Top-rigid-and-bottom-flexible deep foundation pit supporting system and construction method thereof

A deep foundation pit support and system technology, applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of inconvenient fully rigid support structure, slow construction progress, material waste cost, etc., to reduce the difficulty of earthwork excavation , saving construction period and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

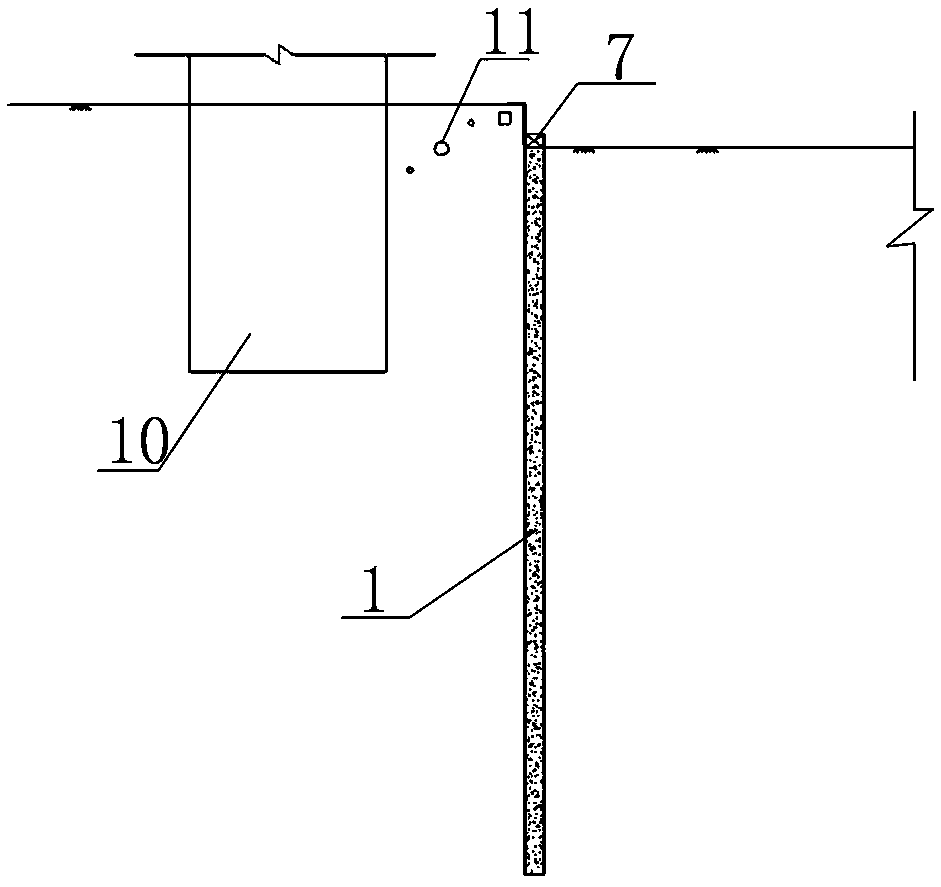

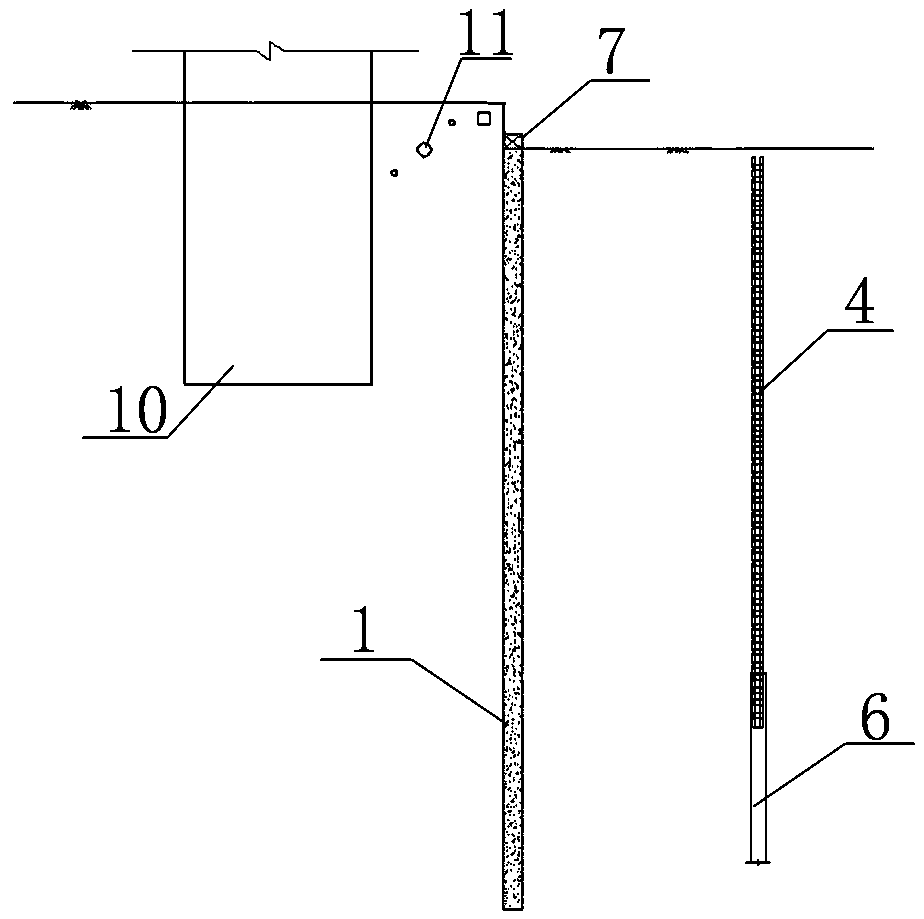

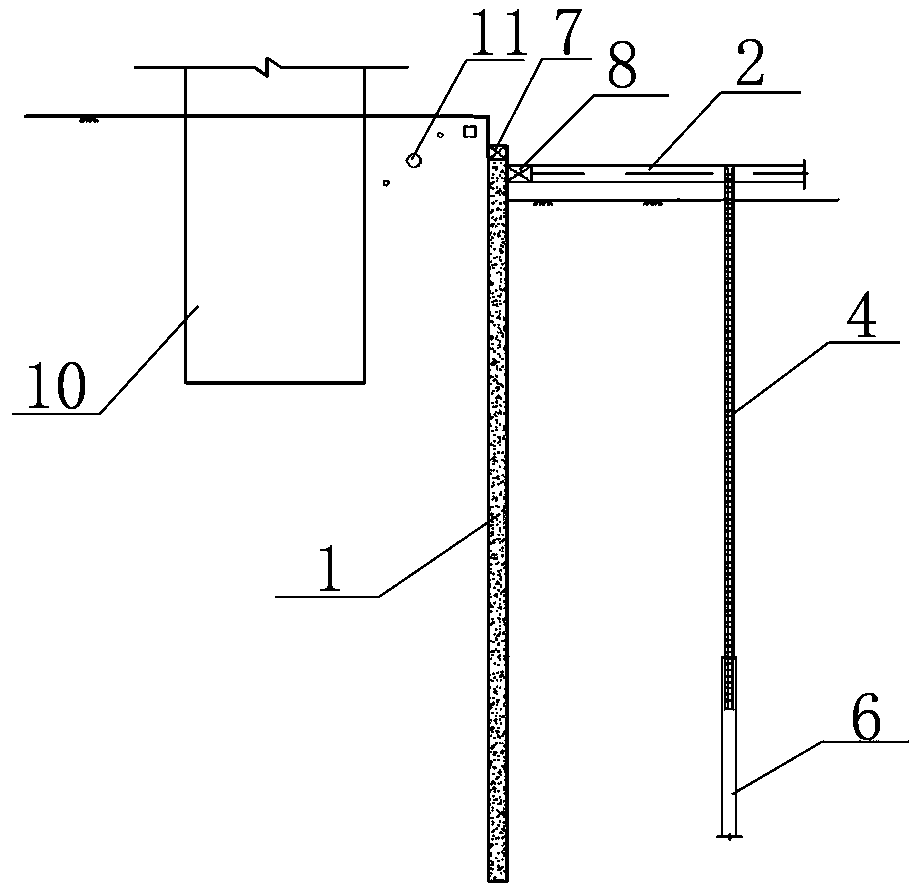

[0039] In this embodiment, the deep foundation pit support system with rigid upper and lower soft is used in the basement of the existing building 10 beside the foundation pit, and various pipelines 11 are buried in the foundation, subway tunnel, entrance and exit, and underground.

[0040] like Figure 1-7 As shown in the figure, this deep foundation pit support system with rigid upper and lower softness includes vertical support members 1 arranged along the edge of the foundation pit 5, rigid support members 2 supported on the upper part of the vertical support member 1, and pull The flexible anchor member 3 is arranged at the lower part of the vertical support member 1; the rigid support member 2 has at least two rows, which are arranged at intervals in the vertical direction; wherein, the rigid support members 2 of each row are arranged vertically and horizontally in the same horizontal plane; The flexible anchor members 3 have at least two rows, which are arranged in a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com