Method for repeated hole sealing on gas extraction drilling hole by rotary jet grouting and solidifying

A technology of gas drainage and hole sealing, which is applied in the direction of gas discharge, mining equipment, earthwork drilling, etc., can solve the problems of short service life of drilling holes and low concentration of gas drainage, and achieves wide practicability, low cost, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] The drilling and sealing method for mine gas drainage of the present invention adopts instruments such as drill bits, drill pipes, drilling rigs, extraction pipes, bladders, high-pressure rotary spraying equipment, liquid injectors, and uses rotary spraying solidified materials as sealing materials ,Specific steps are as follows:

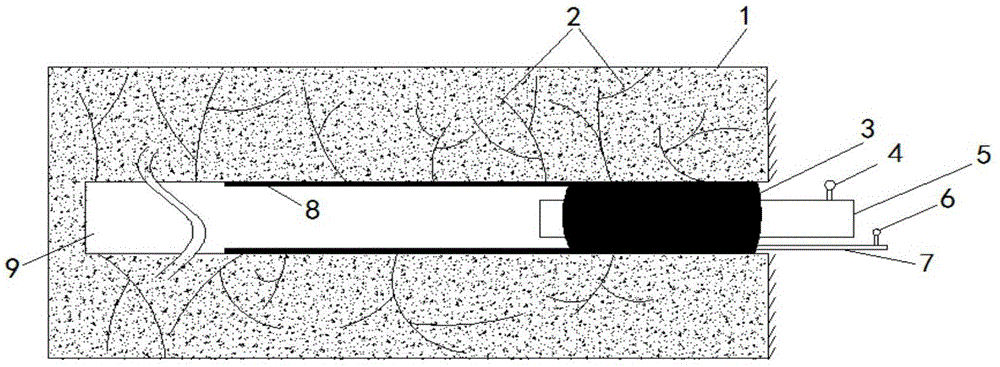

[0018] Such as figure 1 As shown, first use a drill bit of Φ113mm to construct a drill hole 9 with a required depth on the coal body, drill the drill bit to the required depth, and then drill back, and use high-pressure rotary spraying equipment to evenly spray the solidified material on the wall surface of the drill hole 9, A dense sealing layer 8 is formed, the thickness of the sealing layer 8 is 0.1-0.5mm, and the sealing length is 12m; the pressure of the high-pressure rotary spraying equipment can reach 10-15Mpa. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com