Construction method of karst stratum pile foundation

A construction method and stratum technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high cost and long construction period, and achieve the effects of simple construction, shortened construction period and avoiding hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

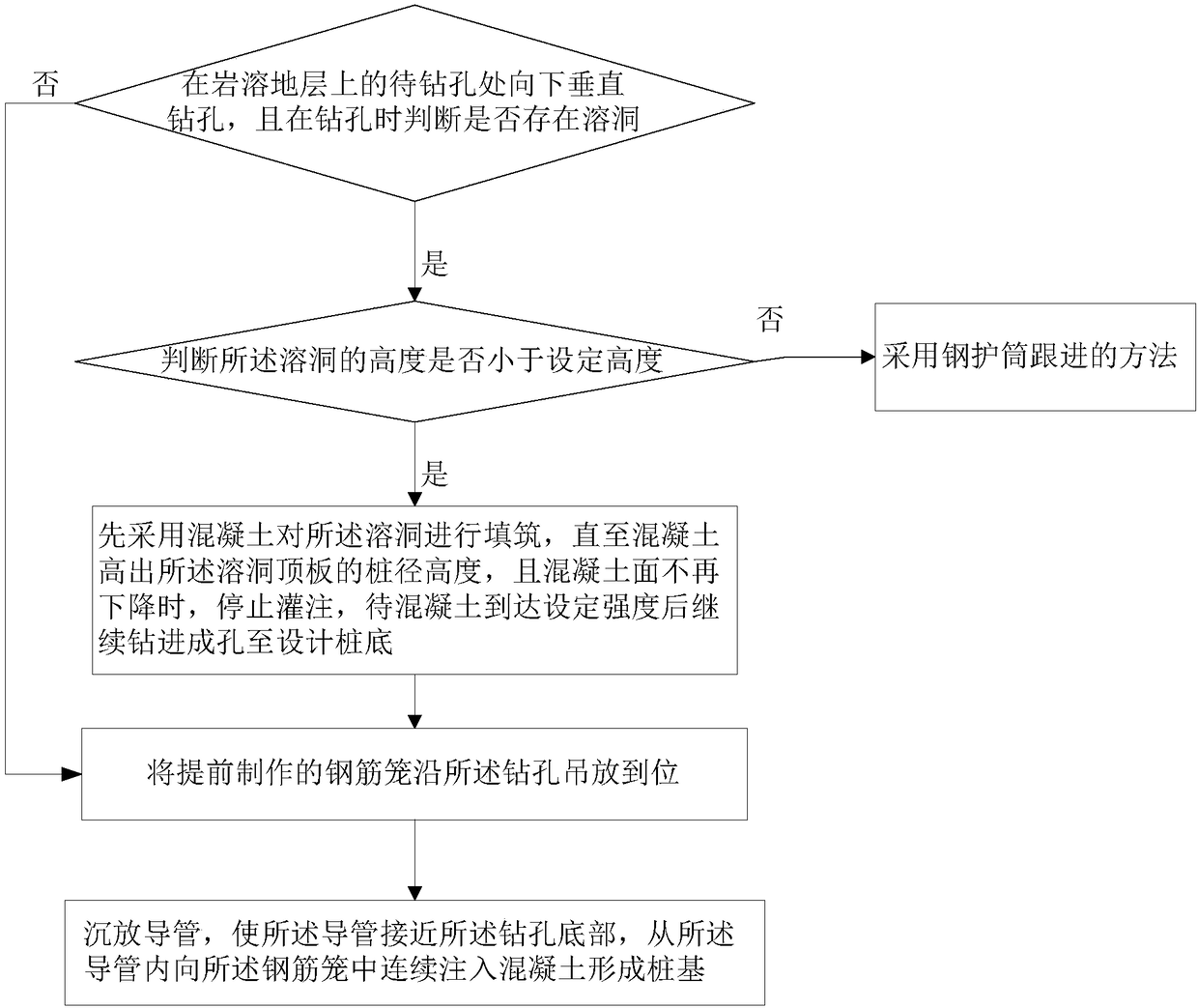

[0020] Such as figure 1 As shown, the present embodiment provides a construction method for pile foundations in karst strata, which includes the following steps: Step S1: Drill vertically downward at the place to be drilled on the karst stratum, and determine whether there is a karst cave when drilling. exists, then enter step S2, otherwise enter step S3; step S2: judge the height of the karst cave, if the height of the karst cave is less than the set height, first use concrete to fill the karst cave until the concrete is higher than the set height When the height of the pile diameter of the roof of the karst cave and the concrete surface no longer drops, stop pouring, and continue drilling into the hole to the bottom of the designed pile after the concrete reaches the set strength; if the height of the karst cave is greater than the set height, use a steel casing The follow-up method; step S3: hoisting the pre-fabricated reinforcement cage into place along the borehole; step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com