Method for drilling anchor rod hole and anchoring anchor rod in broken roof

A technology of broken roof and anchoring method, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the problems of difficult roadway maintenance, large deformation and failure of mine roadways, avoid the problem of anchoring failure, and improve the anchorage of bolts. strength, the effect of increasing the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

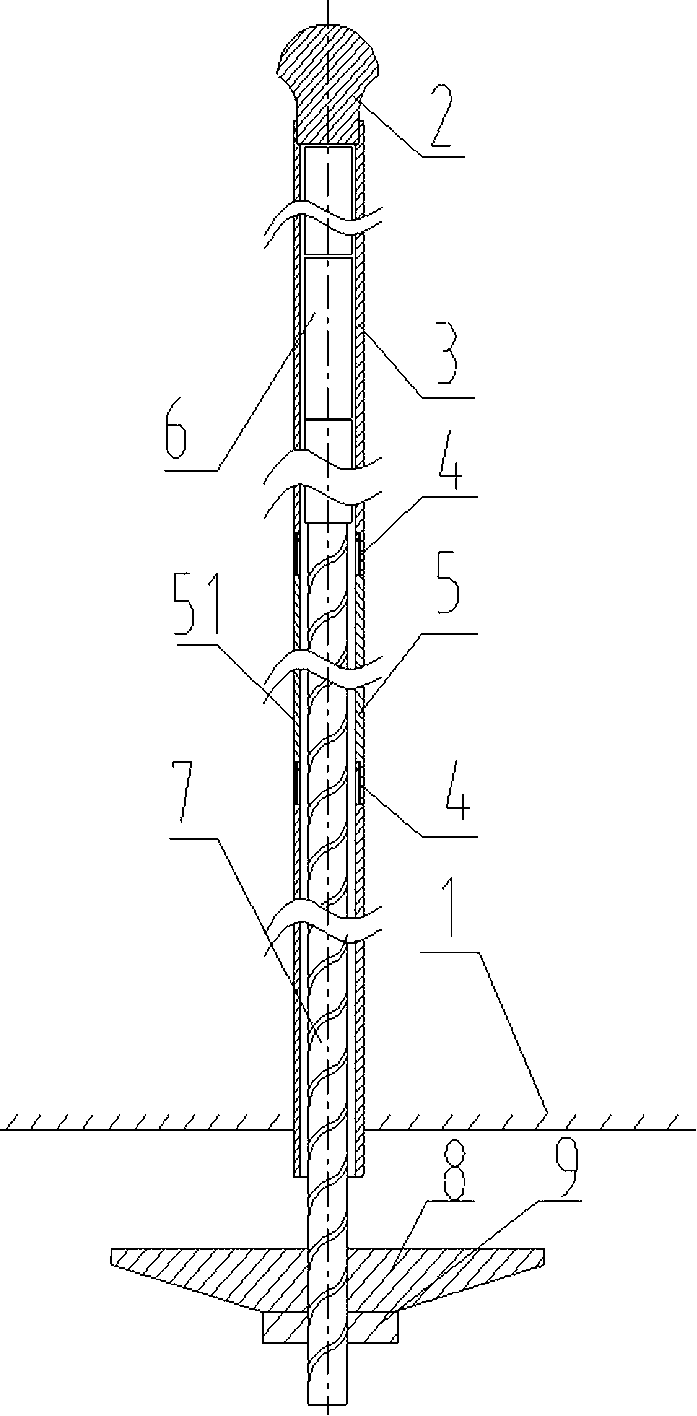

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 Shown, the present invention comprises the steps:

[0014] 1) Assembling the drill pipe: Determine the drilling depth and bolt length according to the bolt support parameters of the broken surrounding rock 1; when the drilling depth is less than the length of one drill pipe 3, two hollow tubular structure drill pipes 3 The threaded ends are connected by connecting sleeve 4; when the drilling depth is greater than the length of a drill rod 3, a connecting rod 5 is connected between the threaded ends of two drilling rods 3 by connecting sleeve 4; the connecting rod 5 It consists of one connecting rod 51, or a plurality of connecting rods 51 connected through the connecting sleeve 4, and the connecting rod 51 is a hollow tubular structure.

[0015] 2) Drilling: Connect one end of the drill pipe 3 square inner buckle with the drill bit 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com