Drilling device for laminated glass production

A drilling device and laminated glass technology, applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of long production cycle, high maintenance cost, high input cost, etc., and achieve stable power output and improved Stability, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

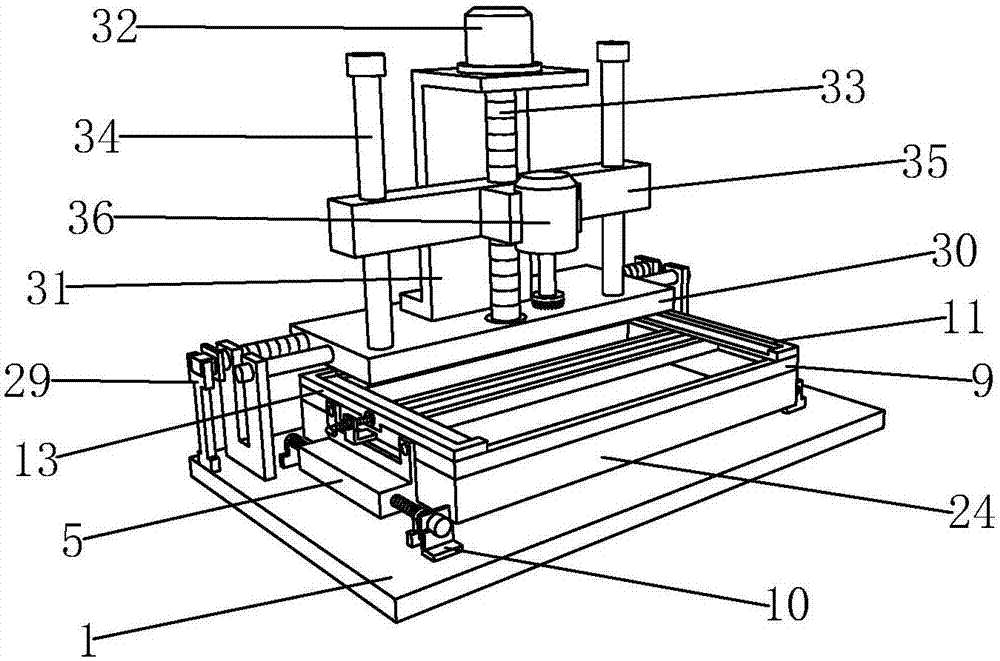

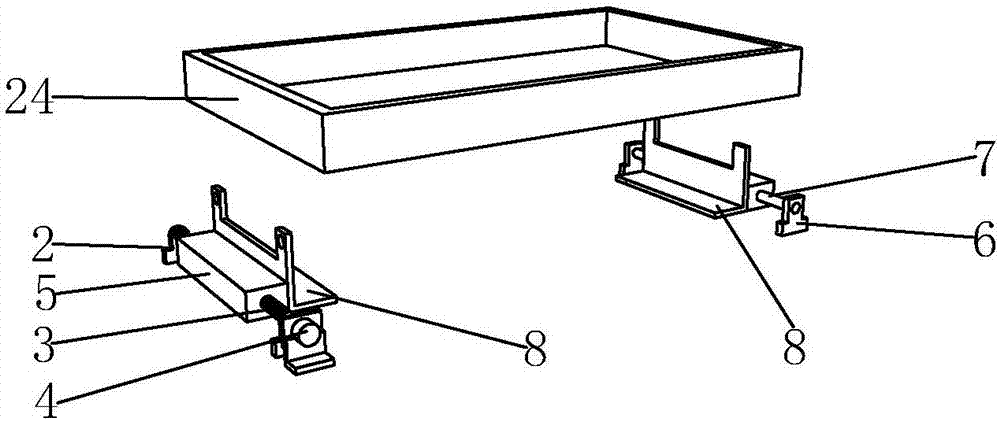

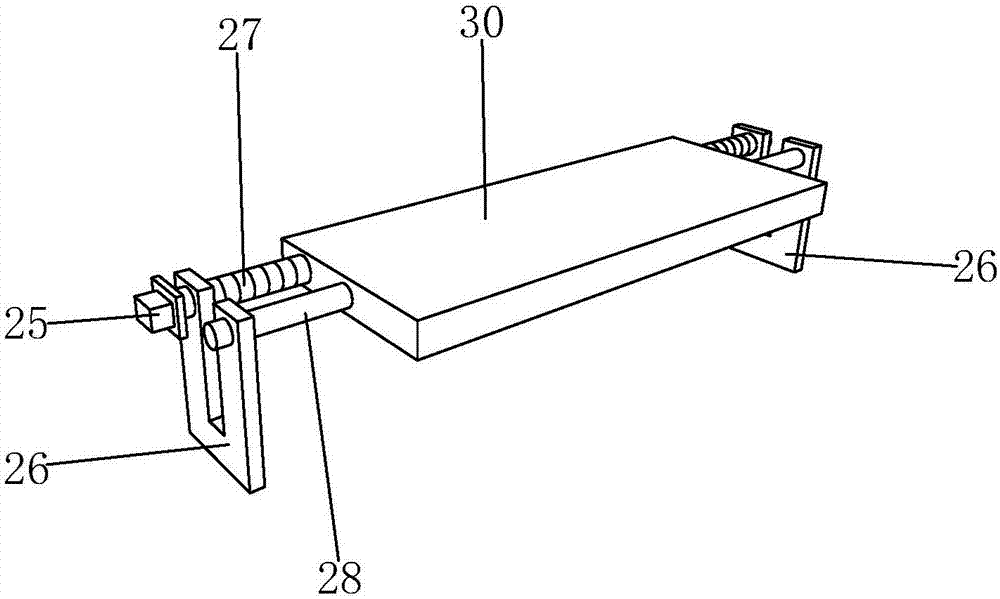

[0025] Such as Figure 1 to Figure 6 As shown, it is a drilling device for the production of laminated glass according to the present invention, including a working platform 1. In order to reduce the weight, the whole working platform 1 is made of light-duty high-strength materials, and the surface is treated with professional electroplating and baking varnish. It is smooth, beautiful and stable. . The working platform 1 is respectively provided with a driving mechanism, a screw mechanism and a fixing mechanism. The screw mechanism includes a support 2, a third screw 3 and a screw motor 4. The screw motor 4 is connected to one end of the third screw 3, and the third screw 3 is located on the support. Between the seats 2, the third screw rod 3 is provided with a support block 5, and the fixing mechanism includes a fixed seat 6 and a support rod 7, and the support rod 7 is arranged between the fixed seats 6, and the support rod 7 is provided with a support block 5, and the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com