Workshop structure for position above generator layer of underground powerhouse of hydropower station

A technology for underground powerhouses and generators, which is applied to underwater structures, hydropower, hydropower stations, etc. It can solve the problems of difficult vibration, cracking of the beam body, and high excavation requirements, so as to reduce the workload of excavation , Improve the construction speed and the effect of increasing the excavation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

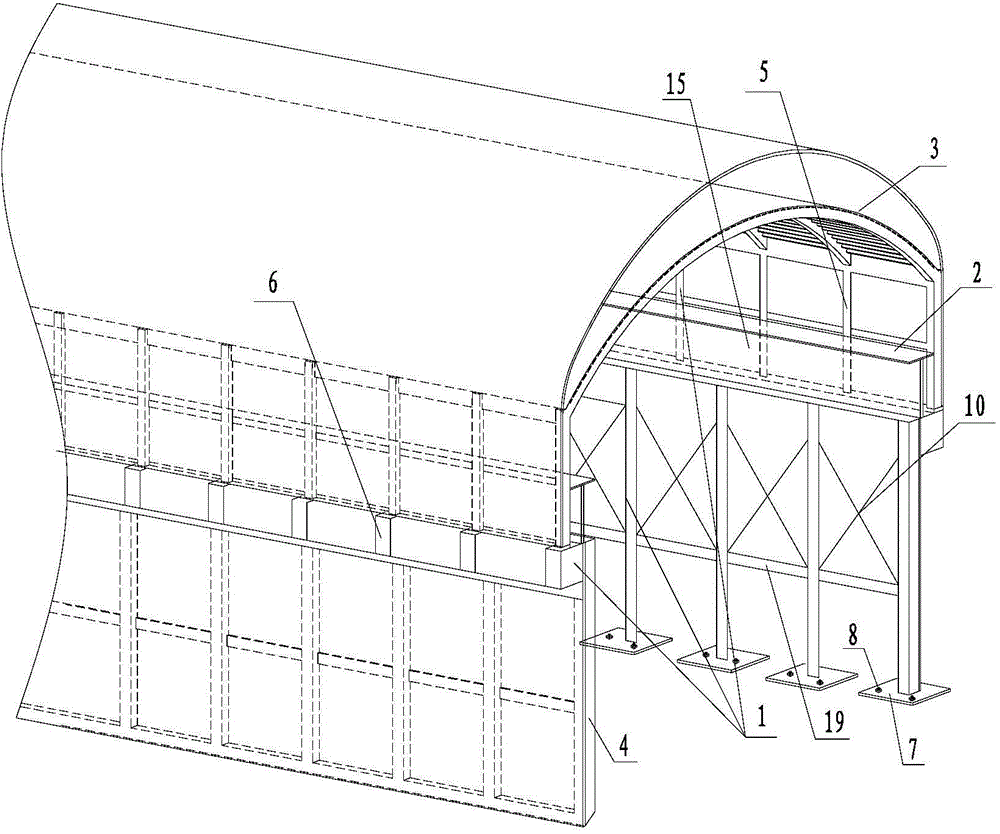

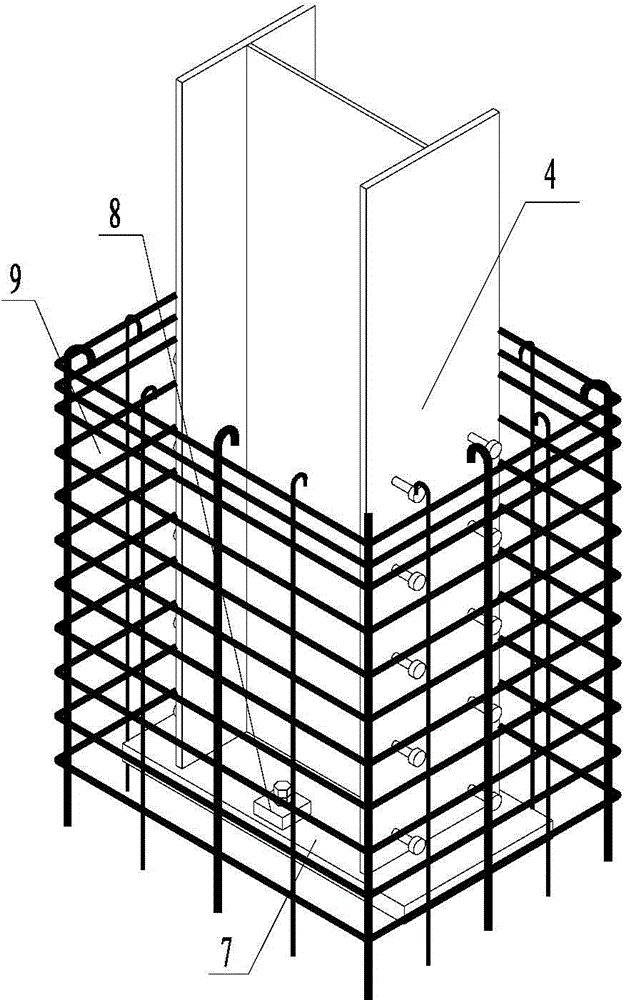

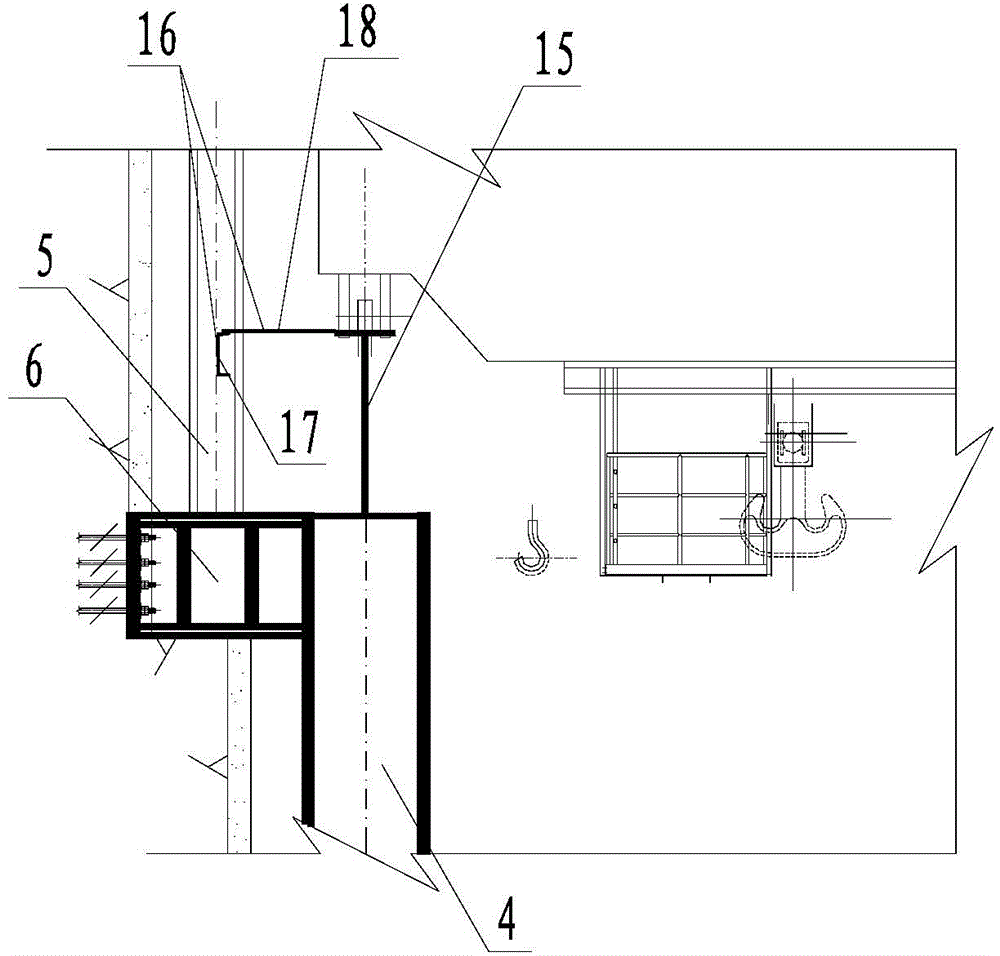

[0022] like figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 Shown is a powerhouse structure above the generator floor of the underground powerhouse of a hydropower station, which is less difficult to excavate and has less interference with other construction work in the construction process provided by the present invention. The plant structure includes a steel skeleton system 1, a rail system 2 and a protection system 3, the rail system 2 is fixedly installed on the middle and upper part of the steel skeleton system 1, and the protection system 3 is covered and connected to the The outer side of the steel frame system 1, the plant structure is fixedly connected to the external civil foundation through the steel frame system 1. Since the plant structure provided by this application is directly installed on the previously arranged foundation after the excavation of the underground cavern is completed, the construction of the plant structure described in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com