Treatment process and system of nutrient self compensation and difficult-to-degrade industrial wastewater

A technology for industrial wastewater and treatment process, applied in the field of water treatment, can solve problems such as affecting the treatment effect of activated sludge section, increasing sludge treatment and disposal input, reducing carbon source nutrients, etc., to increase sludge concentration and system treatment capacity. , The effect of reducing sludge treatment and disposal costs and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

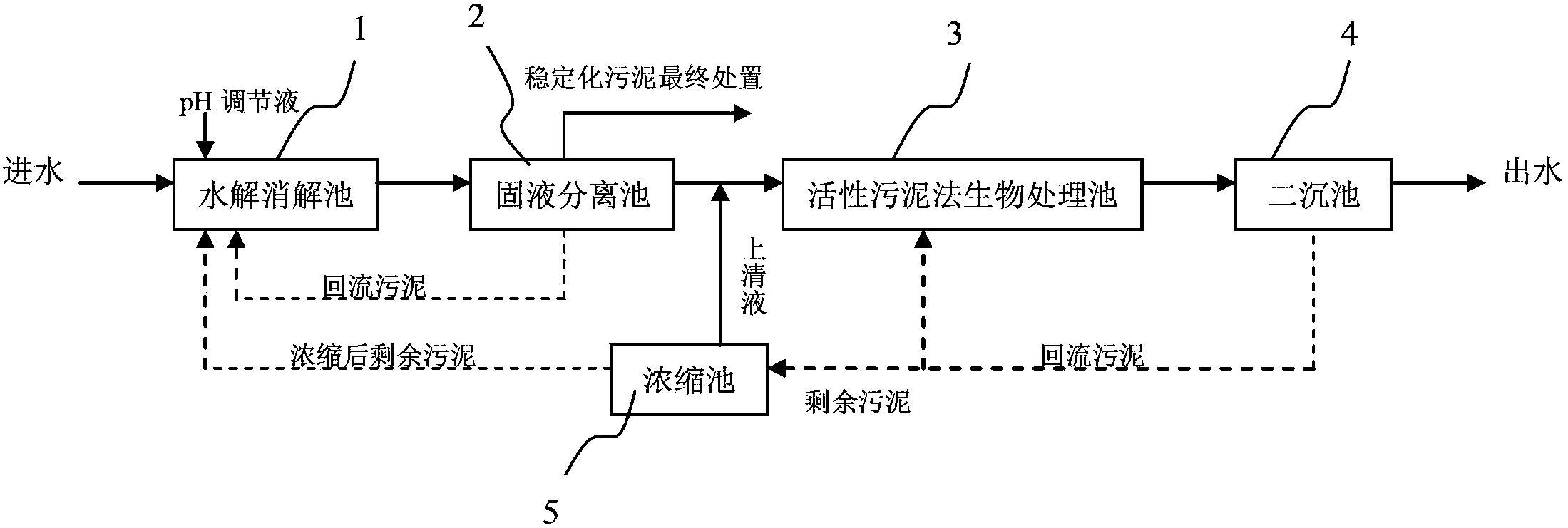

[0058] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

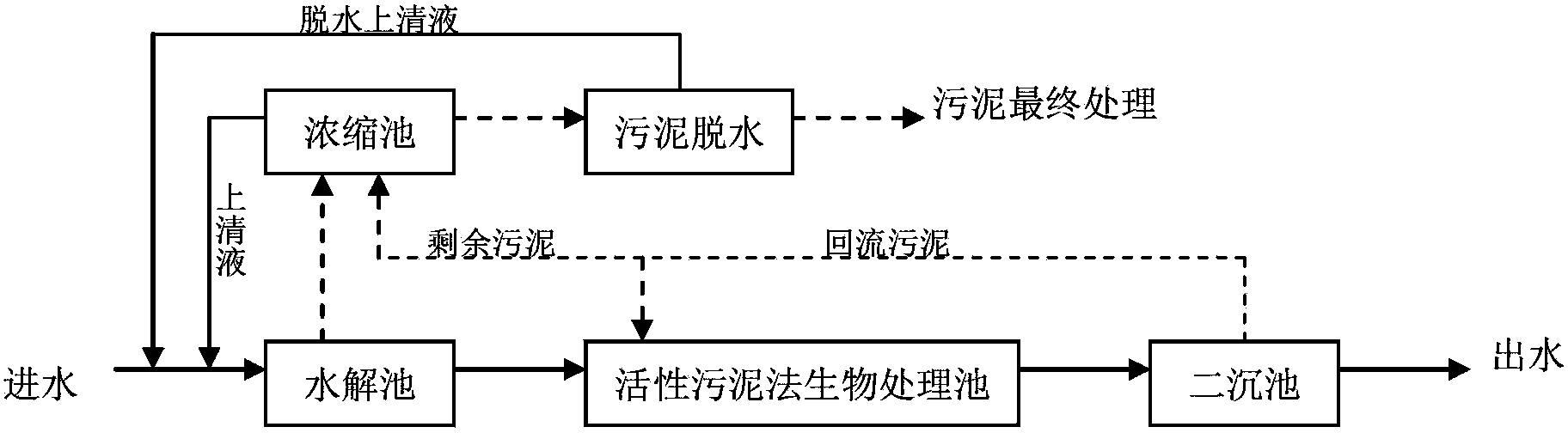

[0059] The process of the present invention can make full use of the effective nutrients of the sludge in the treatment system itself by appropriately improving the treatment process of the existing sewage treatment plant, which not only realizes the resource utilization of the sludge through the self-compensation of the nutrients, but also The purpose of sludge reduction has been achieved.

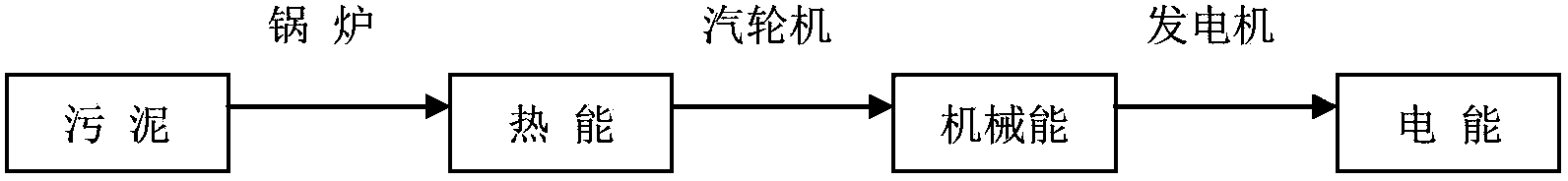

[0060] The principle of the process of the present invention (new technology of nutrient self-compensation and excess sludge reduction in refractory industrial wastewater treatment plants) is: without increasing a lot of investment, through appropriate improvement of the process route, the residual activity of the original discharge system All the sludge is returned to the hydrolysis and digestion tank, which greatly increases the sludge concentration in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com