Front-supporting and rear-pulling type foundation pit support system and construction method thereof

A foundation pit enclosure and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of affecting the excavation efficiency at the pit side and large deformation of the enclosure system, so as to improve construction safety and reduce Effect of Difficulty of Excavation, Improvement of Reliability and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

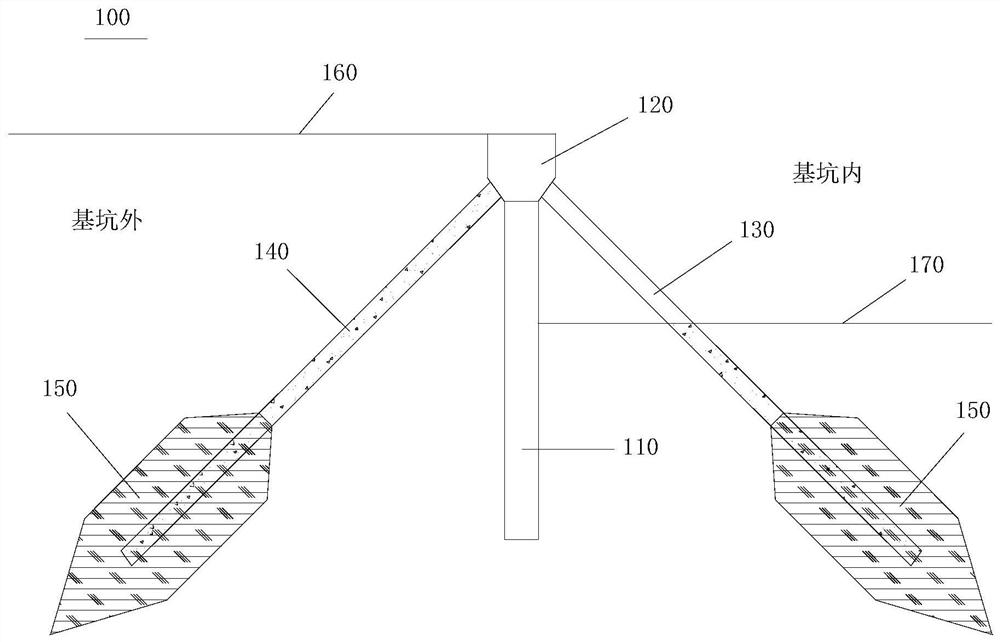

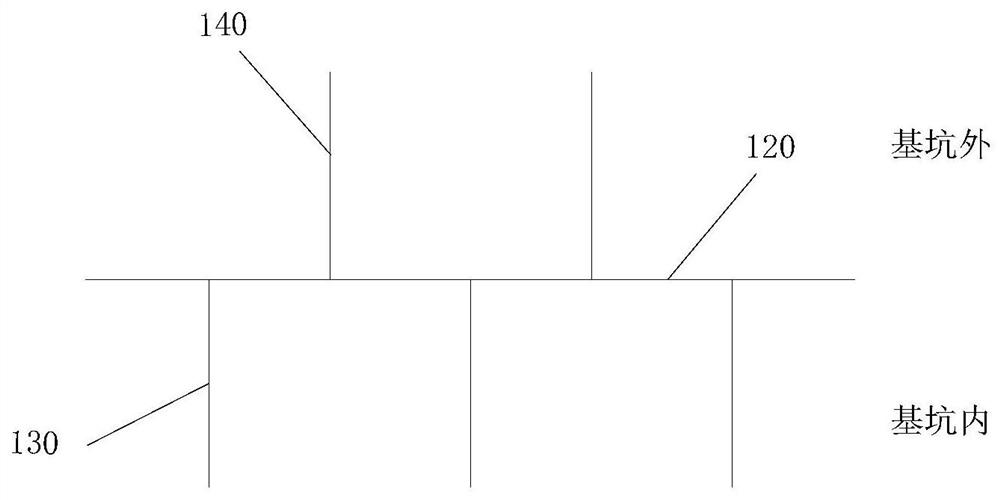

[0040] The present invention will be described in detail below with reference to the accompanying drawings: The advantages and features of the present invention will be more clearly understood from the following description. It should be noted that, the accompanying drawings are all in a very simplified form and in inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

[0041] Please refer to Figure 1 to Figure 2 , the embodiment of the present invention provides a front support and back pull type foundation pit enclosure system 100, which may include:

[0042] The enclosure piles 110 are constructed vertically in the soil to form foundation pit enclosures; the enclosure piles 110 include but are not limited to bored cast-in-place piles or water-stop steel pipe piles, and can also be other pile structures known in the art .

[0043] The capping beam 120 is arranged on the enclosure pile 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com