Pushing device of self-compaction reinforcing and anti-seepage pilot pipe and use method thereof

A pilot tube, self-compacting technology, applied in the direction of pipes/pipe joints/fittings, pipe laying and maintenance, mechanical equipment, etc., can solve the problem of no precipitation, and achieve the effect of reducing permeability, ensuring stability and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

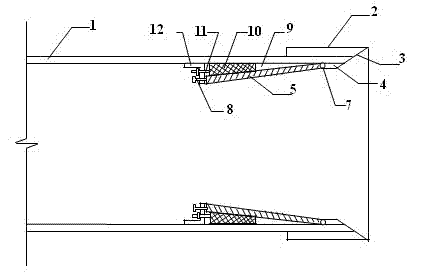

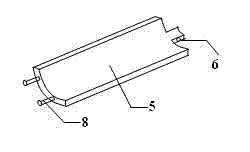

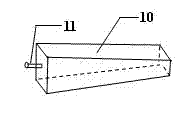

[0024] Example 1 see Figure 1 to Figure 6 , the self-compacting anti-seepage pilot tube jacking device of the present invention, along the inner side of the front end of the pilot tube 1, a compacting plate 5 is arranged in the full circumferential direction or partially, the front end of the compacting plate 5 has a rotating shaft hole 6, and the rotating shaft 7 passes through the rotating shaft hole 6 is connected to the rotating shaft support 4 at the cutting edge 3 of the pilot pipe; the squeeze plate 5 can rotate around the rotating shaft 7 to change the angle between the squeeze plate 5 and the pilot pipe 1, and the rear end of the squeeze plate 5 is limited There is a fixed plate 12 on the pilot tube 1 corresponding to the position of the position bolt 8 and the limit bolt 8, and the fixed plate 12 is welded on the inner wall of the pilot tube 1. Internal movement: There is a wedge-shaped gap 9 between the squeeze plate 5 and the pilot tube 1, and a wedge-shaped rod 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com