Hot air main pipe refractory masonry mold and its construction method

A hot blast main pipe and construction method technology, applied in the direction of furnace, furnace type, blast furnace parts, etc., can solve the problems of long masonry time in the pipe, large construction accuracy error, large masonry ash gap, etc., and achieve convenient branching and dismantling, Guaranteeing quality and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

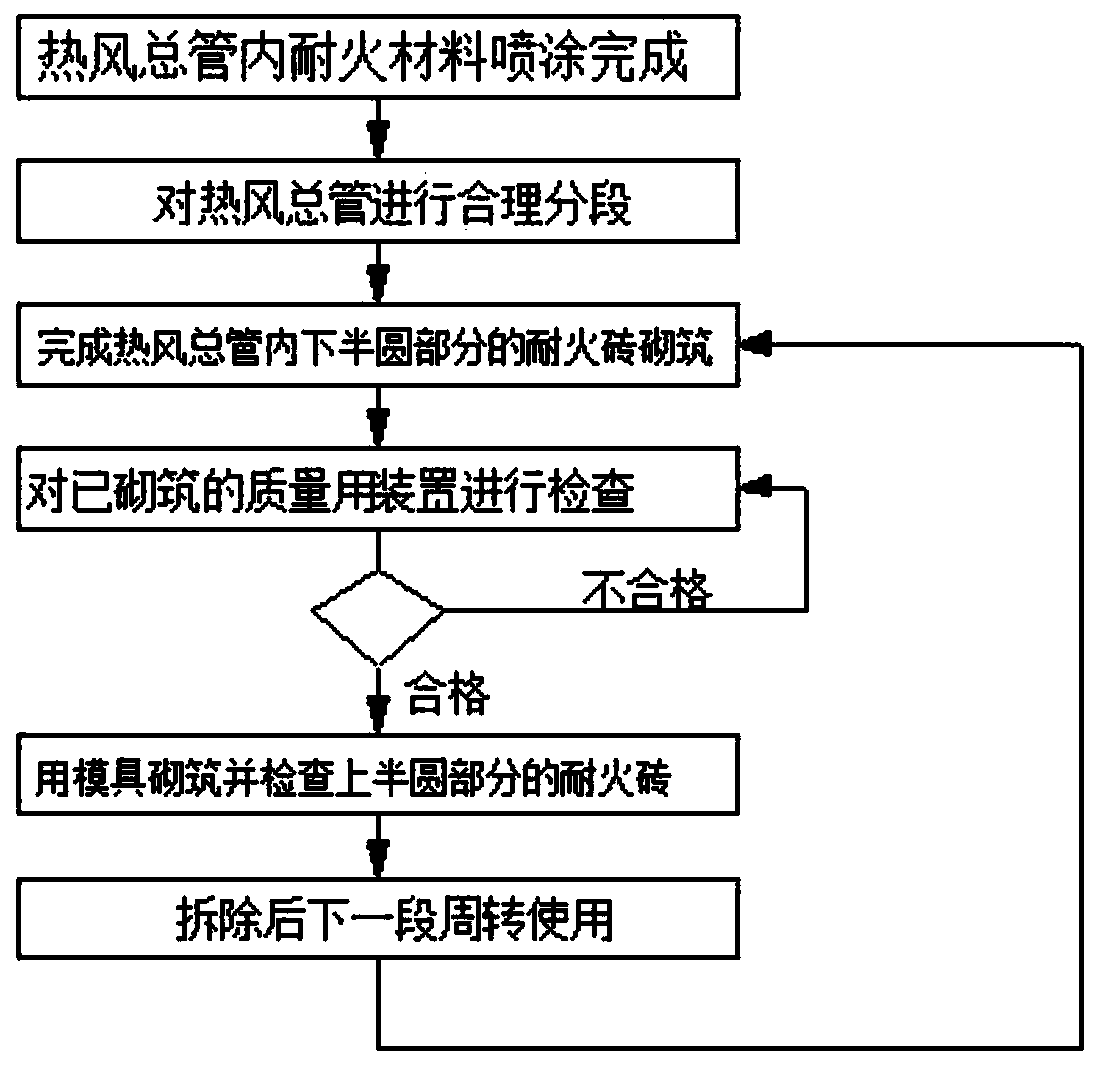

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

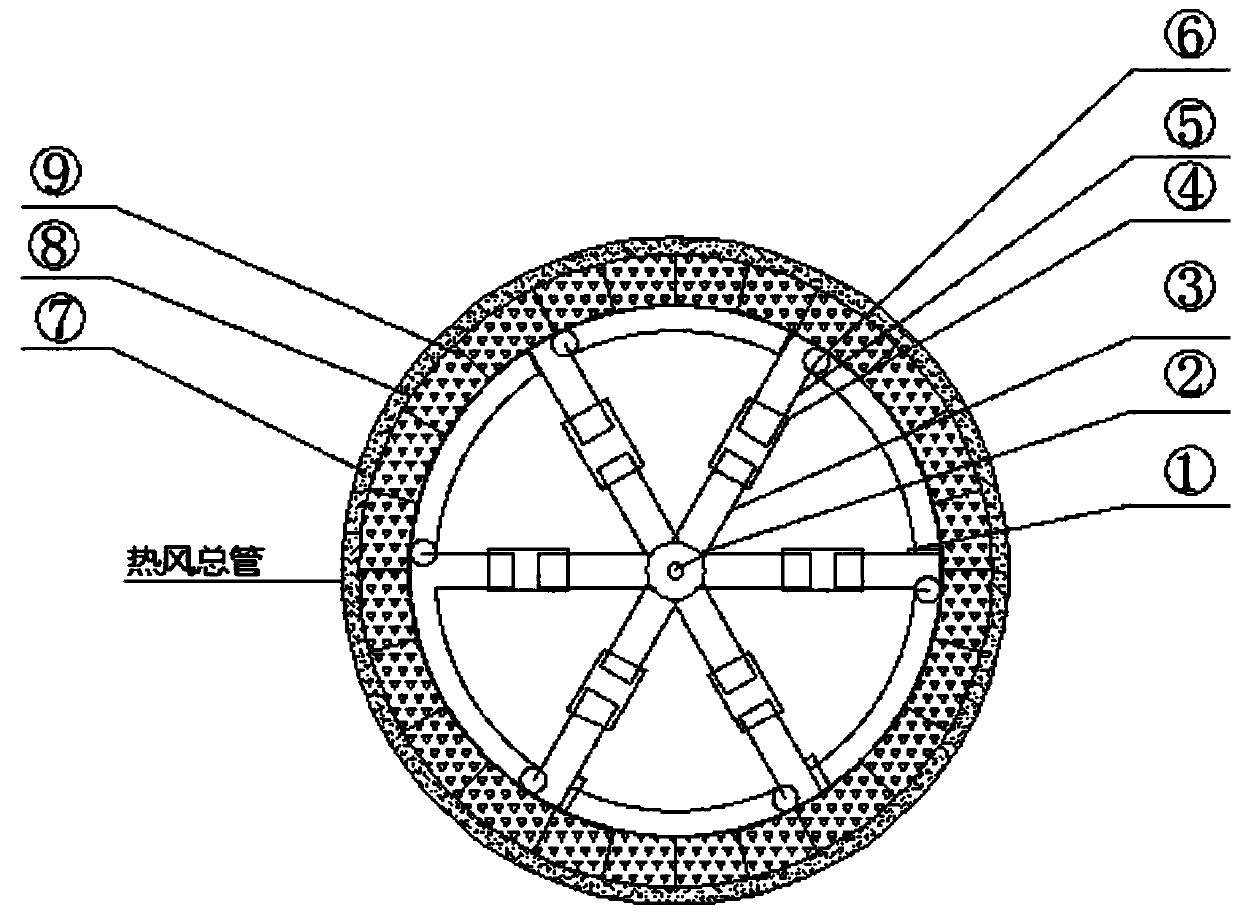

[0032] Such as figure 1 As shown, a hot air main pipe refractory masonry mold includes a central shaft 2 and three rotatable support rods arranged on the central shaft 2 in the middle. The support rods can be stretched on both sides of the central shaft 2. All are hinged with one end of the arc arm 6 and are provided with a docking slot 1. All the arc arms 6 are arranged in the same direction around the central axis 2 and are of equal length. The slots 1 are mated and connected, and all the arc arms 6 and the docking slots 1 are mated and connected to form the inner circle of the refractory brick 8 required by the design.

[0033] Such as figure 1 As shown, in this embodiment, the support rod is fixed rod 3, adjusting rod 4 and moving rod 5 connected in sequence from the central axis 2 to both sides, and the fixed rod 3 and the moving rod 5 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com