Beam column integral prefabricated joint with rigid template support at connecting position and construction method of beam column integral prefabricated joint

An integral prefabrication and joint technology, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of poor integrity of concrete frame structure, difficult control of weld quality, safety and quality, etc. , to achieve the effect of easy control of construction quality, convenient construction process and reduction of the number of supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

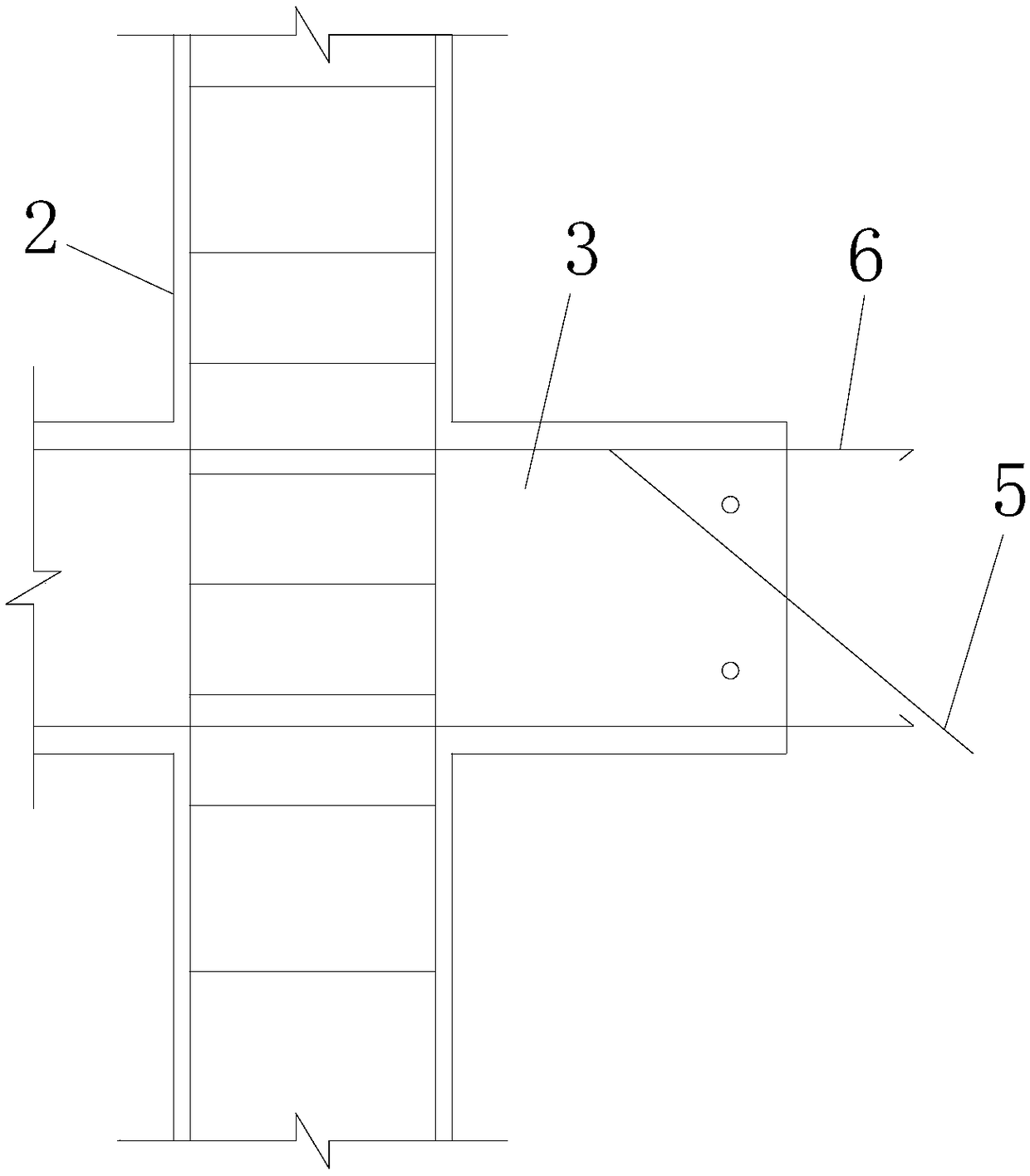

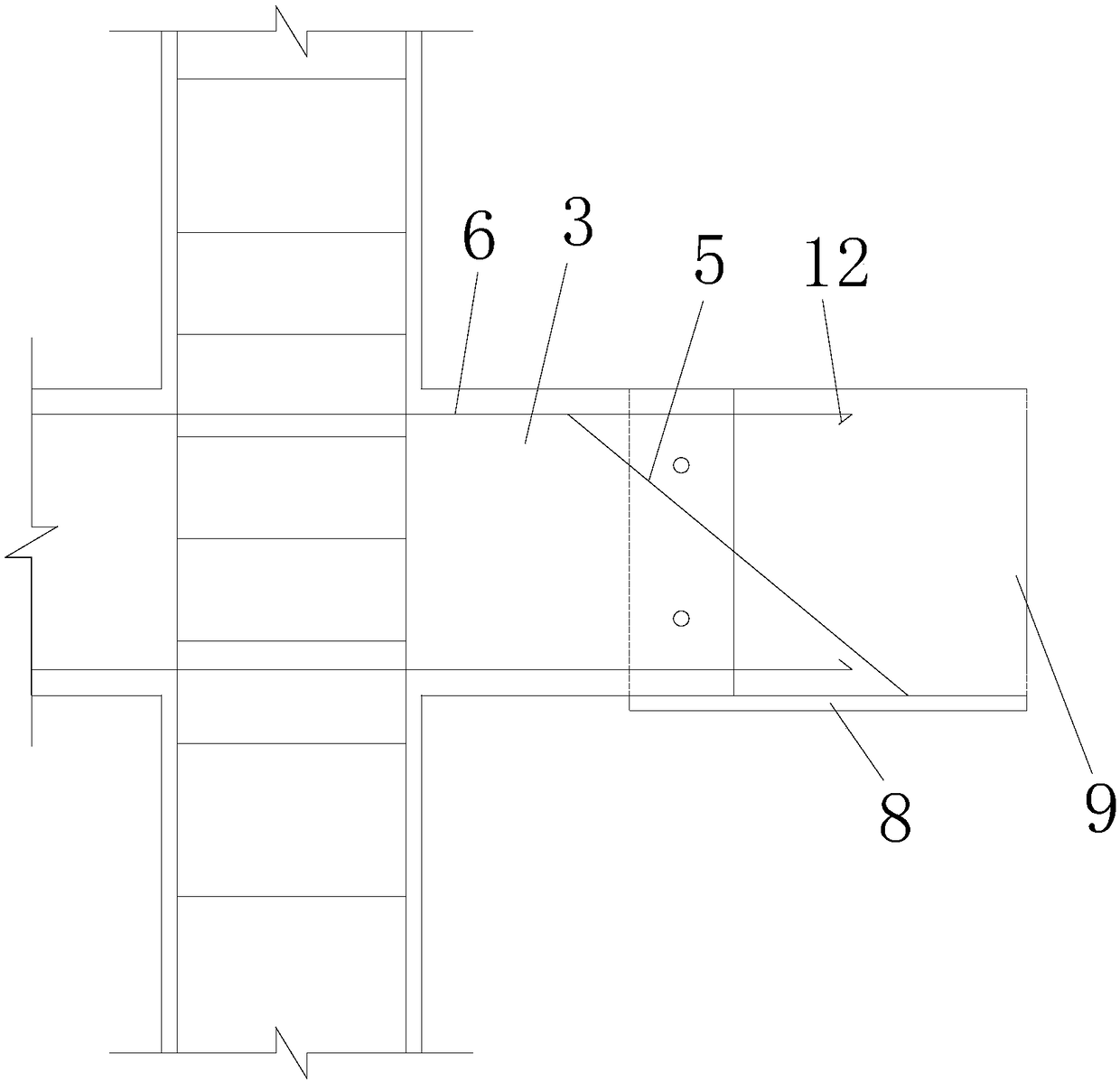

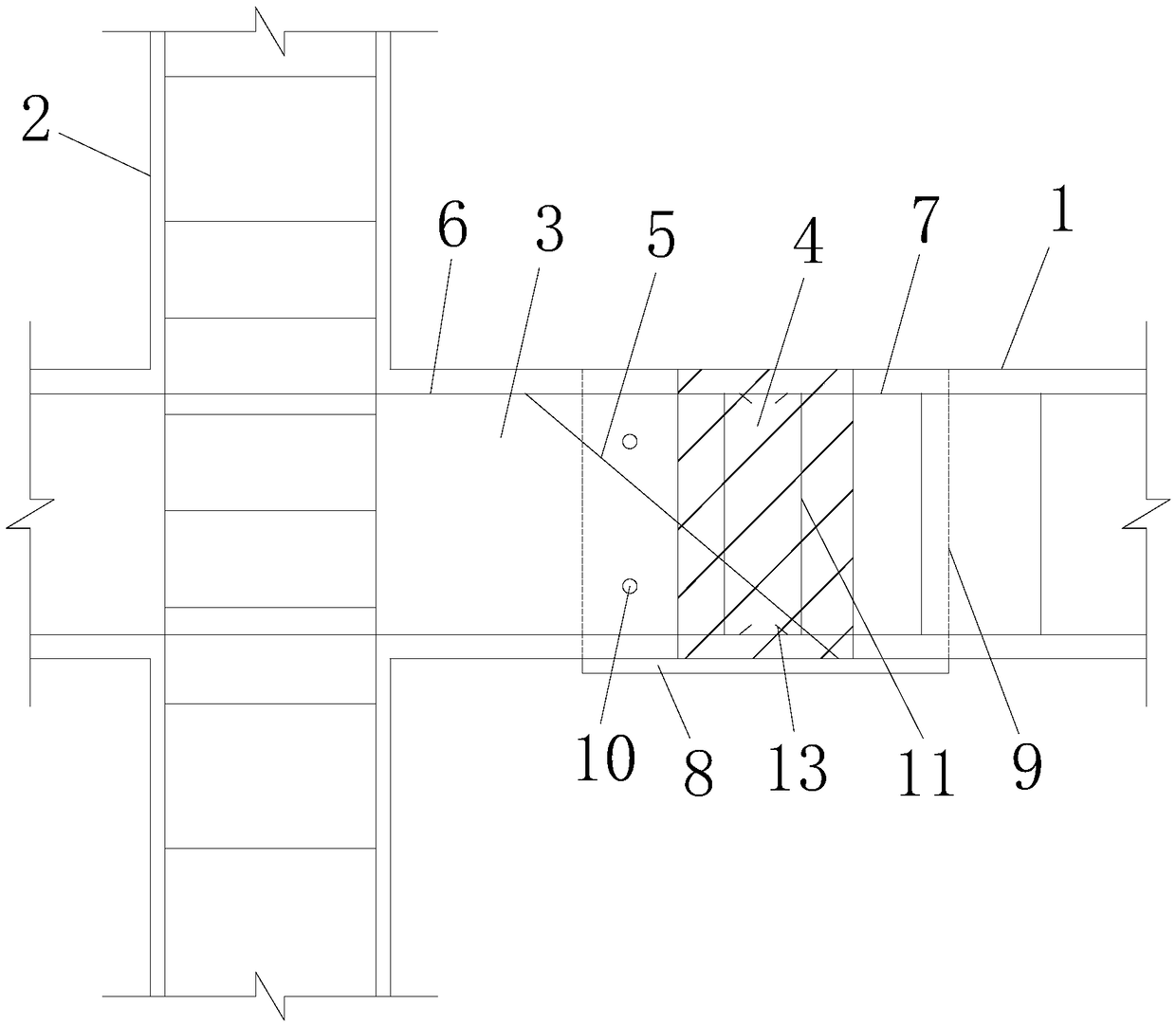

[0036] A beam-column integral prefabricated joint with rigid formwork support at the joint, including a beam 1, a steel formwork, and a prefabricated column 2 with a prefabricated joint. The prefabricated joint has a butt joint 3 that is docked with the cross beam 1, and the steel formwork and the joint 3 Fixed connection, the beam 1 is connected to the steel formwork, the steel formwork, the butt section 3 and the beam 1 are fixedly connected by pouring the connection section 4, and the butt section 3 has mitered reinforcement bars 5 and column connection reinforcement bars 6, and the mitered reinforcement bars 5 and the column connecting steel bar 6 all extend into the pouring connecting section 4, the protruding end of the mitred reinforcing bar 5 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com