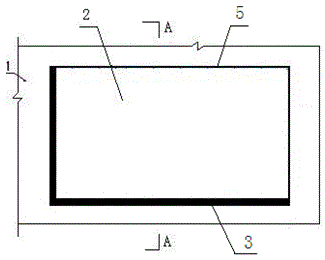

[0019] A toilet waterproof structure of the present invention comprises a structural floor 1 and a toilet descending plate 2. When the toilet descending plate 2 is made on the structural floor 1, the surroundings of the toilet descending plate 2 are made into slopes, and the slopes include folded plate slopes 3 and close to The micro slope 5 of the structural wall 9 is provided with a masonry reverse sill 8 on the folded plate slope 3 , and the structural wall 9 is poured on the edge of the micro slope 5 . The inclination angle of the folded plate slope 3 is 45°, and the inclination angle of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com