beam formwork for building

A beam formwork and construction technology, applied in construction, building structure, formwork/formwork/work frame, etc., can solve the problems of forest resource consumption, weak rigidity, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

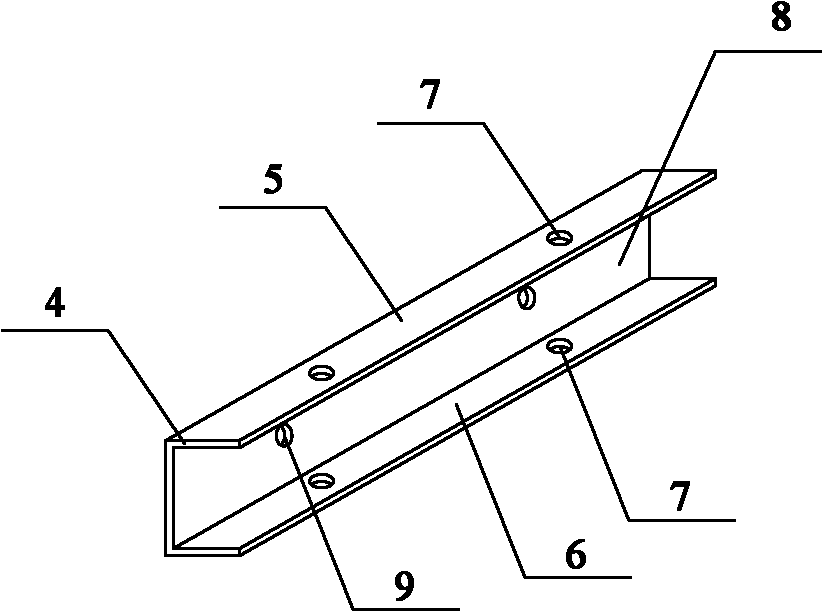

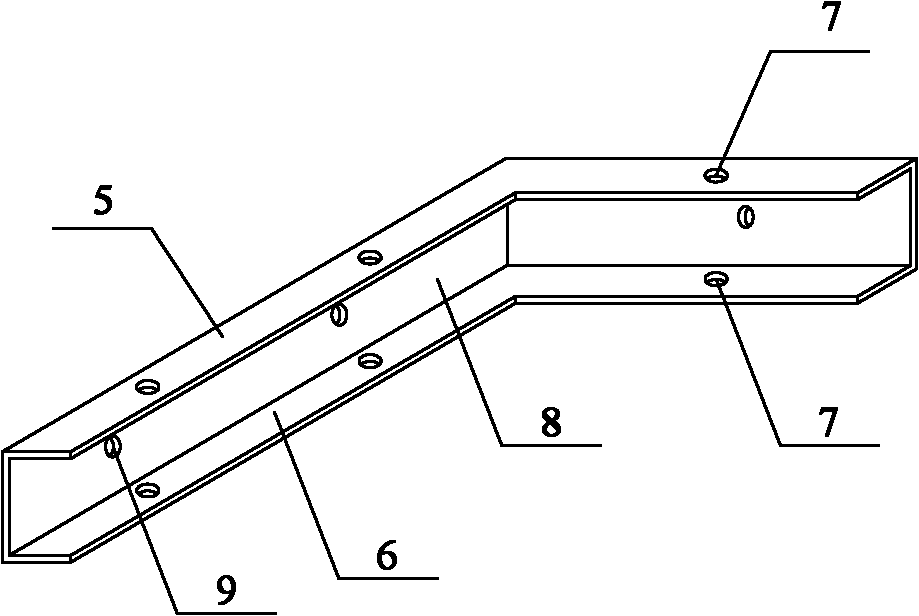

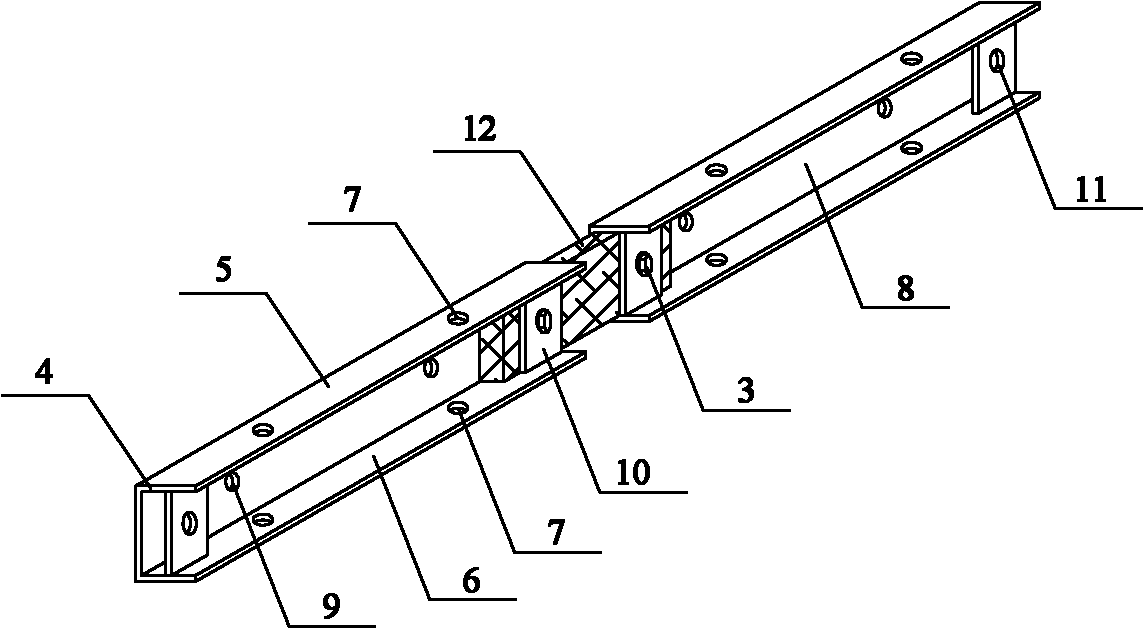

[0020] As shown in the accompanying drawings, a beam formwork for construction includes a bottom formwork 1 and a side formwork 2. The bottom formwork 1 and the side formwork 2 are composed of two or more groove-shaped modules 4 connected to each other through bolts 3 or bolts. Or threaded buckle assembly. The present invention is characterized in that the trough modules 4 are longitudinally connected by connecting bars 12 , the ends of the trough modules 4 have connecting bar locators 10 , and the connecting bars 12 are located between the side plates 8 of the trough modules 4 and the connecting bar locators 10 .

[0021] The present invention is also characterized in that there is a hole 11 on the connecting strip positioning piece 10 at the end of the slot module 4 .

[0022] The present invention is also characterized in that there are holes 7 on the top plate 5 and bottom plate 6 of the trough module 4 , and holes 9 are formed on the side plates 8 .

[0023] figure 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com