FeCrVTiCu high-entropy alloy and preparation method thereof

A high-entropy alloy and metal element technology, which is applied in the field of FeCrVTiCu high-entropy alloy and its preparation, can solve the problem of complex preparation process of high-entropy alloy powder metallurgy, affecting material tensile properties, fatigue properties, and low melting point metals are easy to evaporate and burn. and other problems, to achieve the effect of smaller grain size, lower cost and increased plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

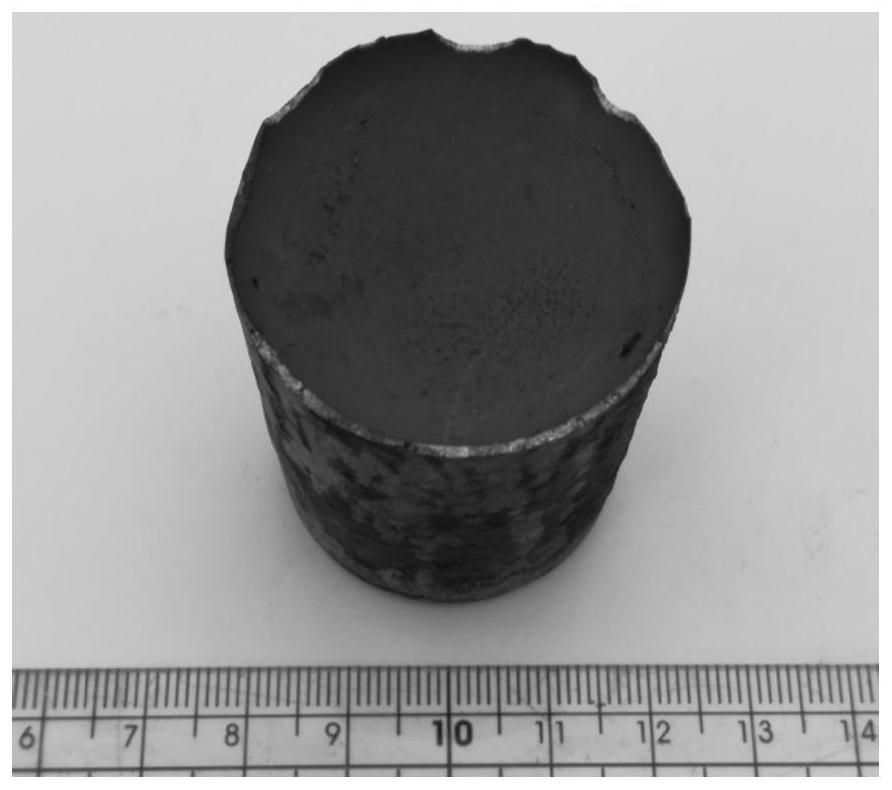

[0037] The preparation method of FeCrVTiCu high-entropy alloy of the present invention comprises the steps:

[0038] Fe, Cr, V, Ti, Cu five metal elements are taken as raw materials, mixed according to the atomic percentage of the FeCrVTiCu high-entropy alloy, pressed into a billet, and then smelted to obtain the FeCrVTiCu high-entropy alloy;

[0039] The specific operation of the smelting is: firstly evacuate until the pressure in the smelting furnace is lower than 0.005Pa, then fill in argon to make the pressure in the furnace reach 14-20Pa, and then start to heat up at a rate of 55-65°C / min to 350-450°C, keep warm for 1-5min, then raise the temperature to 750-850°C at a rate of 35-45°C / min, keep warm for 3-8min, then raise the temperature to 1150-1250°C at a rate of 25-35°C / min, keep warm 3~8min, then raise the temperature to 1550~1650℃ at a rate of 15~25℃ / min, keep warm for 3~8min, then raise the temperature to 1750~1800℃ at a rate of 15~25℃ / min, keep warm for 8~15min, and...

Embodiment 1

[0052] The FeCrVTiCu high-entropy alloy is smelted using the following atomic percentage raw materials:

[0053] FeV50: 20%, Cr: 20%, Fe: 20%, Ti: 20%, Cu: 20%, wherein FeV50 is a vanadium-iron alloy containing 50wt% vanadium.

[0054] Prepare by following steps:

[0055] 1) Billet making: Take the raw materials containing the constituent elements of the FeCrVTiCu high-entropy alloy, mix them in a stainless steel ball mill tank for 20 minutes according to the element percentage, and the rotation speed is 200r / min; then press them into rods with a pressure of 30Mpa; The raw material is put into a graphite crucible coated with yttrium oxide, and then put into an induction melting furnace for melting;

[0056] 2) Melting: first use 2X-8 mechanical pump to evacuate to below 5Pa, then turn on TK-200 diffusion pump to evacuate below 0.005Pa, then turn off the diffusion pump and inject argon to make the pressure in the furnace reach 15Pa. Turn on the induction melting furnace to st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com