Coal seam drilling hole-collapse preventing lower sleeve device capable of drilling along with drill and drilling method

A technology of anti-collapse holes and propulsion devices, applied in drilling equipment and methods, drilling equipment, earthwork drilling and mining, etc., can solve problems such as too late grouting, affecting coal mine safety production, and ineffective hole measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

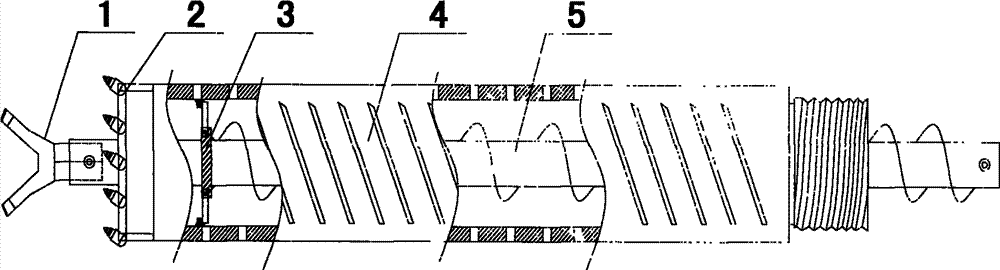

[0013] Such as figure 1 As shown, the soft coal seam drilling anti-collapse hole drilling device provided by the embodiment of the present invention is specifically composed of a horn drill bit (1), a barrel drill bit (2), a combined propulsion device (3), and a mesh sleeve (4) , Twist drill pipe (5) composition.

[0014] Connect the horn drill bit (1) to the top of the twist drill rod (5), fix the combination propulsion device (3) to the twist drill rod (5) at the same time, and connect the barrel drill bit (2) to the mesh sleeve (4) , and insert the assembled cylindrical drill (2) from the front side of the horn drill (1) and rotate, so that the combined propulsion device (3) is flexibly connected with the clamping plate inside the cylindrical drill.

[0015] In the anti-collapse device, the horn drill bit (1) and the twist drill rod (5) can be freely extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com