Cast in situ concrete tool type steel frame wood plastic template system and construction method thereof

A wood-plastic formwork and tool-type technology, which is applied in the fields of formwork/formwork components, on-site preparation of building components, and formwork processing, etc., can solve the problems of increasing formwork loss rate, low production efficiency, labor and labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Each component of the present invention will be described in detail below in conjunction with the accompanying drawings. The tool-type steel-frame wood-plastic formwork system and its construction technology for cast-in-place concrete in the present invention refer to the tool-type steel-frame wood-plastic formwork system and its construction technology for cast-in-place concrete structures.

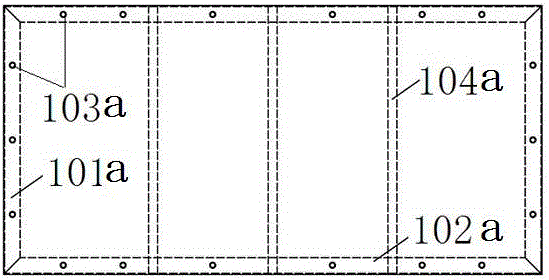

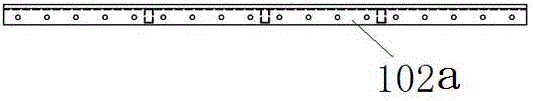

[0083] Tool type steel frame wood-plastic template as attached Figure 1 to Figure 10 As shown in the accompanying drawings, each mark in the tool-type steel frame wood-plastic formwork is: 101a: short outer frame; 102a: long outer frame; 103a: connection hole of the fixed-length formwork; 104a: back flute of the fixed-length formwork; 201a: short frame ;202a: long frame; 203a: U-shaped bracket; 204a: back corrugated of variable-scale formwork; 2021a: connecting surface of long frame and variable-scale wood-plastic panel; 2022a: connecting part of long frame and short frame; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com