Rotary drilling dry-excavation method for cast-in-situ bored piles of viaduct bridges by adopting double steel protection canisters

A technology of bored piles and steel casings, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of inability to meet standards in safe and civilized construction, inability to use the mud circulation method, and poor pile quality. The effect of safe and civilized construction, shortening pile formation time and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

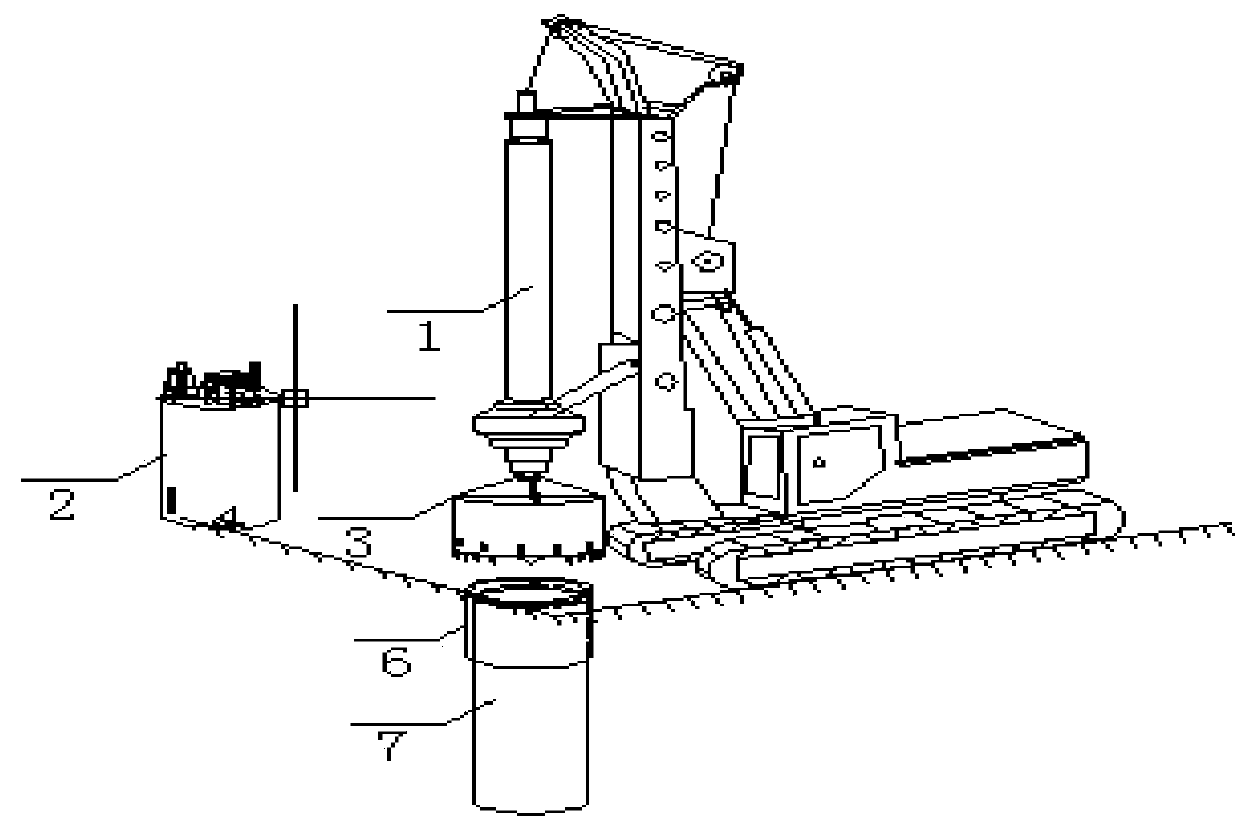

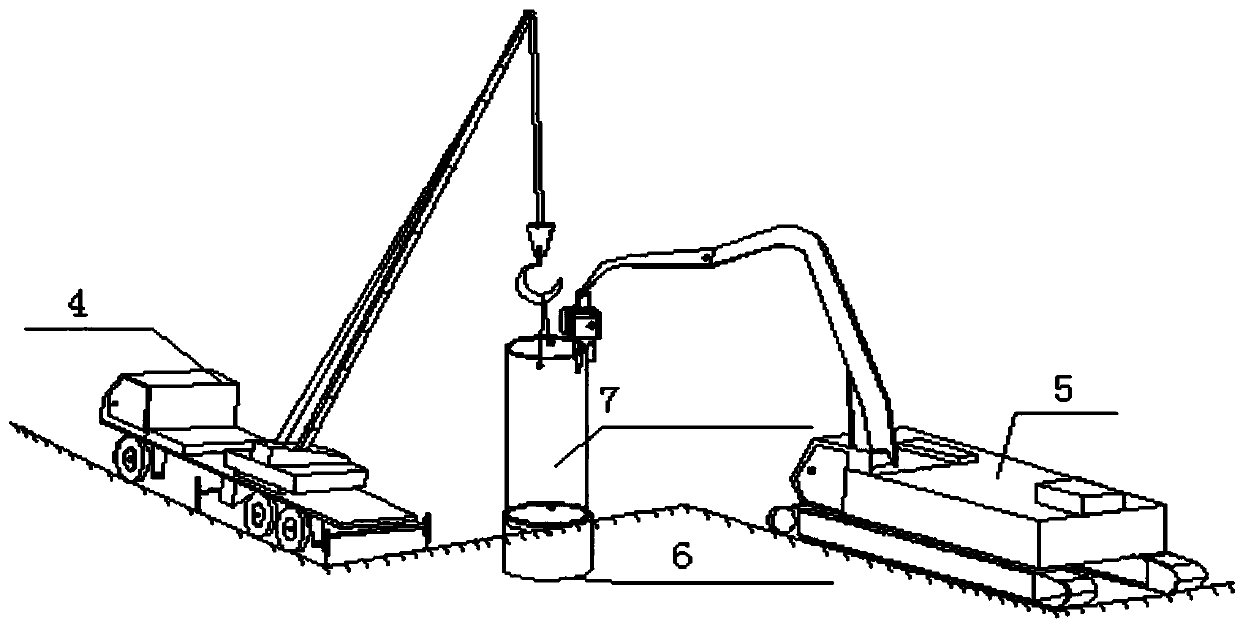

[0032] Such as figure 1 and figure 2 As shown, a method of rotary drilling and dry excavation with double steel casings for bored piles of viaducts, in which an aperture steel casing 6 is arranged above the long casing 7 of the pile body.

[0033] Preferably, the following steps are included:

[0034] Step 1: Use the total station to stake out to determine the hole position of the pile foundation, and the rotary drilling drill 1 is centered and in place through computer numerical control;

[0035] Step 2: Rotary drilling drill 1 first excavates the hole with the designed pile diameter drill bit 3, and embeds the steel casing of the hole and installs it in place;

[0036] Step 3: Rotary Drilling Drill 1 Replace the pilot hole drill bit 2 Take the hole to the length of the pile body long casing length pile body earthwork;

[0037] Step 4: The lifting crane and the vibrating hammer cooperate with each other to drive the steel casing into the soil of the pile body;

[0038] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com