Technique for squeezing through-hole high dummy club on sheet

A technology of high bosses and sheet materials, which is applied in the field of high bosses for extrusion through holes of thick sheets, can solve problems such as product cracks, uneven cross-sections, and breakage, and achieve the effects of improving plasticity, suppressing tensile stress, and preventing cracks Produce and extend the effect

Active Publication Date: 2010-11-24

广州市华冠精冲零件有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when punching through the high boss of the hole, that is, when the height of the boss to be punched out is greater than the thickness of the sheet, the above process will cause the tensile stress of the material to be too large in the process of turning the hole, so that the material is required to have good ductility and convexity. Only products with low platform requirements and low precision requirements can be suitable; for products with high size requirements, high strength, thick materials, and bosses higher than the thickness of the material, it is difficult to achieve using conventional stamping processes, usually with pre-punching Products made by hole technology will have cracks, breakage in the middle, and uneven cross-section

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

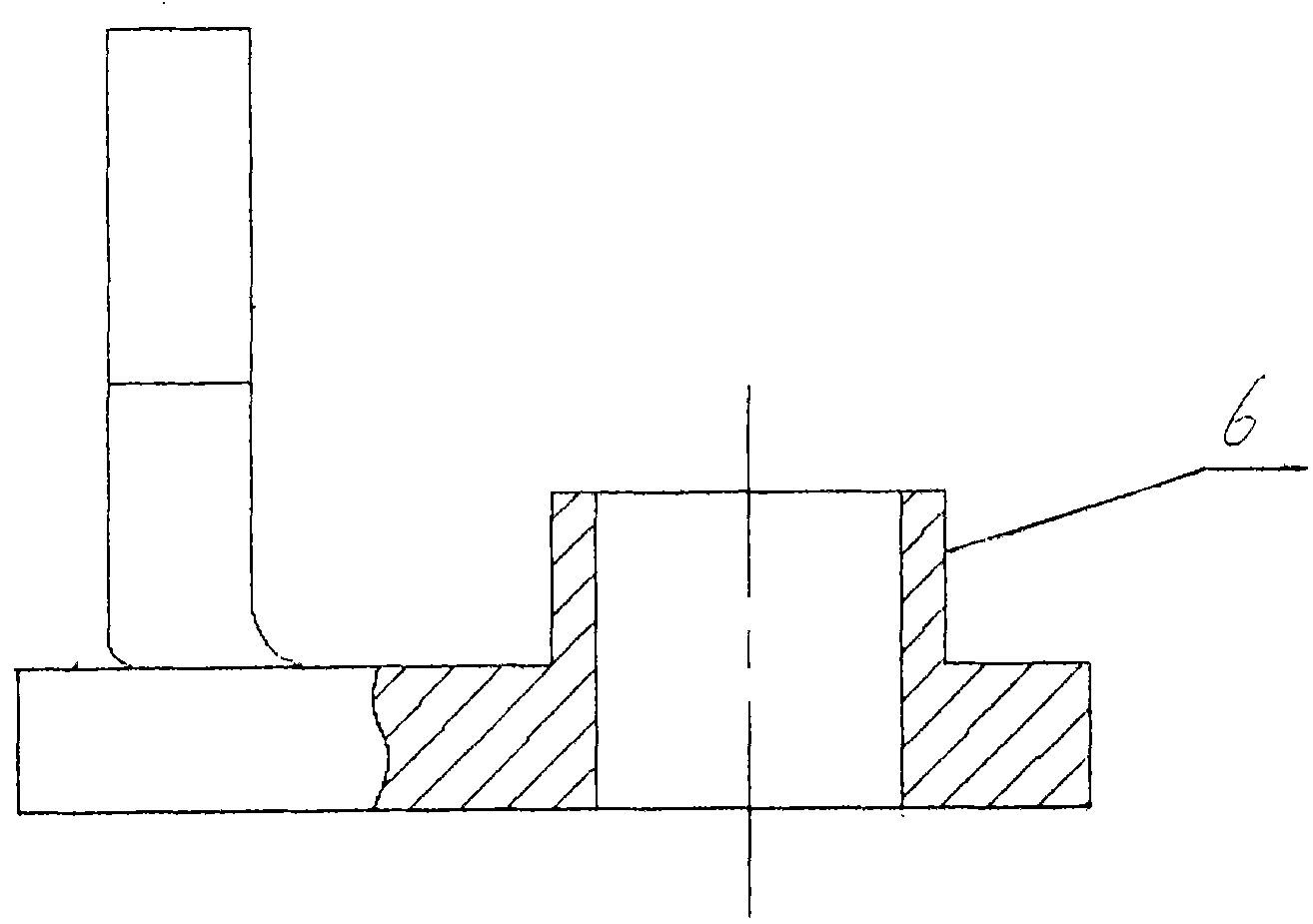

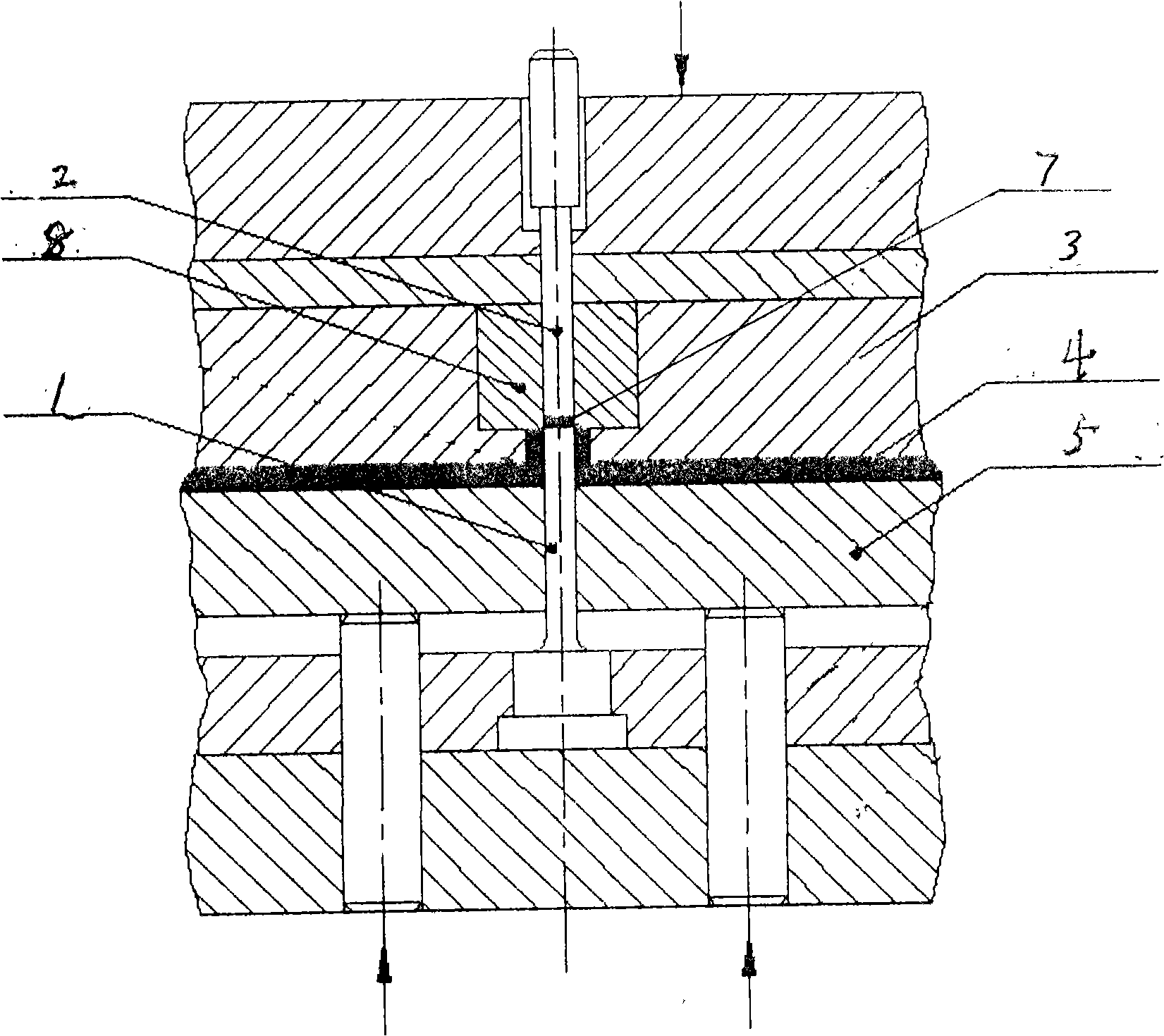

Abstract

The invention relates to a process to extrude a high lug boss in a through hole of a sheet metal, in particular to a process to extrude a high lug boss in a through hole of a sheet metal through cold extrusion, wherein, the height of the lug boss is greater than the thickness of the sheet metal. The technology of the invention adopts a fine blanking machine, which is not stressed uniformly in three directions, to directly cold squeeze the sheet metal, thus improving the plasticity of the metal, impeding the intergranular deformation of materials and changing intergranular deformation into intragranular deformation; the tensile stress can be greatly inhibited, thus preventing the emergence and expansion of cracks and further avoiding the problem of large displacement in the prior art, which causes excess tensile force, easy breaking and tension fracture of the lug boss, etc.

Description

The Technology of Sheet Metal Extrusion Through Hole and High Boss technical field The invention relates to a process for extruding a through-hole high boss on a thick plate, in particular to a process for cold-extruding a through-hole high boss on a thick plate, and the height of the boss is greater than the thickness of the plate. Background technique Cold extrusion is suitable for processing parts such as automobiles and door locks. It is characterized by fewer processes, short working hours, and rapid prototyping. The traditional process of stamping through-hole bosses uses pre-punching process holes, and then uses conical guide punches. Extrusion turning hole, the mold structure is simple, and can be implemented on a general press. However, when punching through the high boss of the hole, that is, when the height of the boss to be punched out is greater than the thickness of the sheet, the above process will cause the tensile stress of the material to be too large in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21D28/26B21D28/34

Inventor 黄伟雄黄宏伟陈登

Owner 广州市华冠精冲零件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com