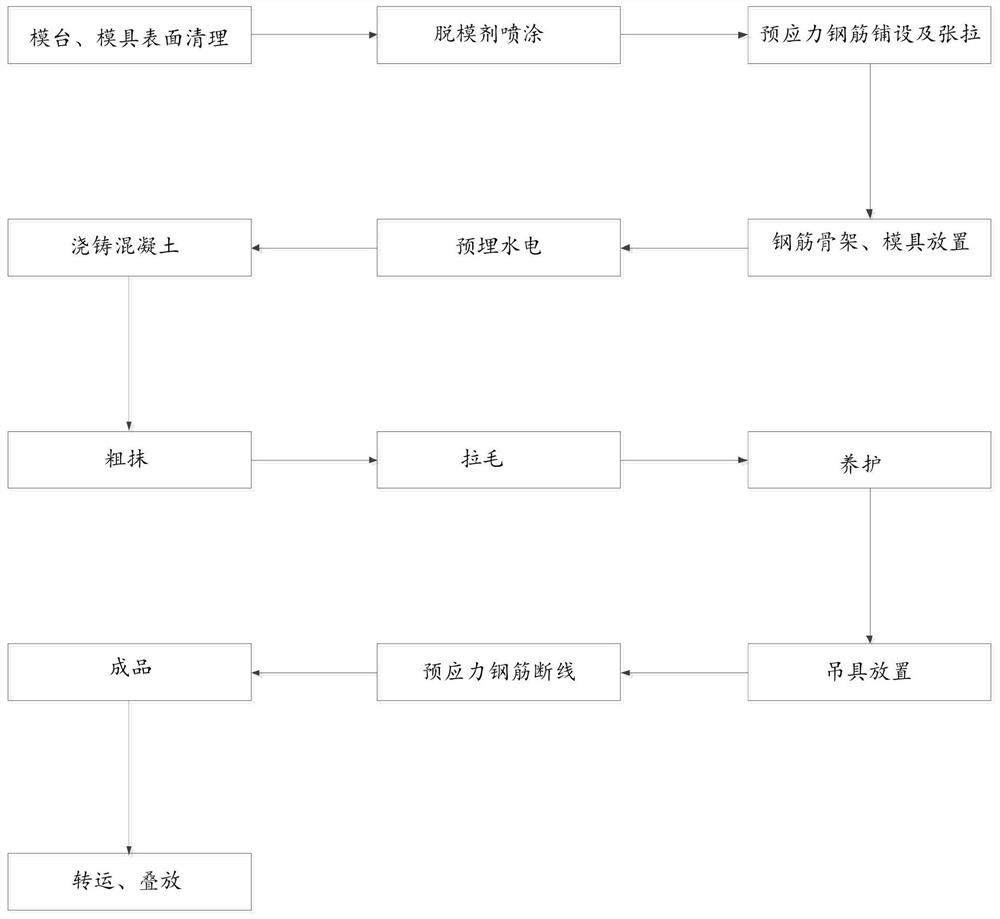

Production process of prestressed concrete laminated slab bottom plates

A production process and concrete technology, which is applied in the production process field of prestressed concrete laminated slab floor, can solve the problems of slab surface warping, fracture, and increasing the number of stacked layers, so as to reduce the number of supports, avoid slab surface warping and fracture, The effect of reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

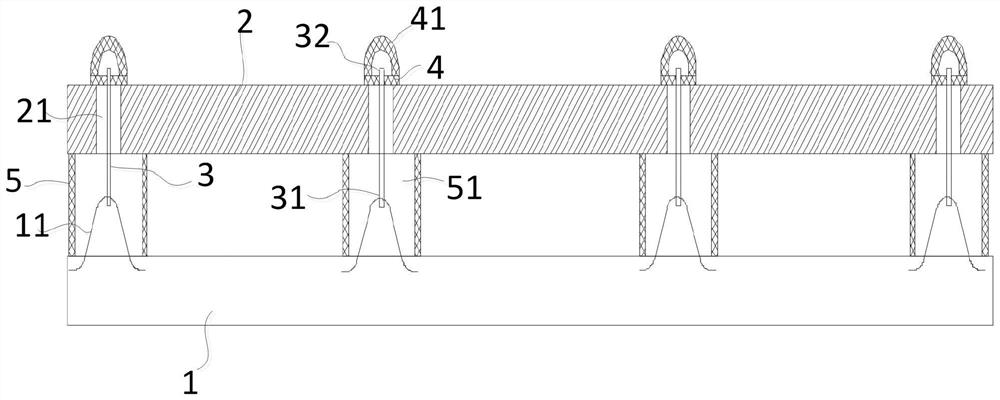

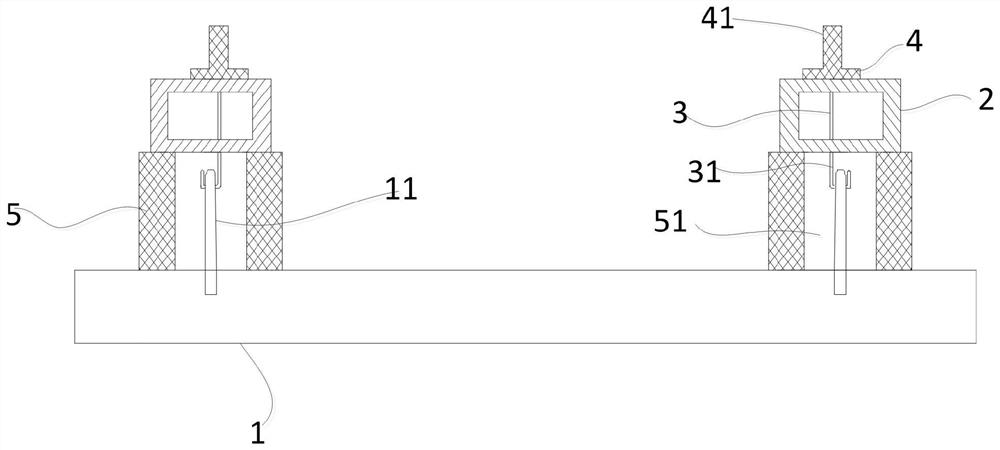

[0034] Example 1, such as figure 1 , figure 2 As shown, the purpose of this embodiment is to provide a prestressed concrete laminated slab production process to solve the problem of warping of the laminated slab surface caused by the production process of the laminated slab base.

[0035] The production process of the prestressed concrete laminated slab floor provided in this embodiment includes the following steps:

[0036] First, clean the surface of the mold table and the mold to ensure that the mold table and the surface of the mold are clean. Since the later use of the laminated slab bottom plate needs to be directly painted on the bottom, it is necessary to ensure that the mold table and the surface of the mold are clean to ensure that there is no concrete residue. .

[0037] After the mold table and the mold are cleaned, apply the release agent on the surface of the mold table and use a scraper to smooth the release agent to ensure the uniformity and thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com