Patents

Literature

33results about How to "Extended drilling range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

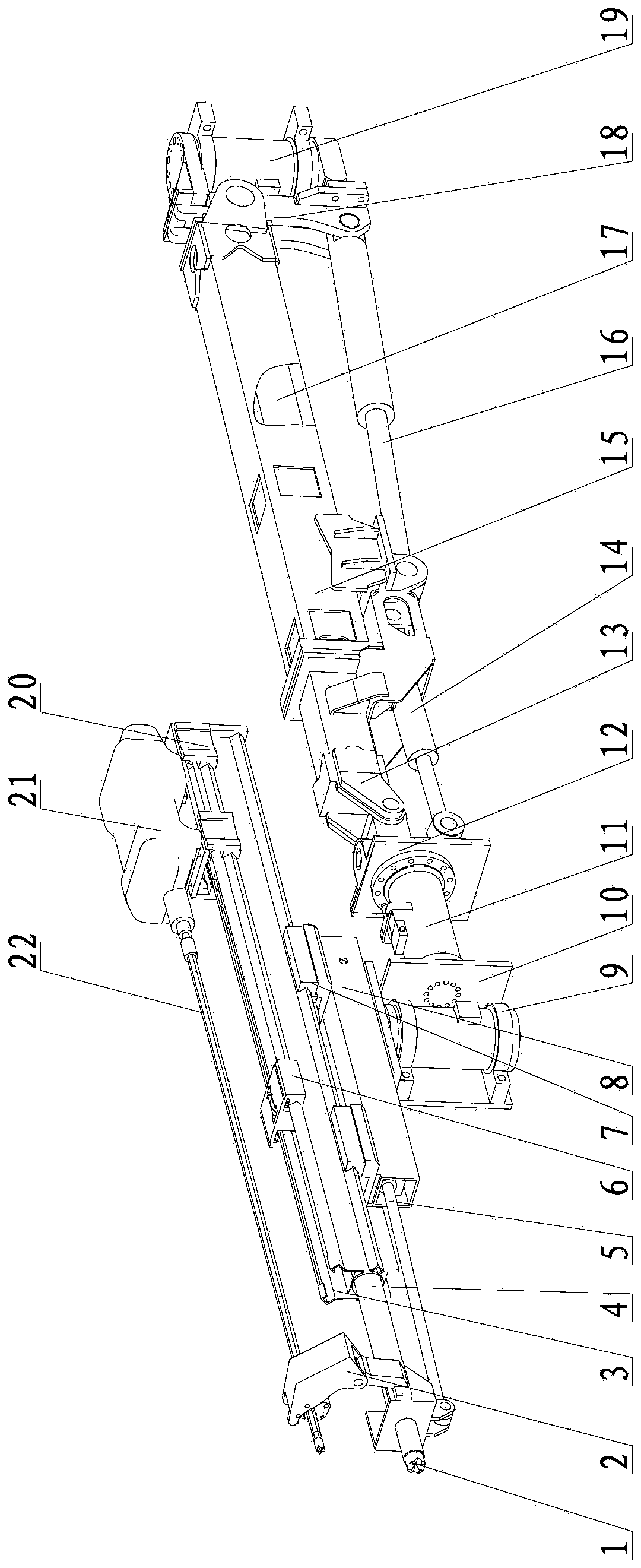

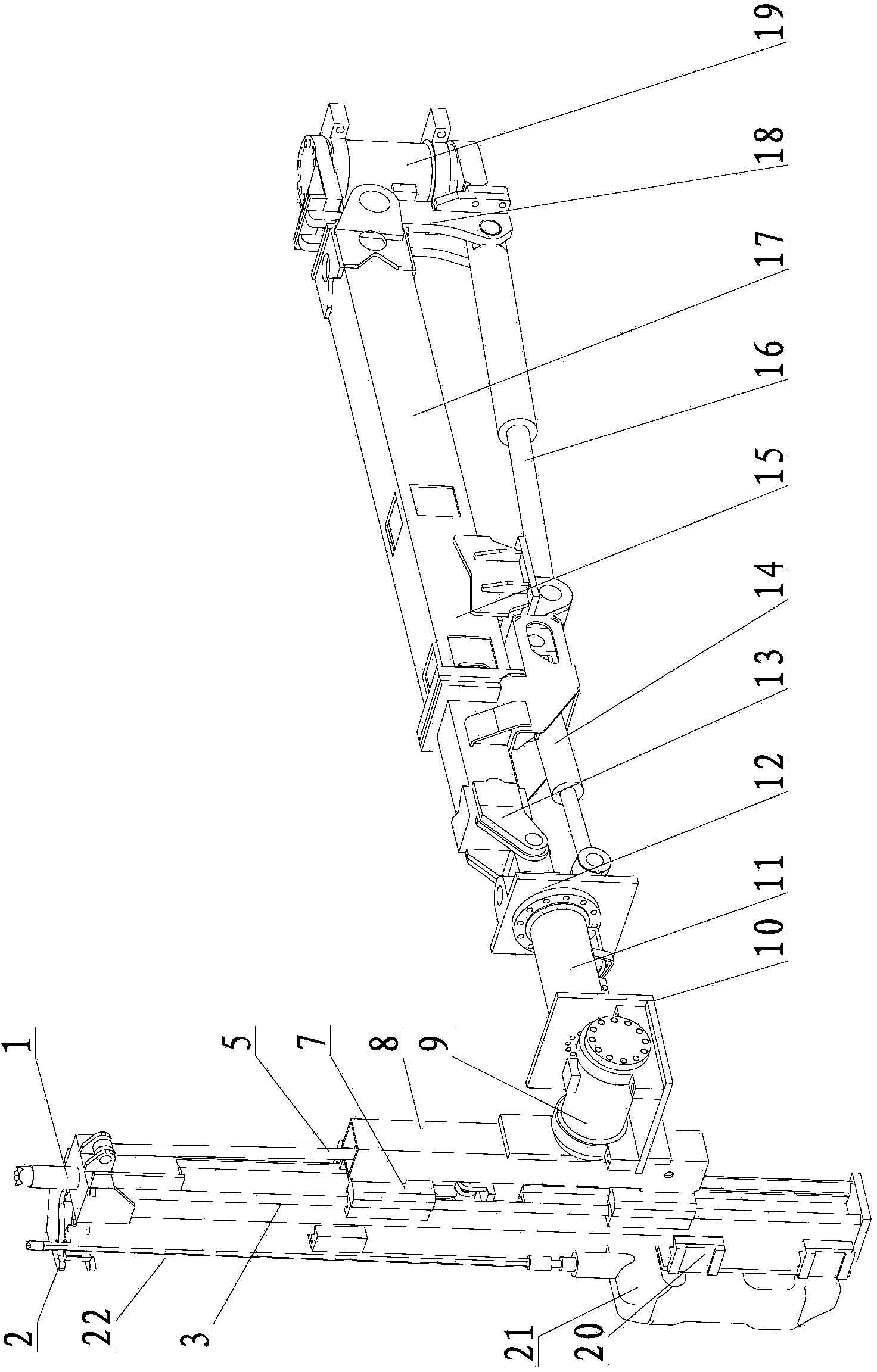

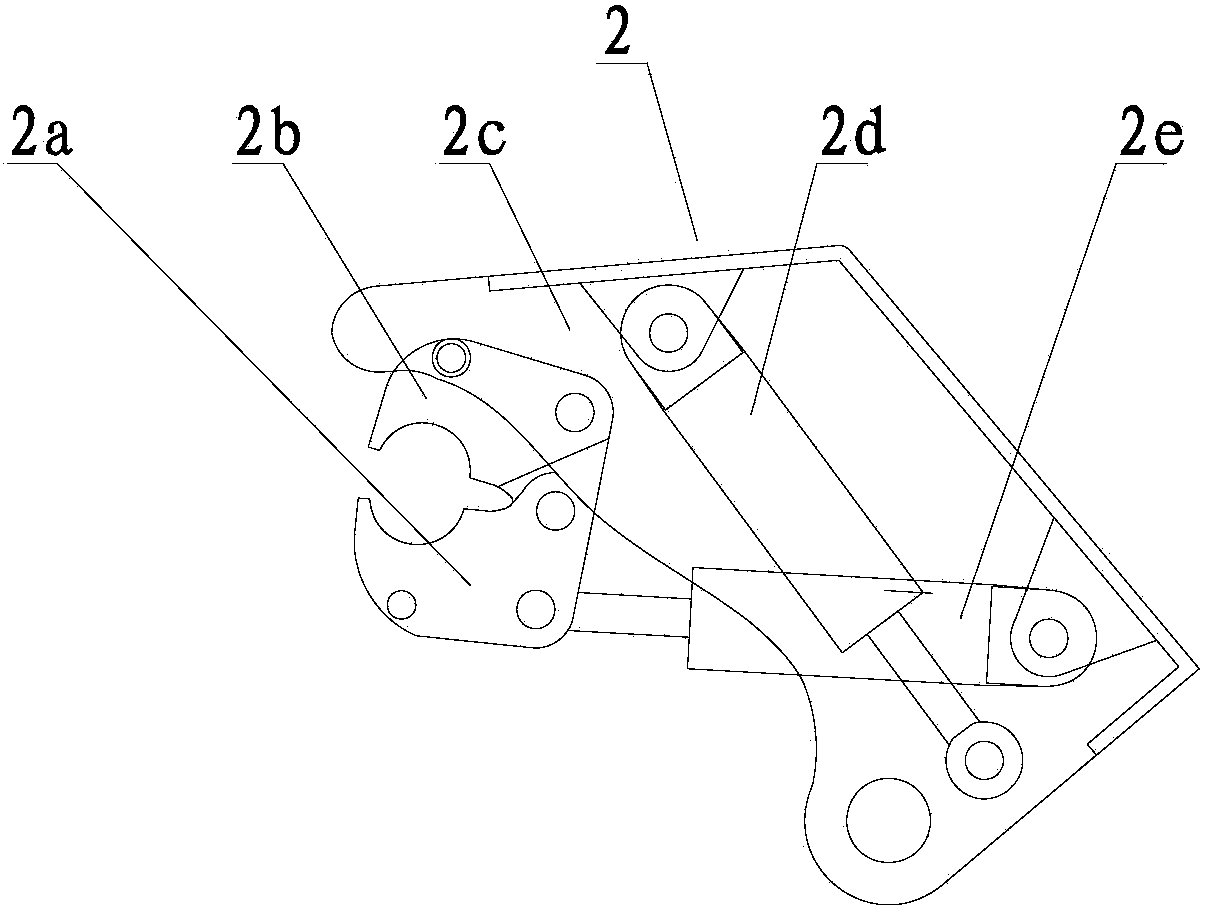

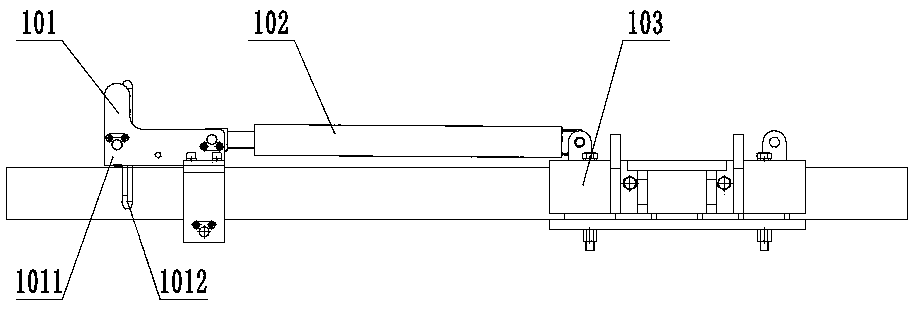

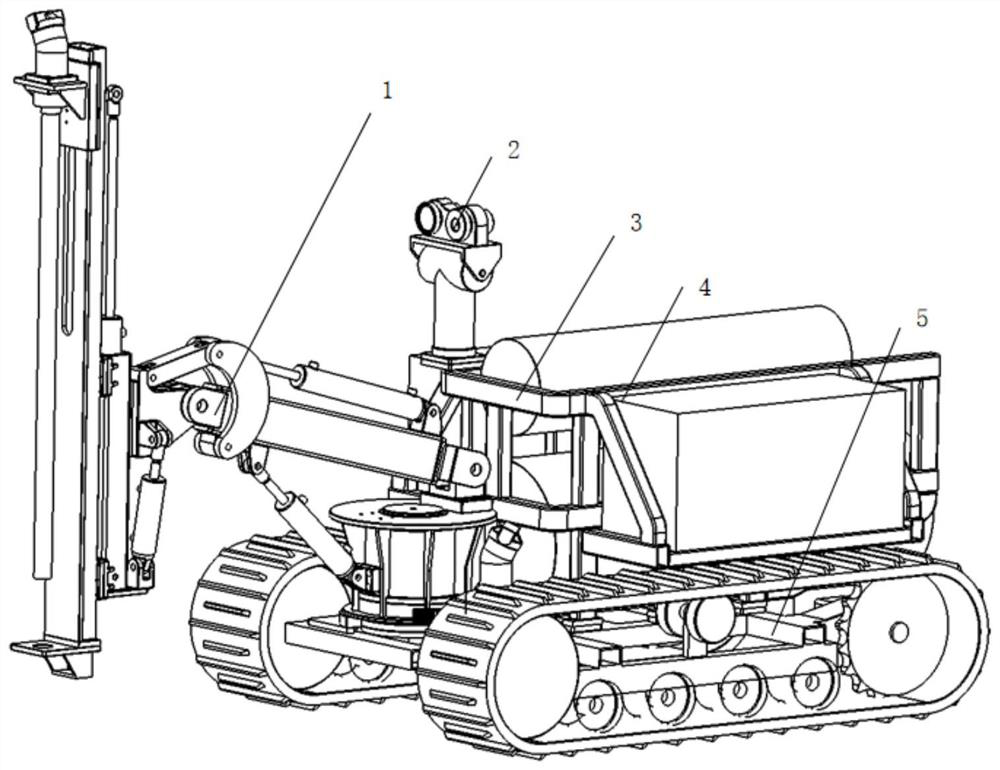

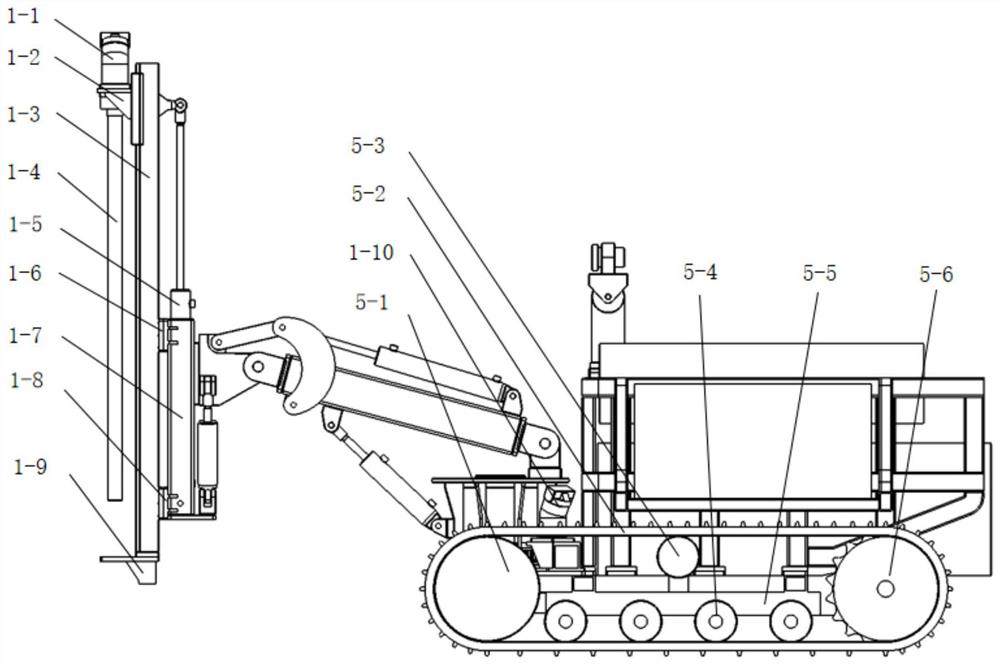

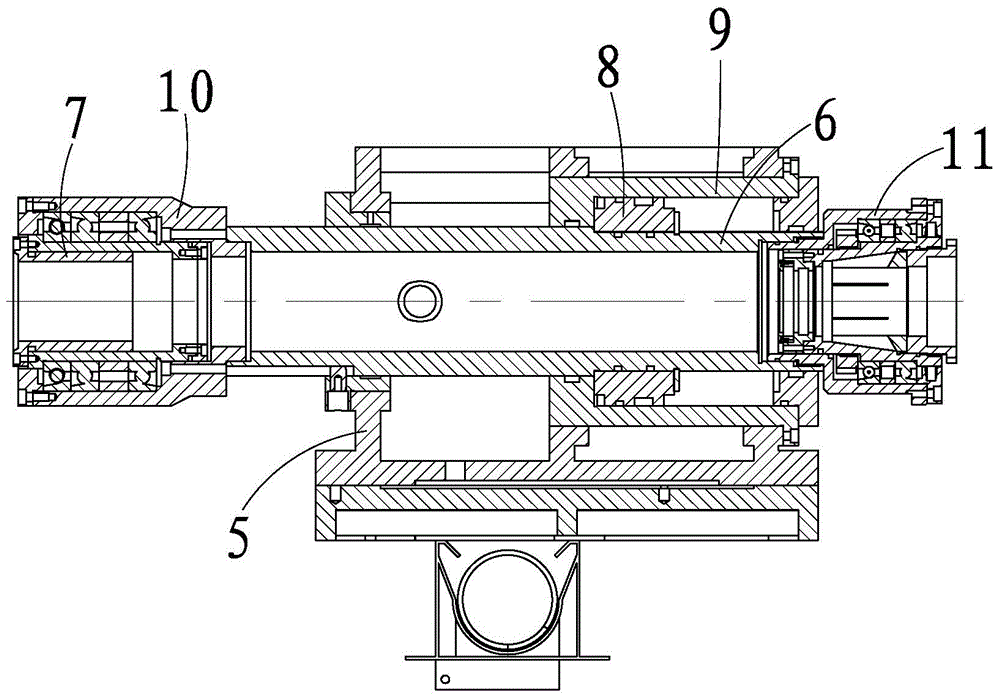

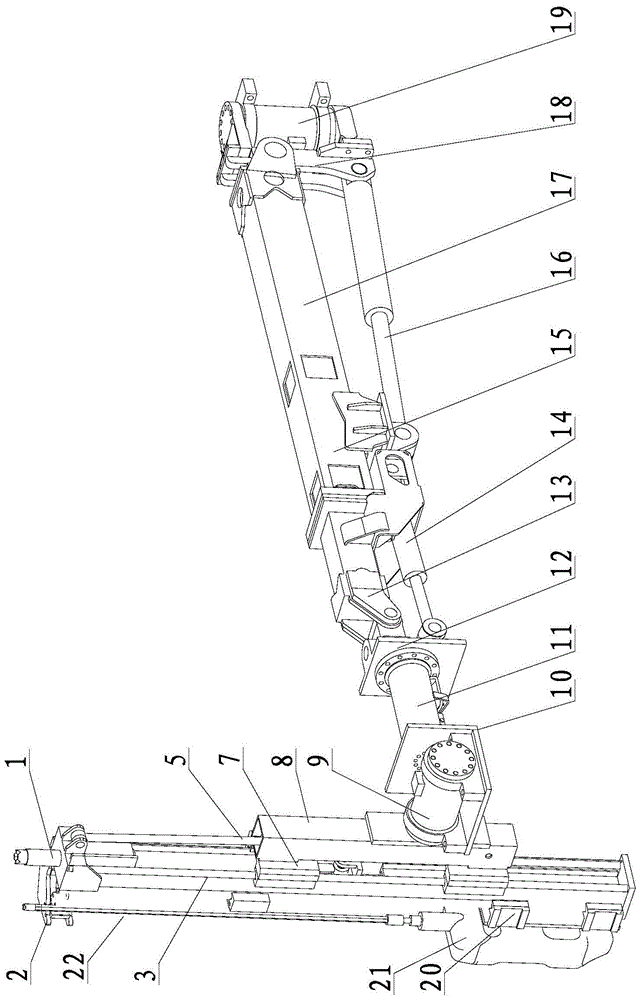

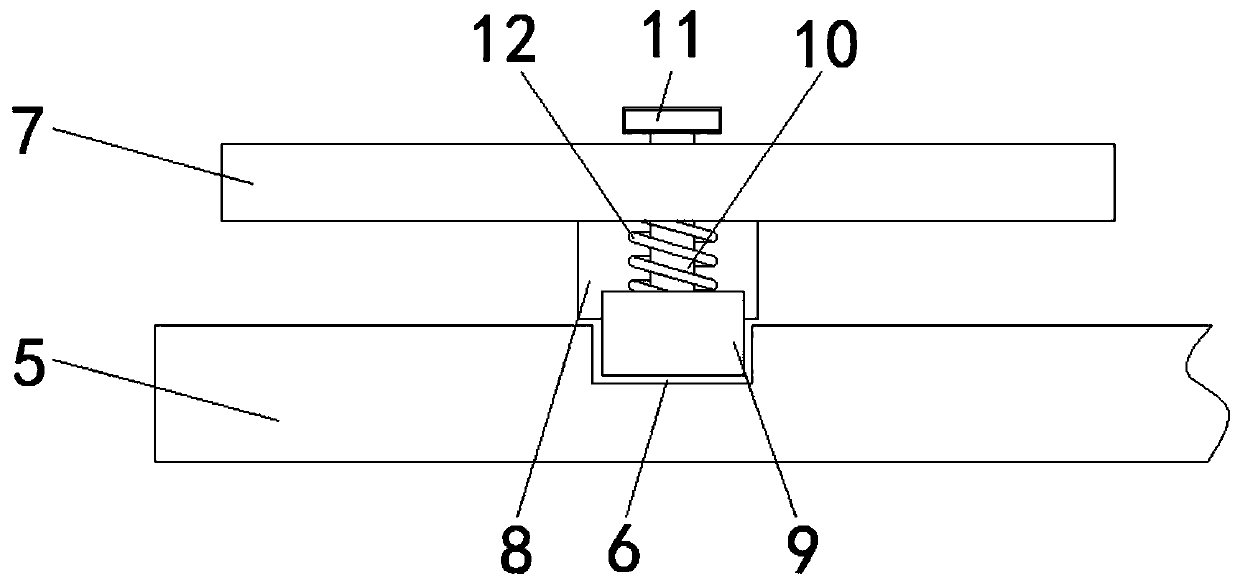

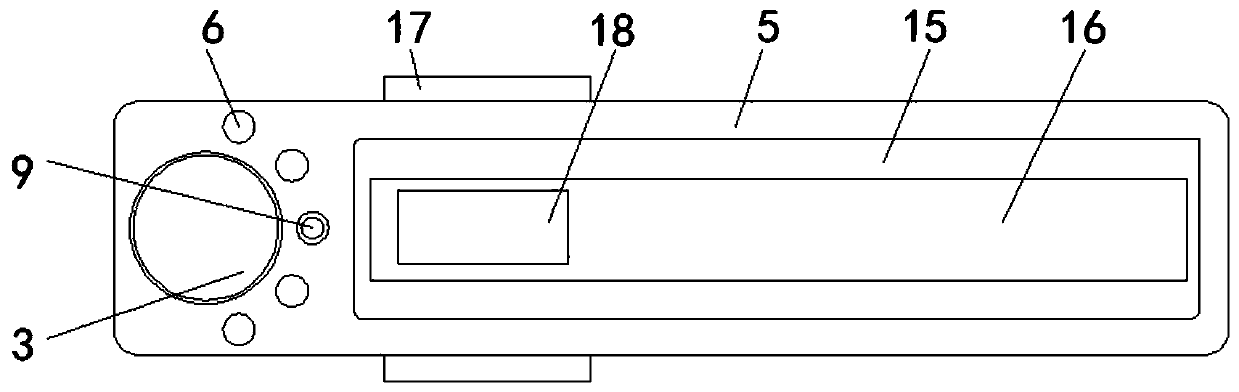

Drilling mechanism and drill loader

ActiveCN103485714AIncreased drilling rangeShorten the lengthDrilling machines and methodsPetroleum engineeringDeep hole drilling

The invention relates to a drilling mechanism and a drill loader. The drilling mechanism comprises a drilling arm and a bracket mounted on the drilling arm, a sliding frame is slidably arranged on the bracket, a sliding frame telescopic oil cylinder is arranged in the sliding frame, a positioning tip is fixed at one end of the sliding frame telescopic oil cylinder, the other end of the sliding frame telescopic oil cylinder is fixed in the sliding frame, and a brazing tool is fixed on the positioning tip. The telescopic oil cylinder is arranged in the sliding frame, and after the sliding frame telescopic oil cylinder extends, the long brazing tool can be mounted on the positioning tip on the end portion of the sliding frame to meet requirements on deep-hole drilling in engineering construction; after the sliding frame telescopic oil cylinder shortens, the length of the sliding frame can be greatly reduced, requirements on drilling of a top anchor rod hole by erecting the sliding frame in limited tunnel space can be met, drilling range is widened, and practicability is improved.

Owner:SANY HEAVY EQUIP

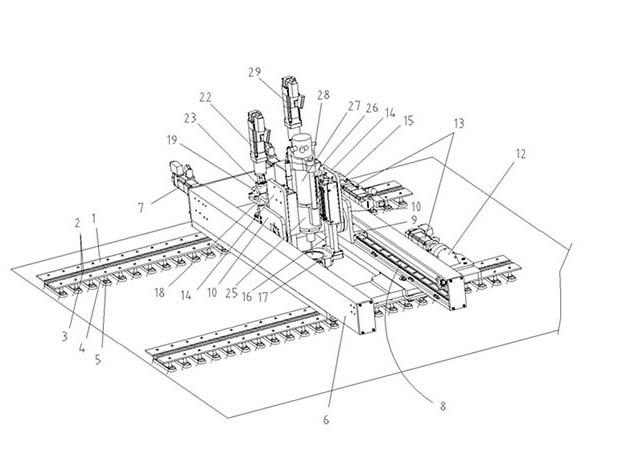

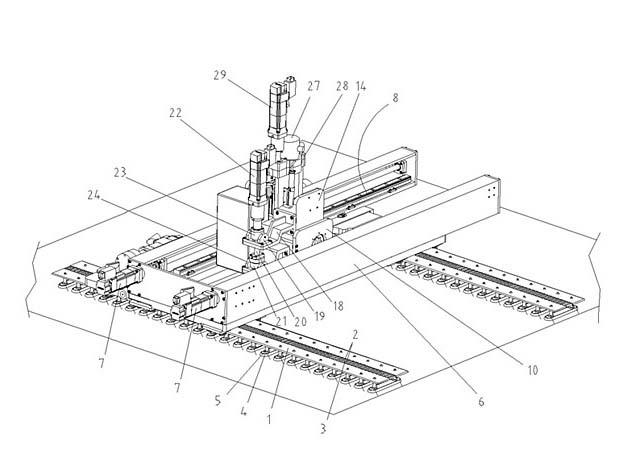

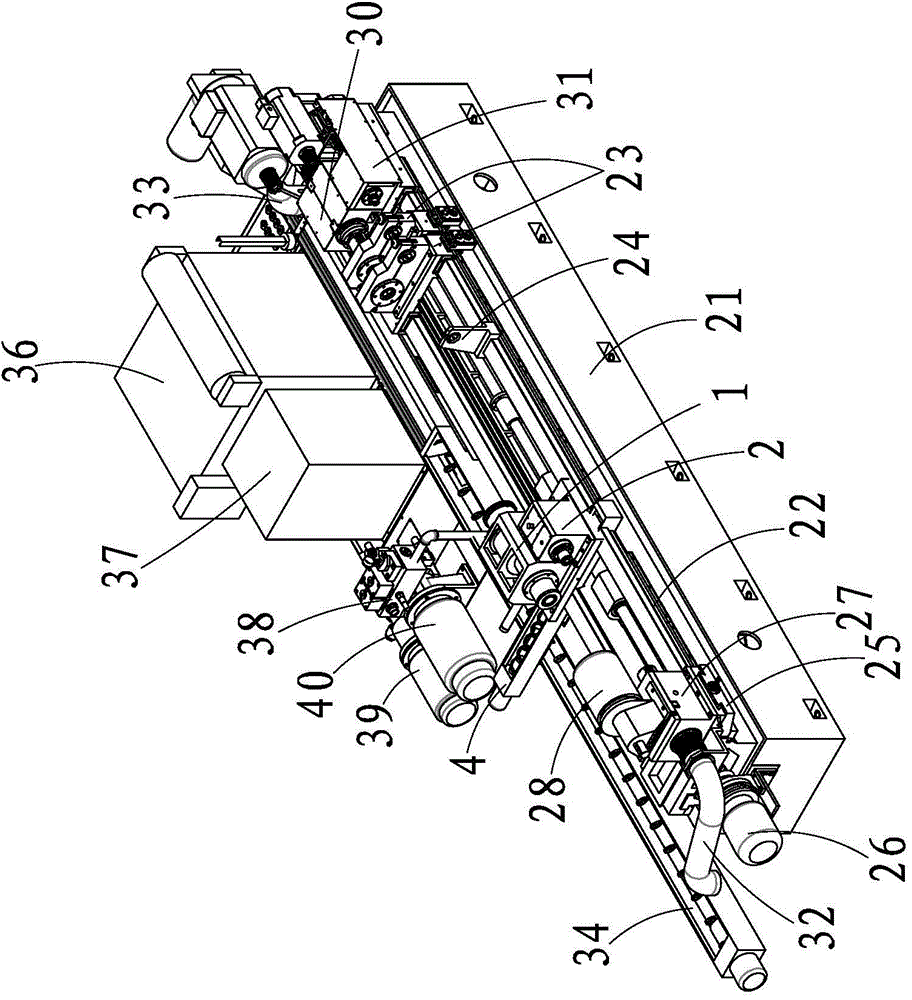

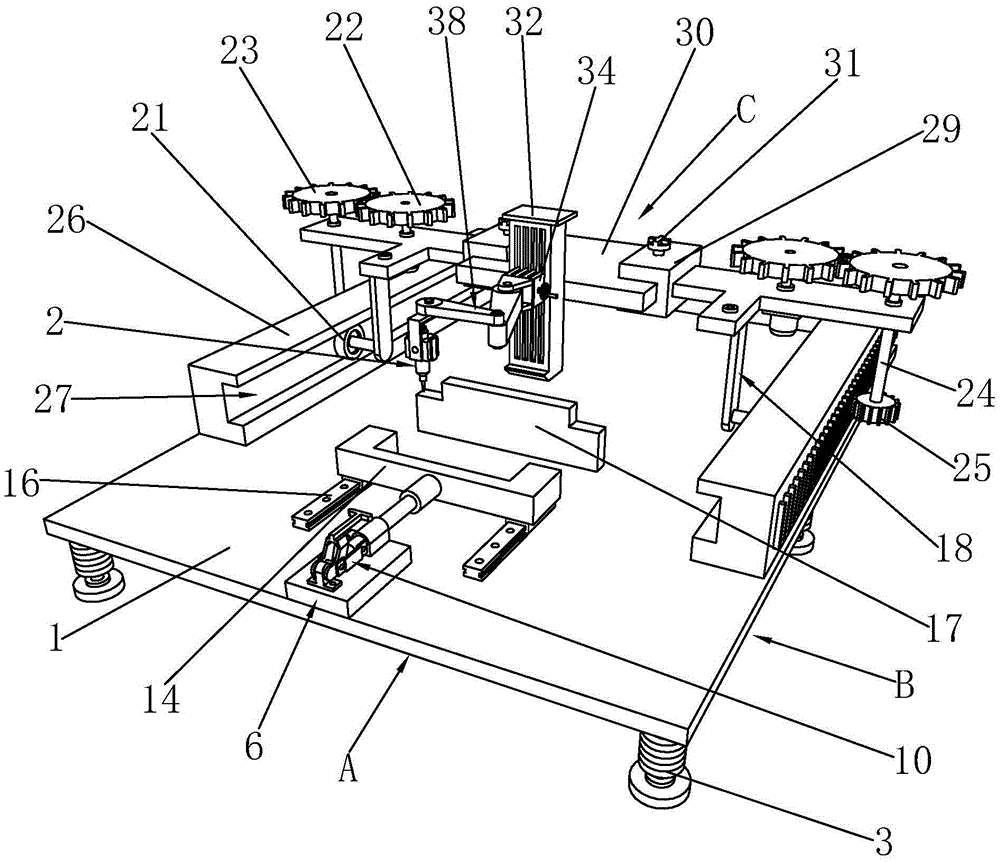

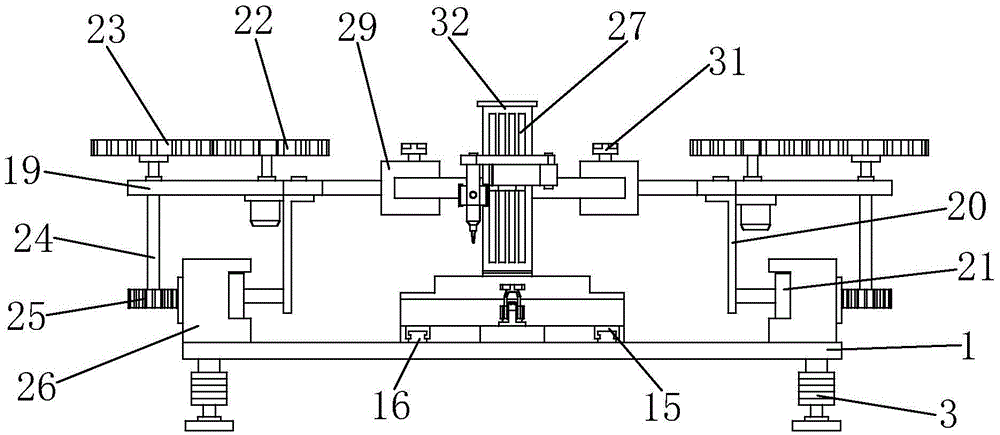

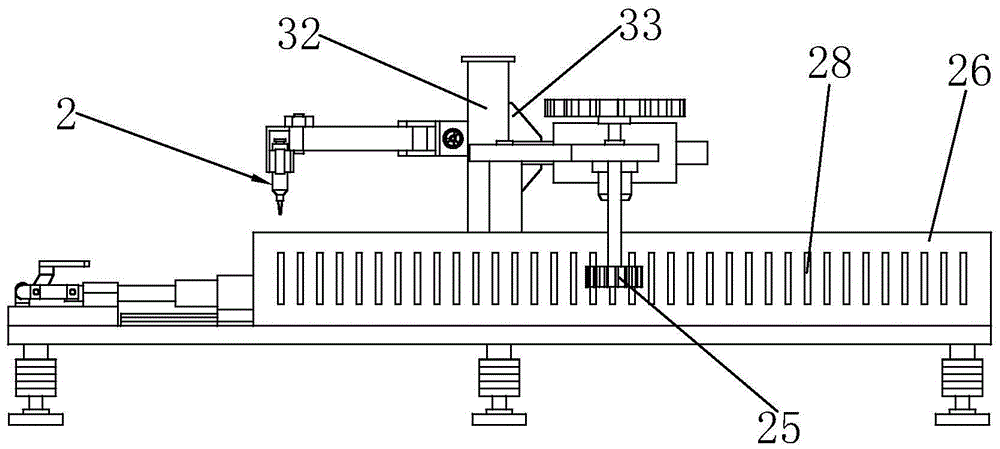

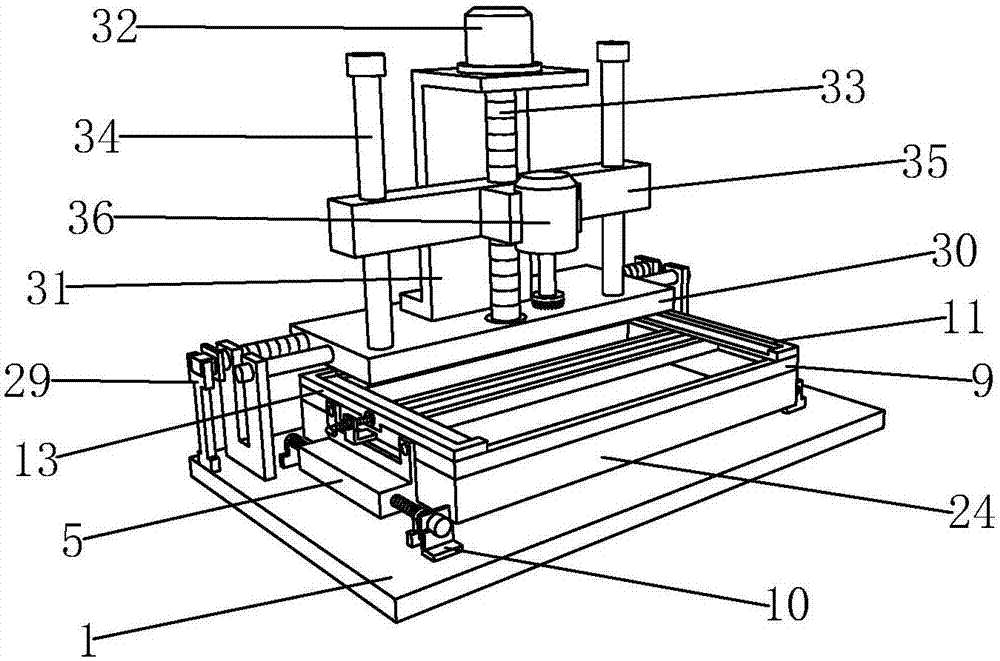

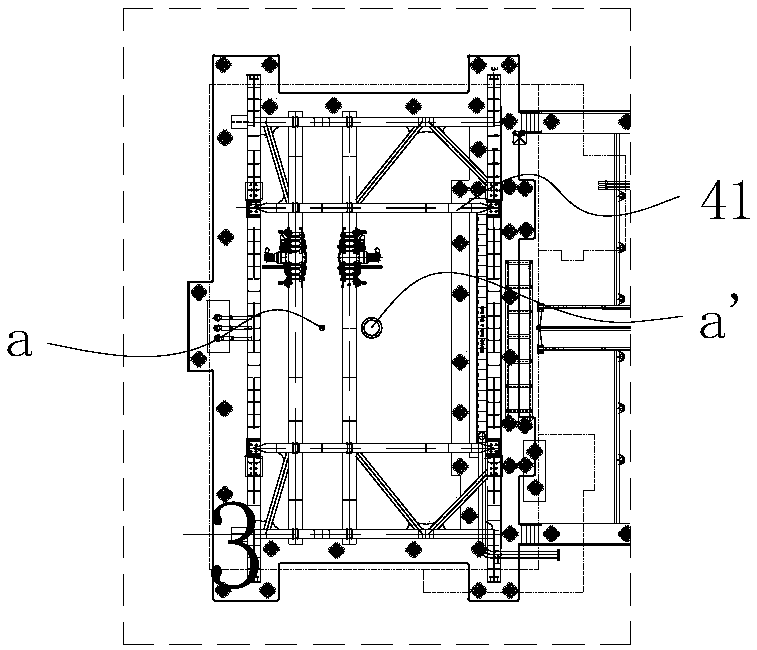

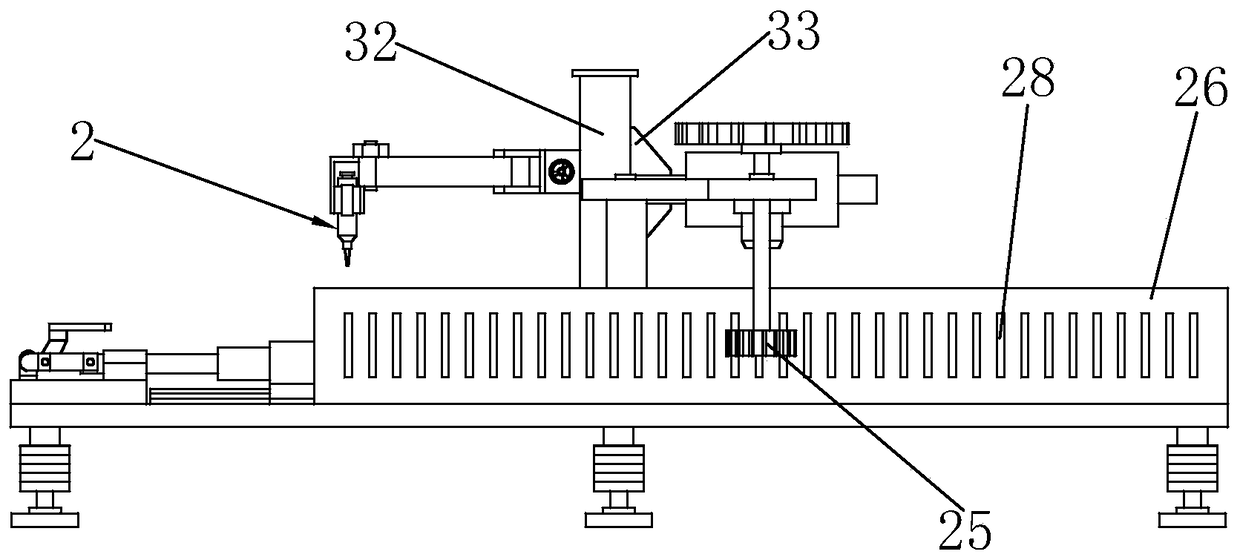

Arc surface drilling equipment

ActiveCN102198531AImprove drilling accuracyExtended drilling rangePortable drilling machinesBoring/drilling machinesElectricityEngineering

The invention discloses arc surface drilling equipment, which comprises two flexible tracks. A movable framework is arranged on the flexible tracks; a vertical plate is mounted on the movable framework via a linear guide rail; the vertical plate is rotatably connected with a swing plate; and an electric main shaft is mounted on the swing plate. The electric main shaft is slidably connected with the swing plate via a hoop, and the swing plate is connected with a swing driving mechanism. The electric main shaft can move longitudinally, transversely and vertically on the drilling equipment, and can swing and rotate, so a drilling range of the electric main shaft is expanded, absorption positions of the flexible tracks on the surface of a workpiece are not needed to be frequently changed, theworking intensity is reduced, the working efficiency is improved, and the processing cost is lowered; meanwhile, the drilling equipment is more stable, and the drilling precision is improved.

Owner:大连四达高技术发展有限公司

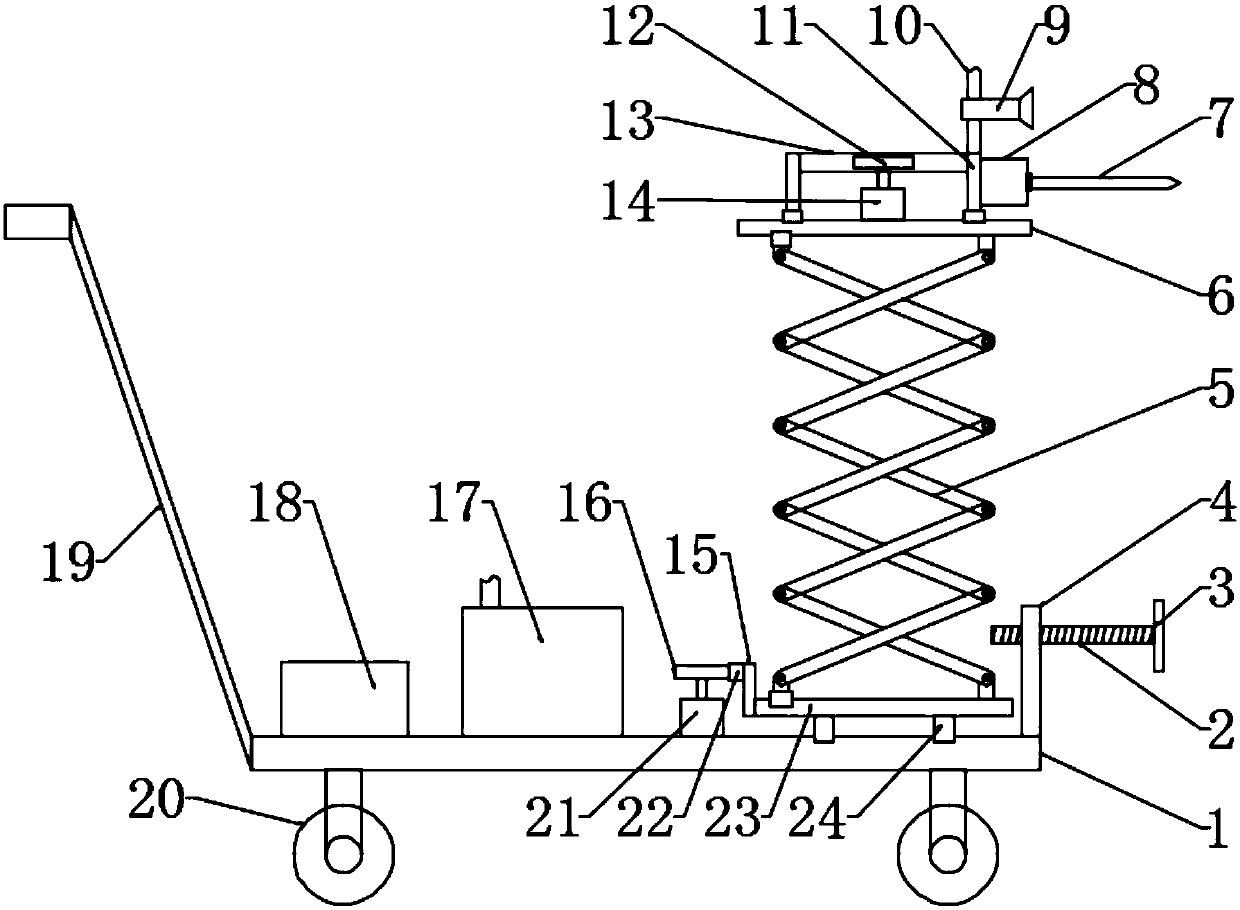

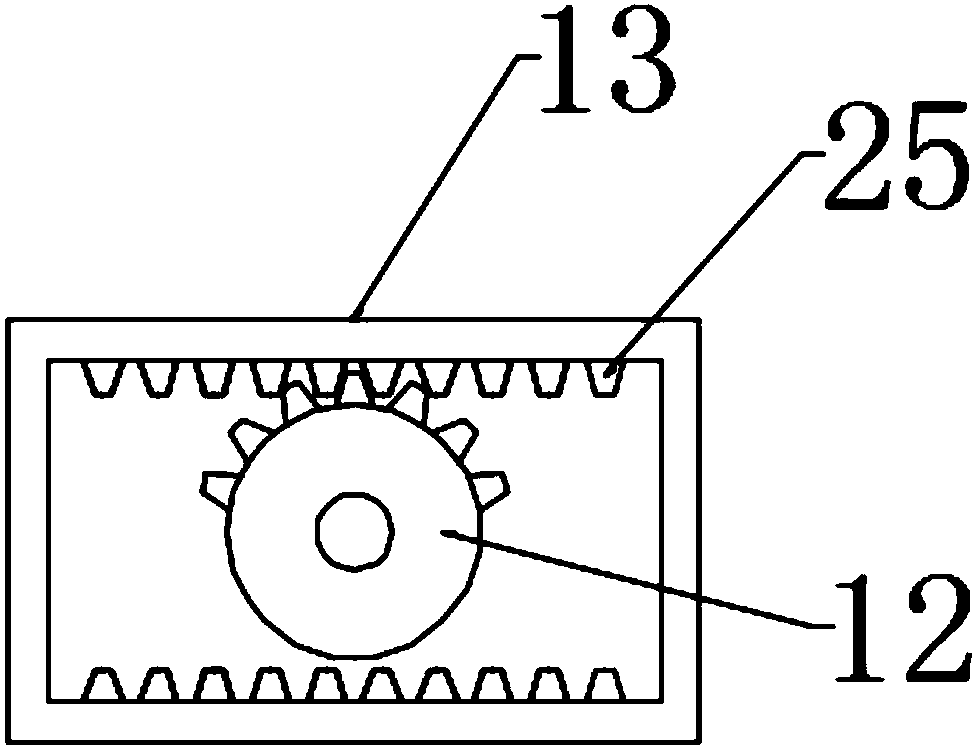

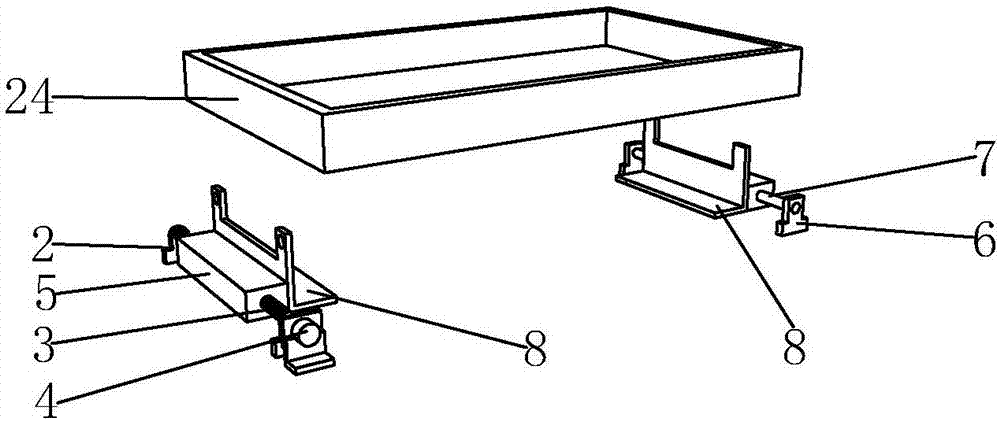

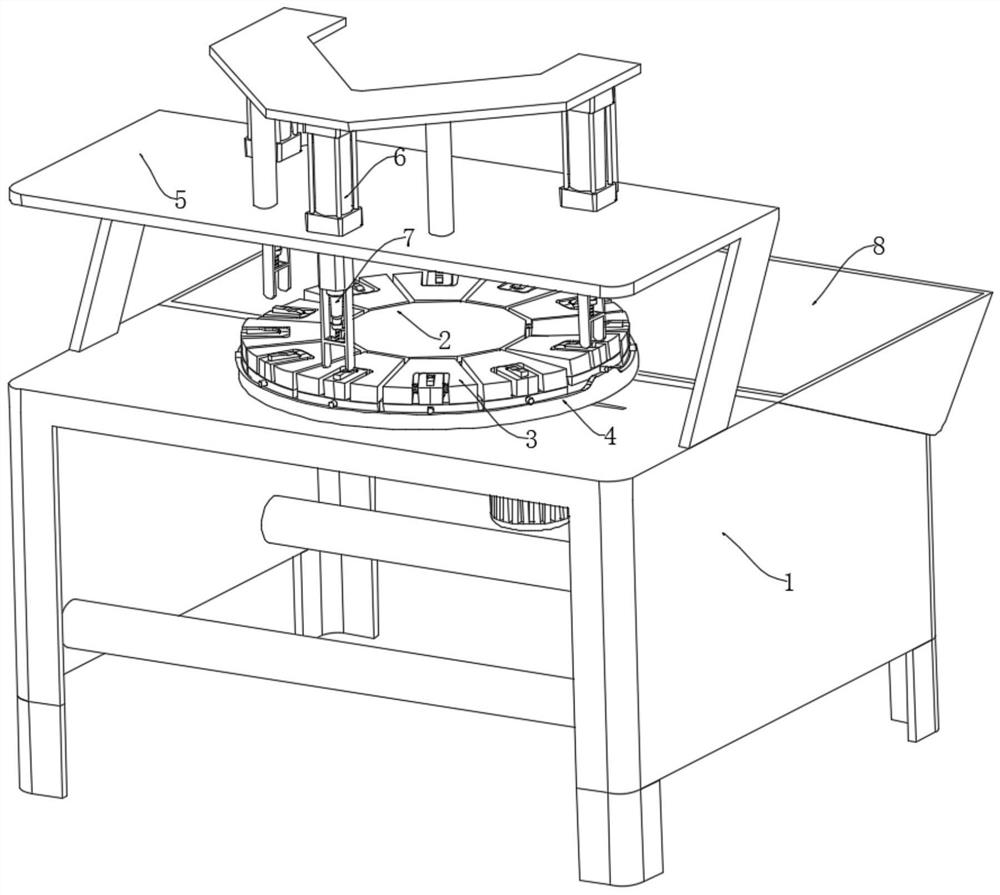

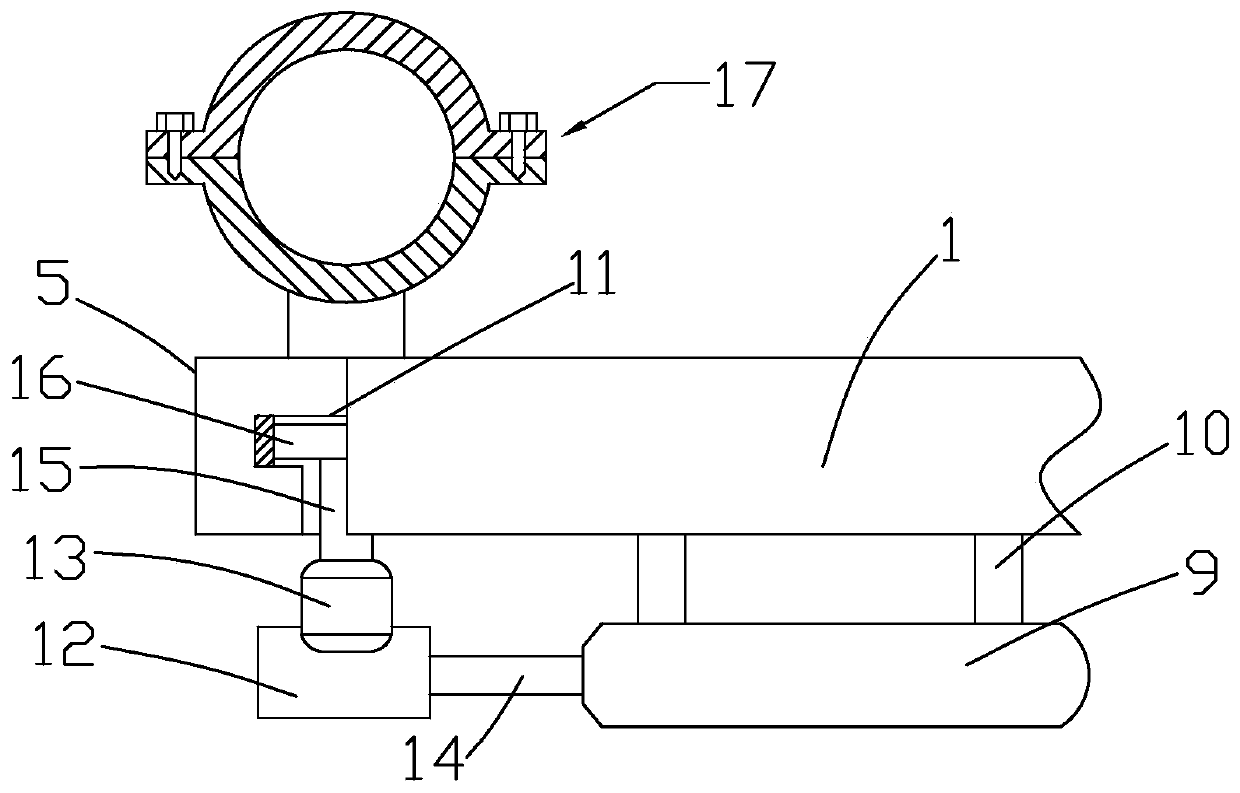

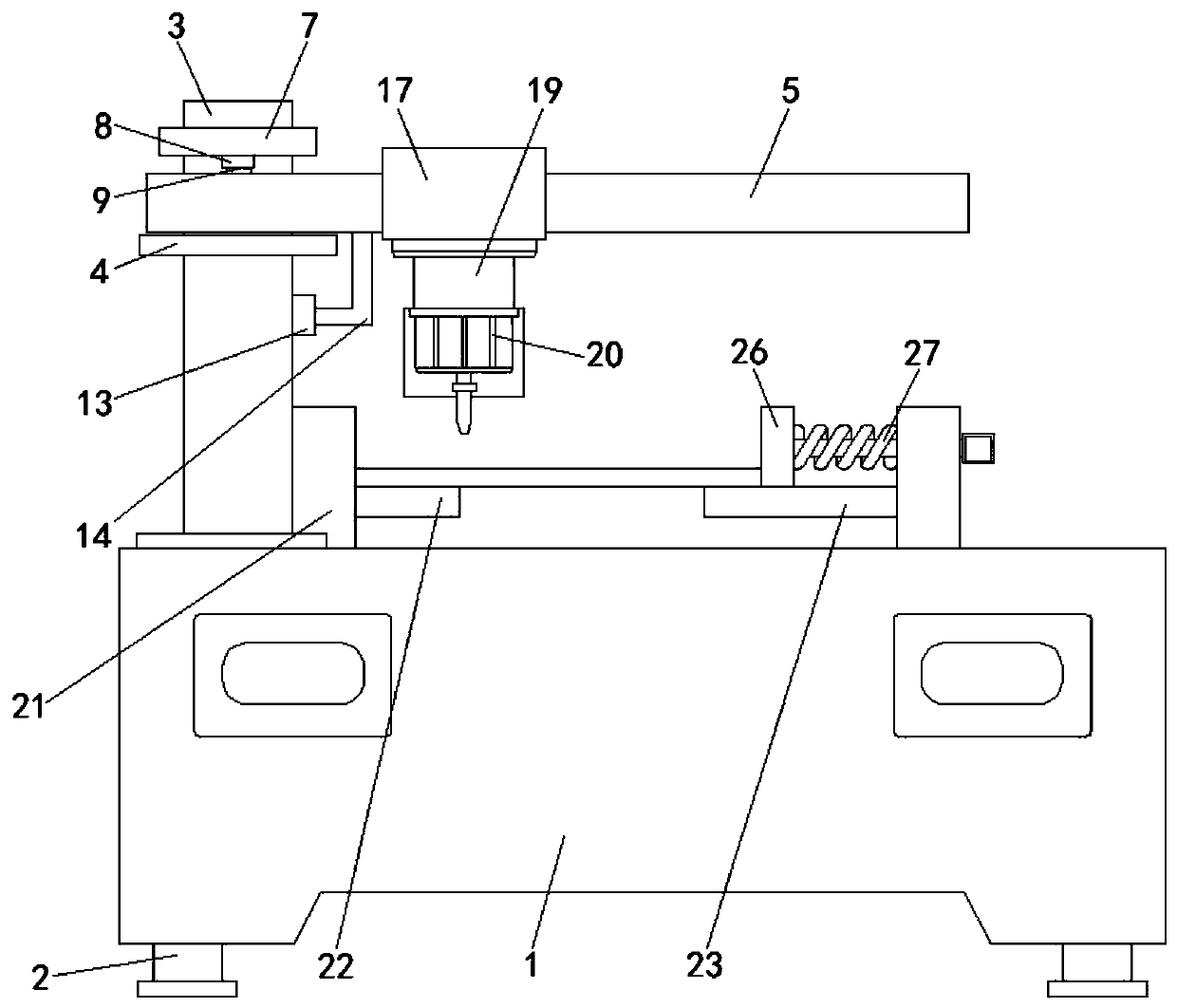

Efficient wall drilling device for construction site

InactiveCN108031899AGuaranteed depthQuality assurancePortable power-driven toolsPortable drilling machinesGear wheelThreaded rod

The invention discloses an efficient wall drilling device for a construction site. The efficient wall drilling device for the construction site comprises a bottom plate, a first mounting plate, a shearing fork type lifting mechanism, a second mounting plate, a first motor, an incomplete gear, a rectangular frame, a suction nozzle, a dust collector, a second motor, a drilling rod, a threaded rod, arotating rod, a second rack, a gear and a third motor, wherein the efficient wall drilling device for the construction site is provided with the shearing fork type lifting mechanism; holes at different heights can be drilled; the adaptability is high; the device is provided with the first motor, the incomplete gear and the rectangular frame; a drill rod is driven to move in the left-right direction by cooperate for drilling; repeated churn drilling is implemented; the depth and quality of drilled holes can be ensured; the drilling effect is improved; the device is provided with the threaded rod and the rotating rod, and the drilling depth can be adjusted; the device is provided with the third motor, the gear and the second rack, by cooperate, a secondary movement device is not required, holes can be drilled directly in the longitudinal direction, and the device is large in drilling range, convenient and rapid, and high in working efficiency.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

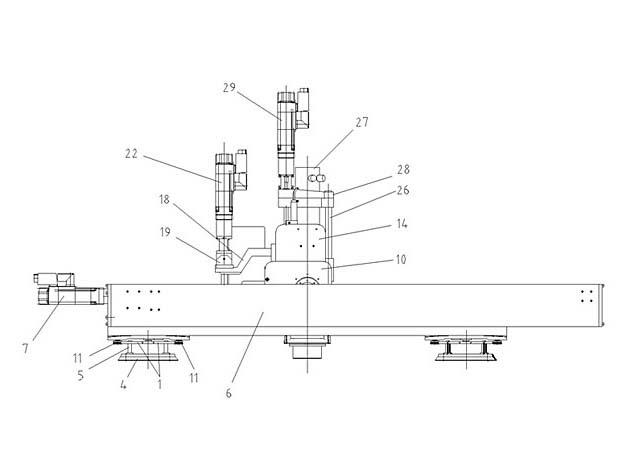

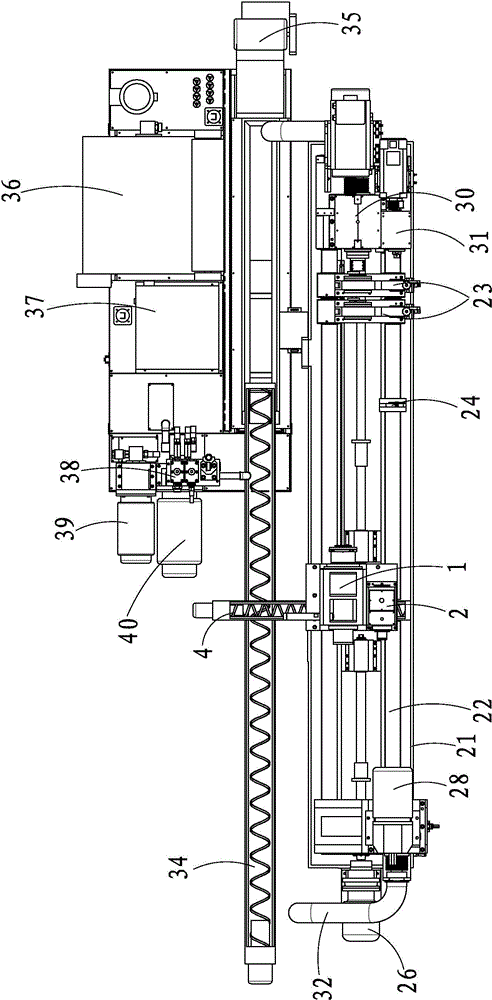

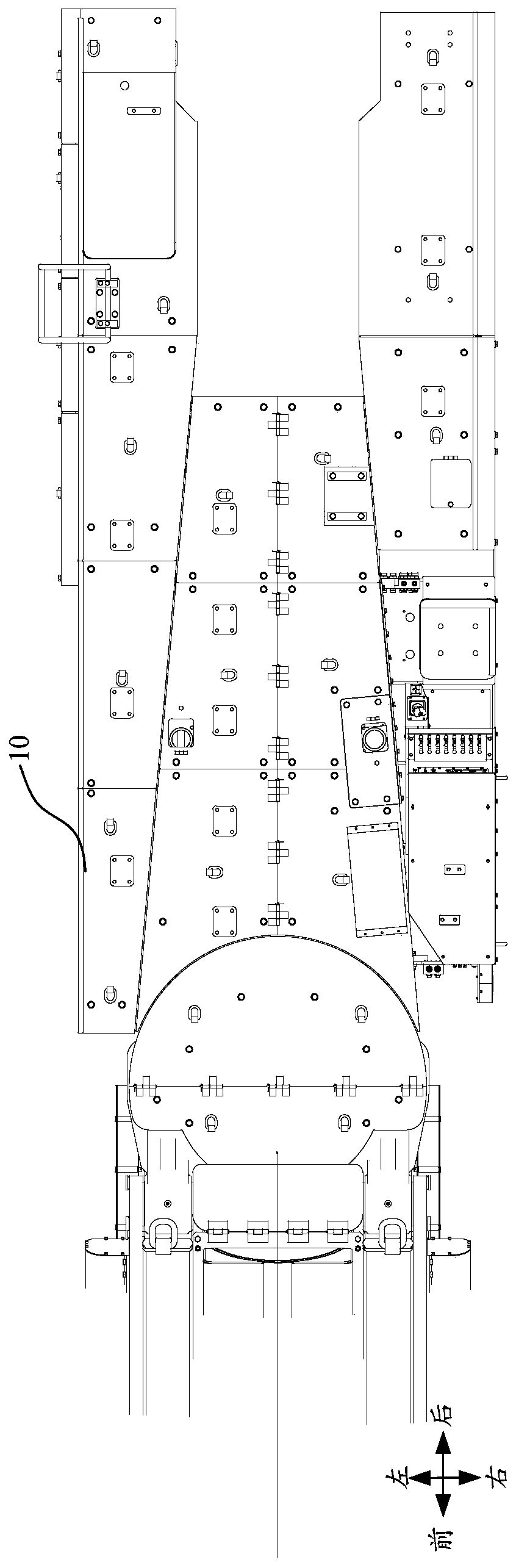

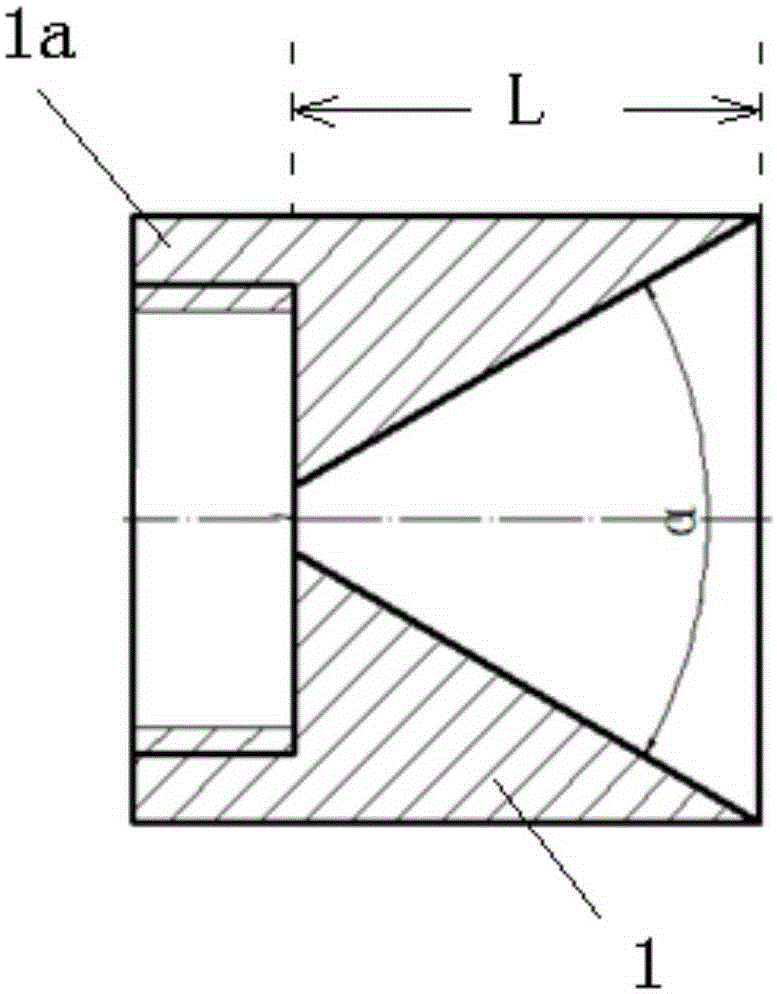

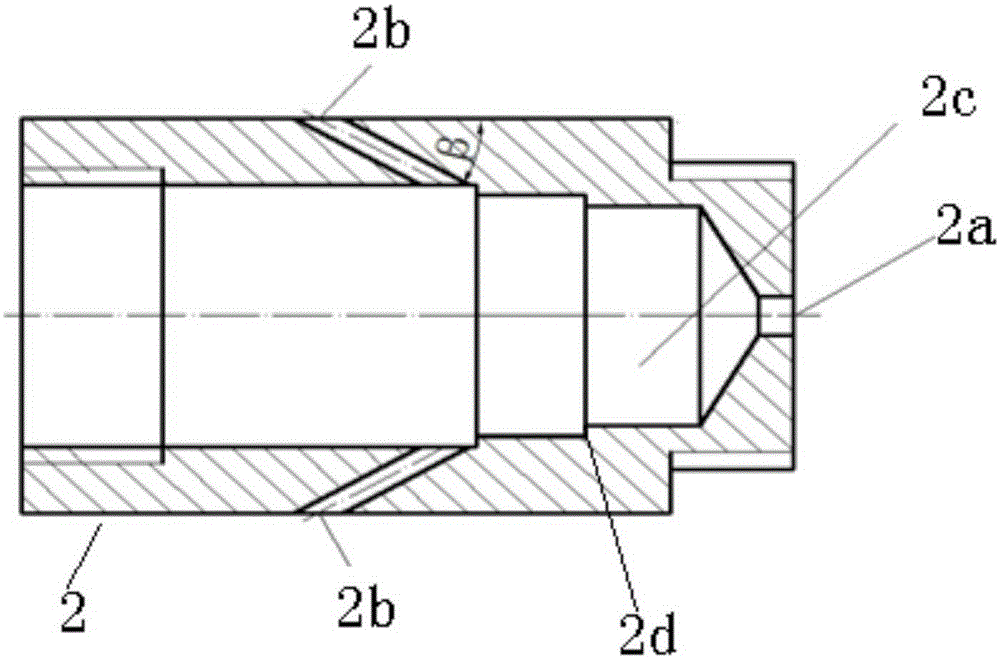

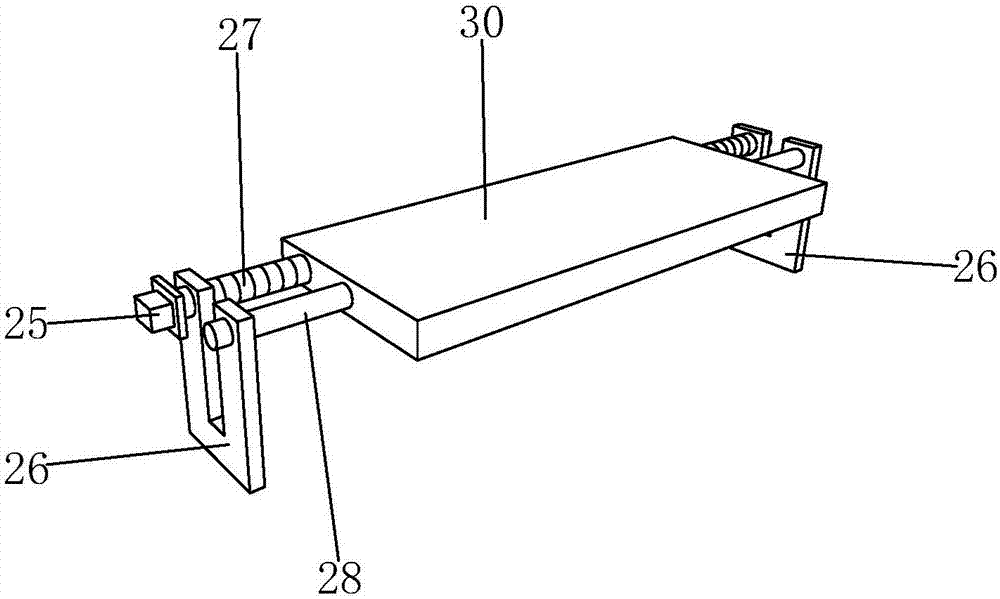

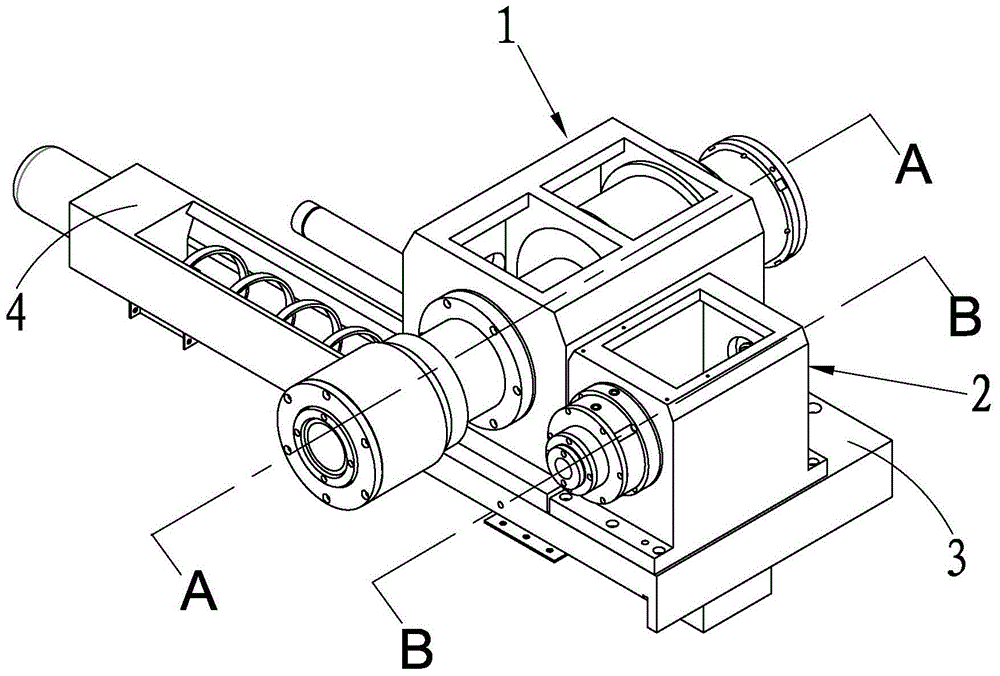

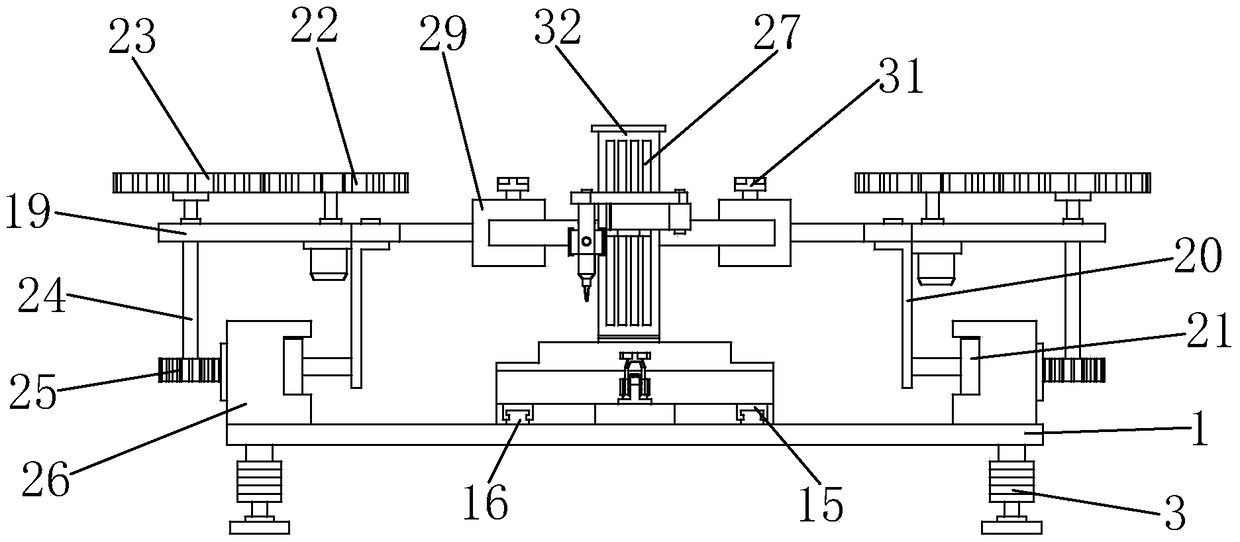

Composite deep hole machine tool

InactiveCN104400060AReduce biasExtended drilling rangeDrilling/boring measurement devicesPositioning apparatusThermodynamicsMachine

The invention relates to a composite deep hole machine tool. The composite deep hole machine tool comprises a machine body, a drilling tool, a driving mechanism which is arranged on the machine body and used for driving the drilling tool to drill a hole, a guiding mechanism, a chippings recovery mechanism which is arranged on the machine body and a cooling filtering mechanism, wherein the drilling tool comprises a BTA drilling rod and a gun drill, which are arranged in parallel, the guiding mechanism comprises a pre-tightening device, oil feeding devices and a guiding frame, the pre-tightening device is arranged on the front part of the machine body in a way of sliding in the longitudinal direction and used for pre-tightening a workpiece, the oil feeding devices are arranged side by side on the machine tool in the lateral direction, the front part of the BTA drilling rod is arranged in the oil feeding device in a penetrating manner, the rear end of the BTA drilling rod is installed on the driving mechanism, the front part of the gun drill is arranged in the guiding frame in a penetrating manner, and the rear end part of the gun drill is installed on the driving mechanism. The BTA drilling rod and the gun drill are arranged on one machine body, so that a machining way of coexistence of the BTA and gun drill is realized, and the drilling range is enlarged; the pre-tightening device is used for pre-tightening the workpiece, so that the deviation of the oil feeding device when in movement can be reduced.

Owner:SUZHOU XINNENG PRECISE MACHINERY

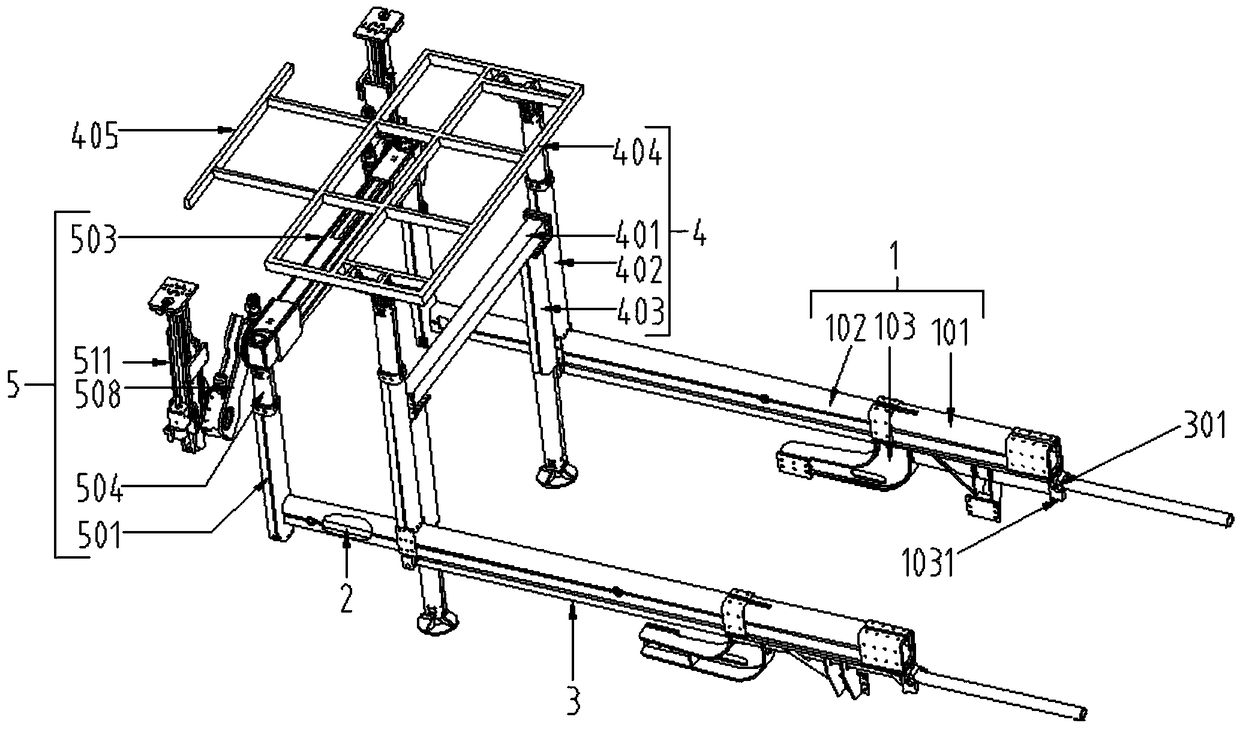

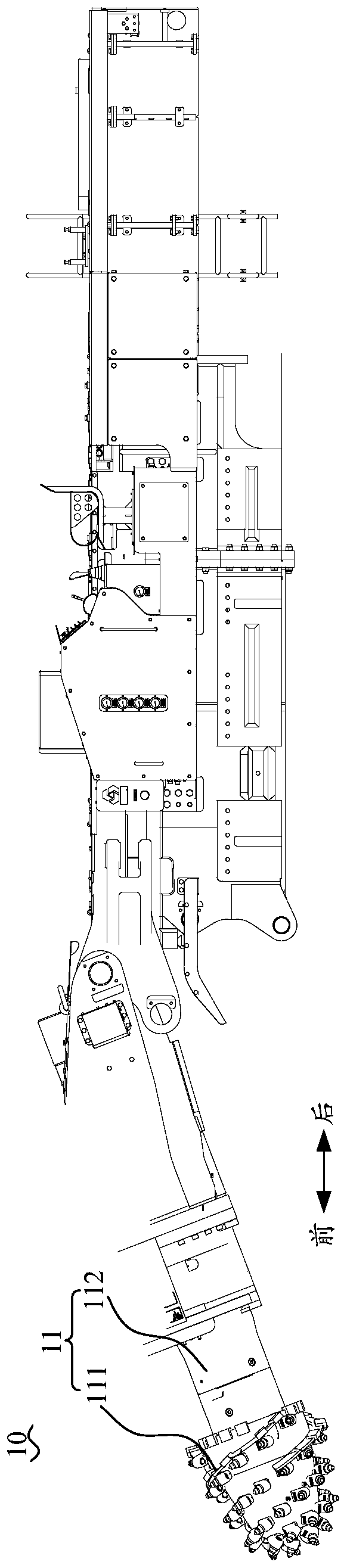

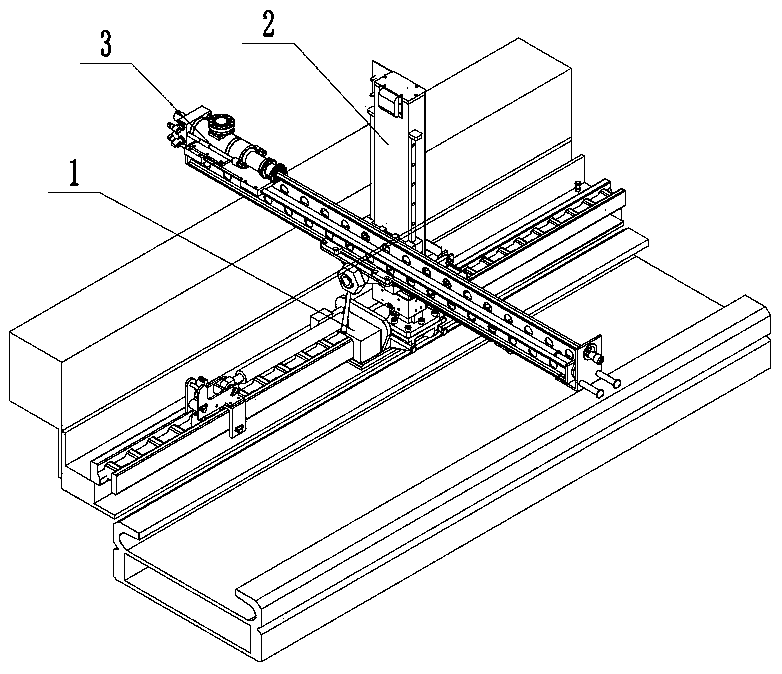

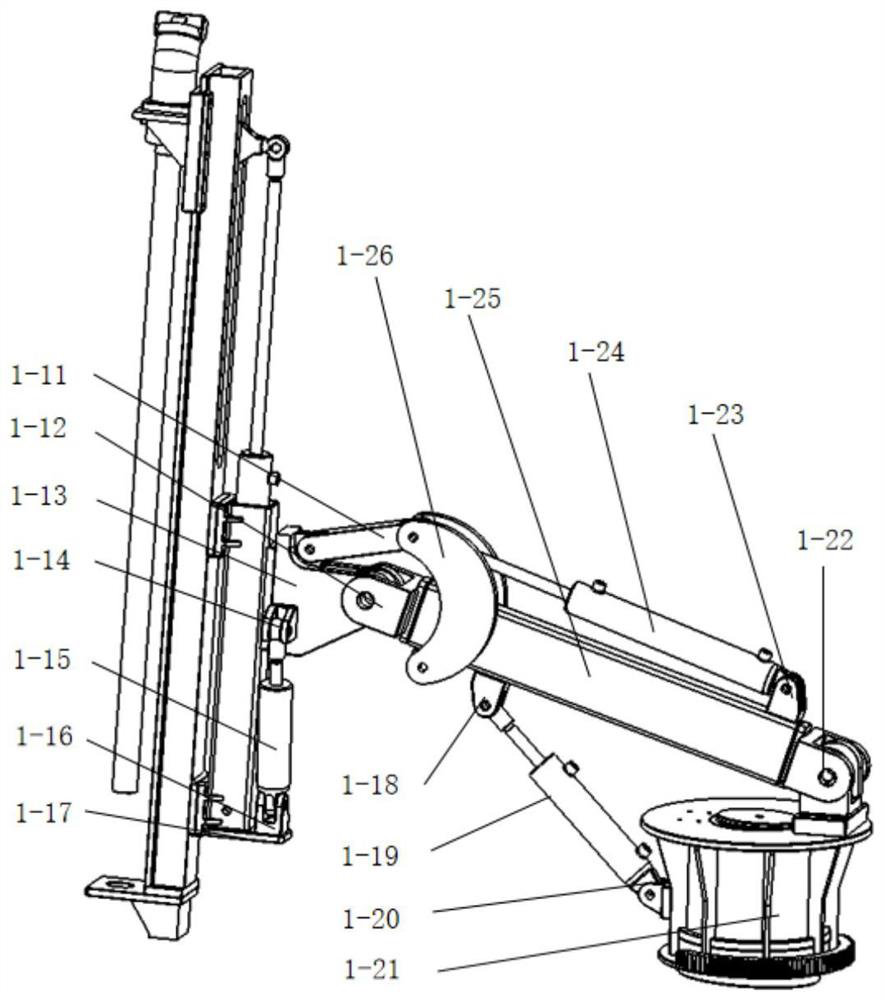

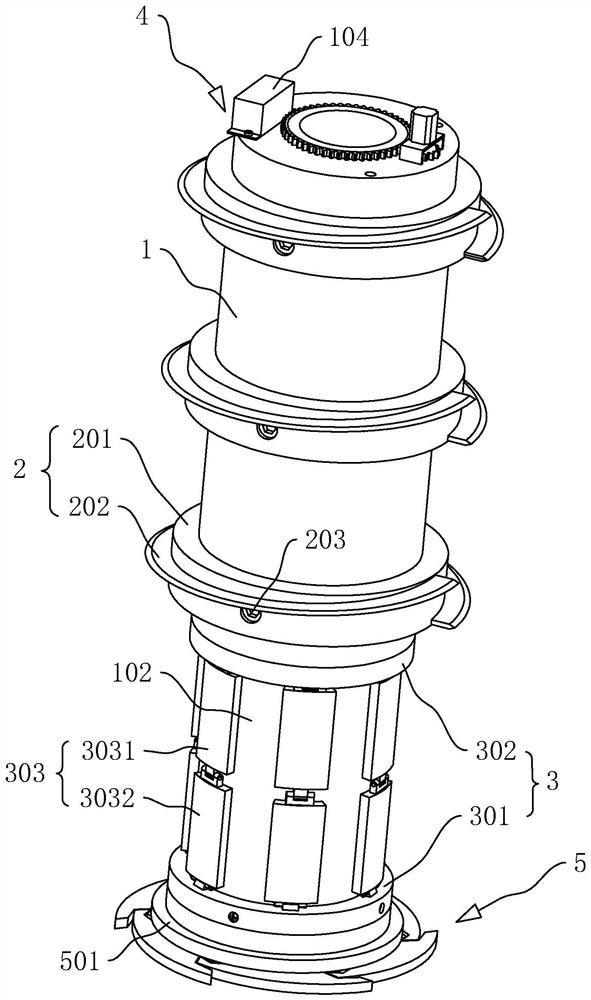

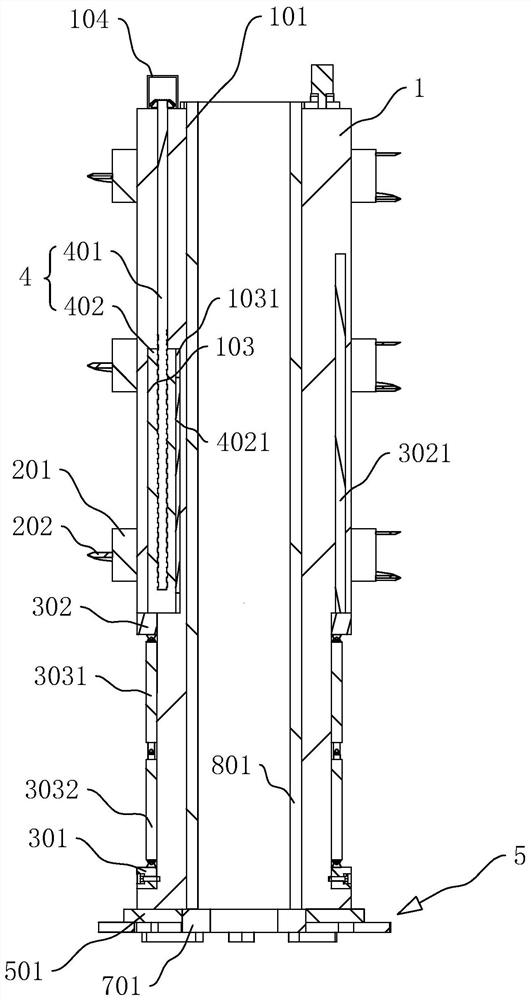

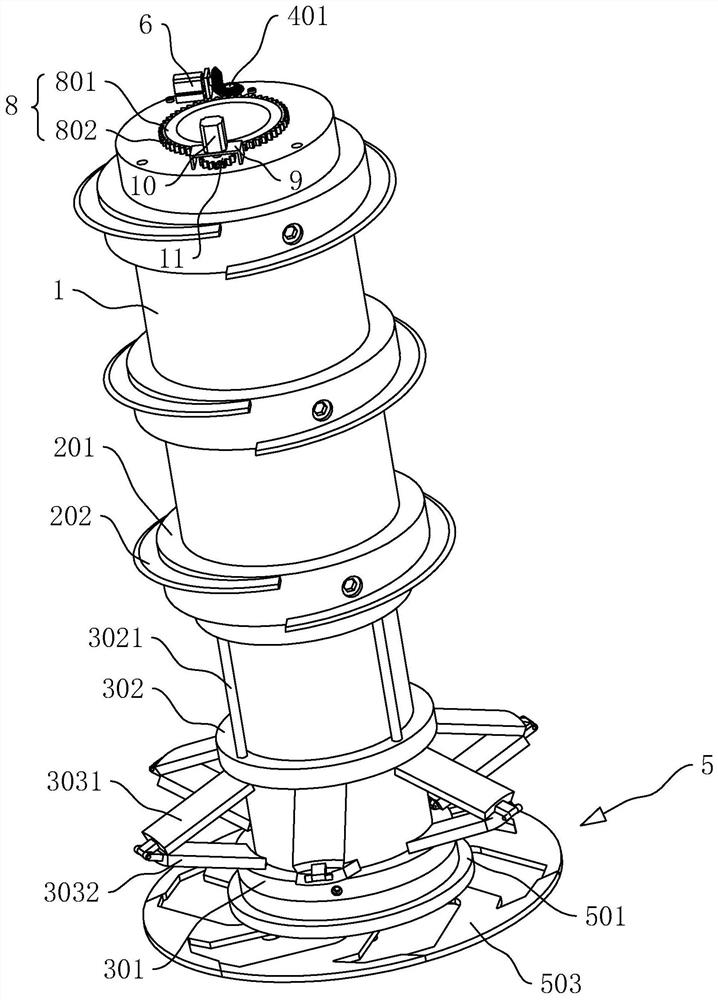

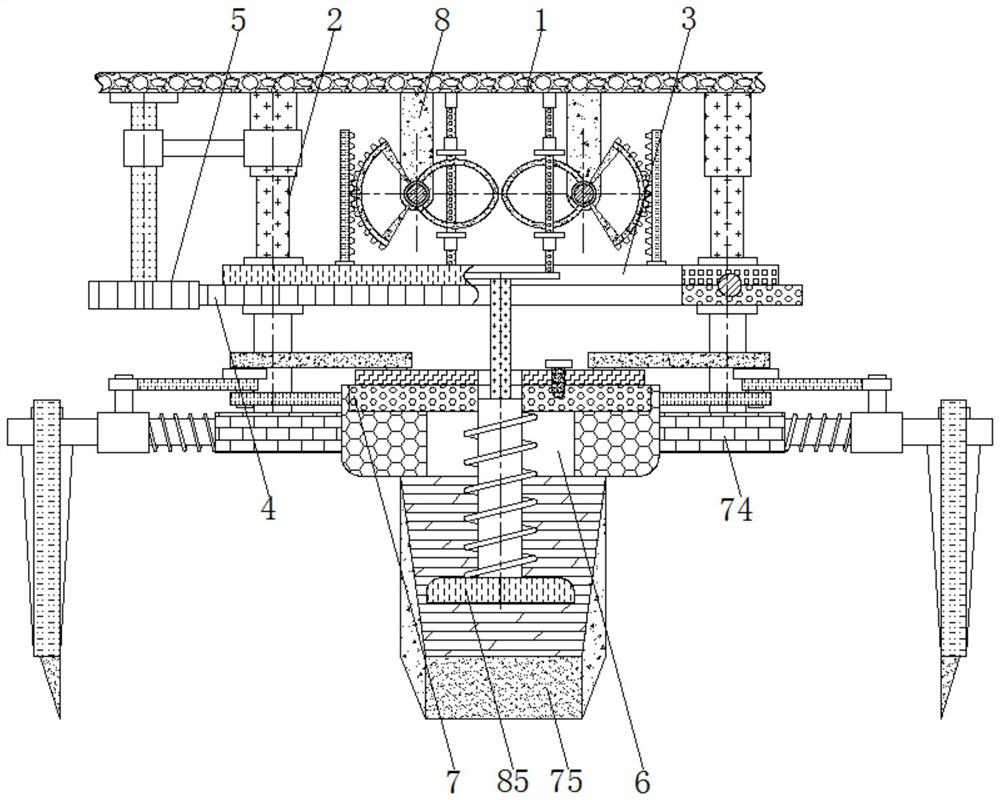

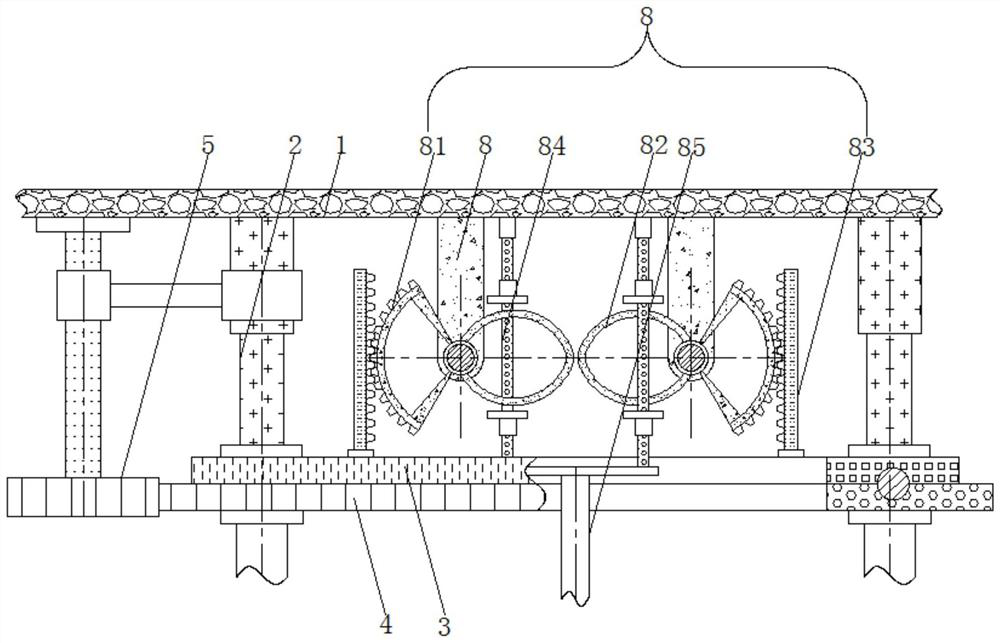

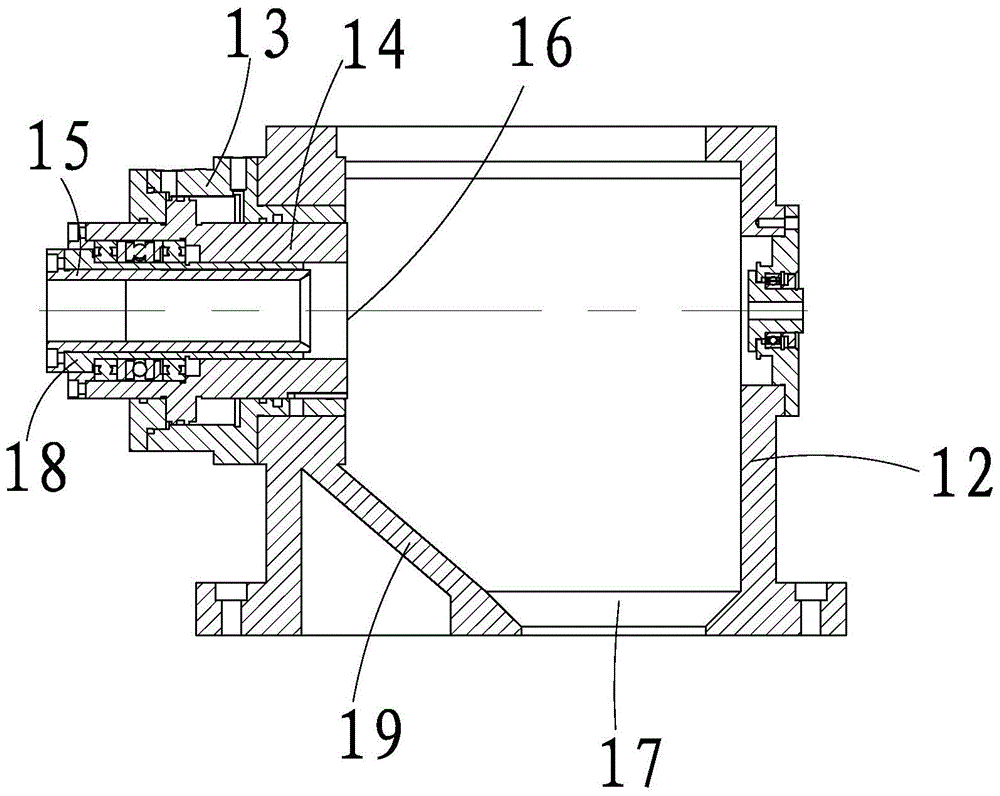

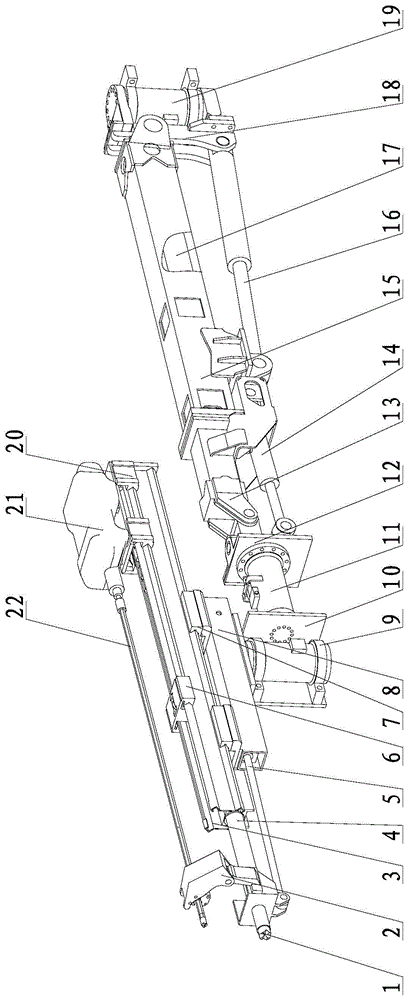

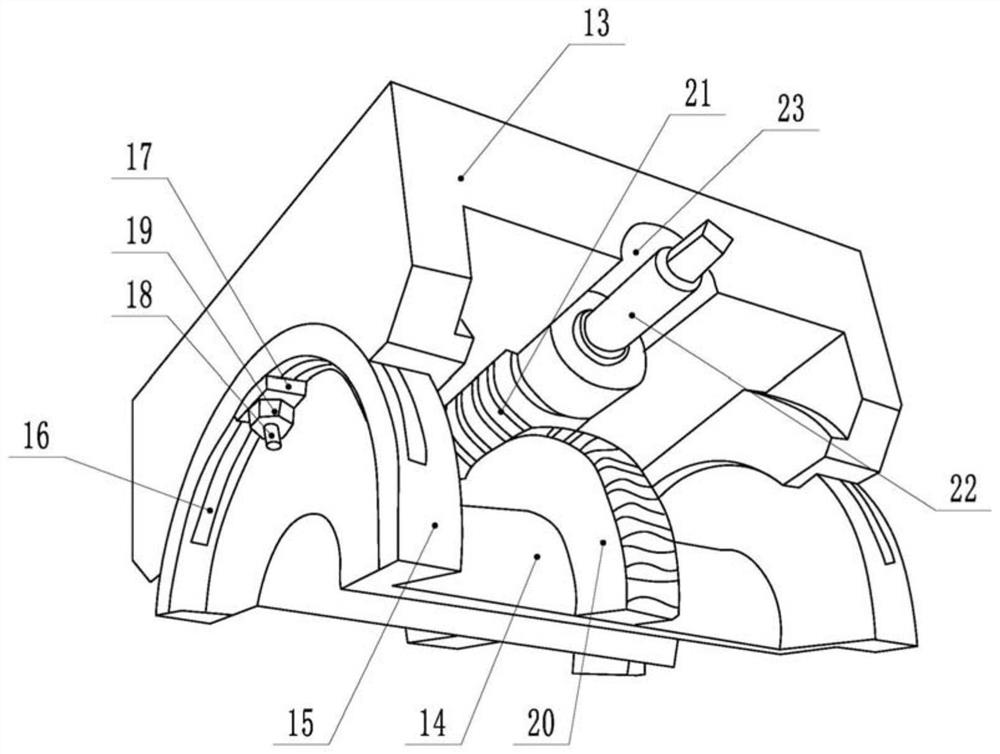

Airborne anchor support mechanism

PendingCN109268046AIncreased drilling rangeFast footageDrilling rodsDerricks/mastsEngineeringUltimate tensile strength

The invention provides an airborne anchor support mechanism comprising a main telescopic arm, a temporary supporting mechanism and a mechanical anchor drilling assembly. The main telescopic arm comprises an outer cylinder and an inner cylinder, and the lower side of the outer cylinder is fixedly connected to a base frame. The inner cylinder is in sliding connection in the outer cylinder, and the upper side of the inner cylinder is fixedly connected with the temporary supporting mechanism. The mechanical anchor drilling assembly comprises an 'L'-shaped bracket. The 'L'-shaped bracket comprisesa vertical cylinder and a horizontal cylinder. The vertical cylinder and the horizontal cylinder are vertically connected, and the horizontal cylinder is in sliding connection in the inner cylinder. The inner cylinder is provided with a row spacing adjustment cylinder, one end of the row spacing adjustment cylinder is hinged to the inner cylinder, and the other end is hinged to the horizontal cylinder. The airborne anchor support mechanism can increase the drilling operation range, and improve the driving speed. The temporary supporting mechanism and the mechanical anchor drilling assembly areseparated, so that the temporary supporting can always effectively support the roadway stroke during multi-row construction operation, the operation safety is improved, the equipment utilization is improved, and the labor intensity is reduced.

Owner:山东浩吉矿业装备有限公司

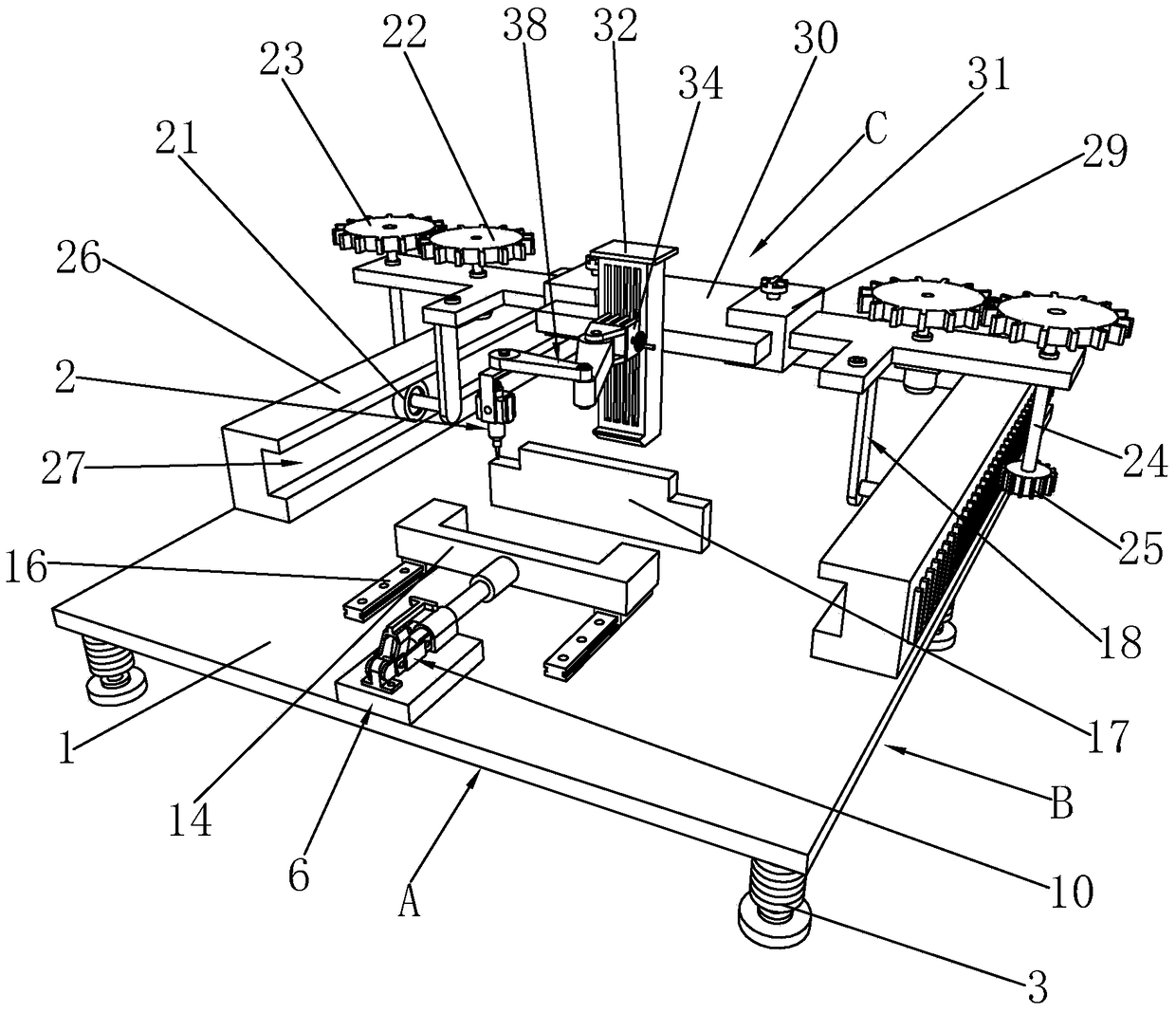

Drilling device used for decoration board

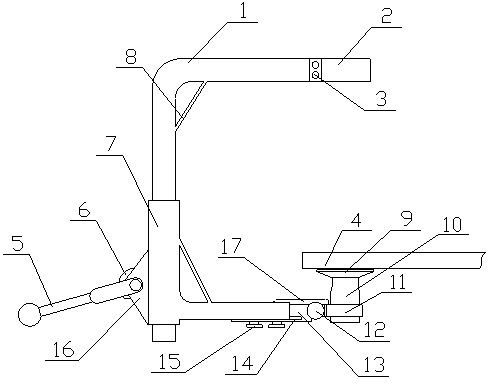

ActiveCN105459217AImprove stabilitySimple structureStationary drilling machinesEconomic benefitsMechanical engineering

The invention discloses a drilling device used for a decoration board. The drilling device comprises a rack and a drilling mechanism. Moving mechanisms are arranged on the rack. U-shaped clamping blocks are fixed to one sides of the moving mechanisms. A work platform is arranged between the U-shaped clamping blocks. A multi-groove base is arranged on the work platform in the longitudinal direction. The multi-groove base is connected with a sliding seat in a sliding manner. A rotating mechanism is fixed to the sliding seat. An L-shaped connecting block is arranged on the rotating mechanism. A drilling mechanism is arranged on the L-shaped connecting block. A fixed base is arranged on the rack and is connected with a clamping mechanism. A baffle is arranged on the rack. According to the drilling device used for the decoration board, the combination of the moving mechanisms and the rotating mechanism is used, the drilling device stretches and contracts freely and can rotate left and right by 180 degrees, the drilling range is greatly enlarged, and the drilling technology can be conducted on the decoration board comprehensively. The structure is simple, practicability is high, manufacturing cost is low, and economic benefits are obvious.

Owner:GUANGZHOU SNIMAY HOME FURNITURE CO LTD +1

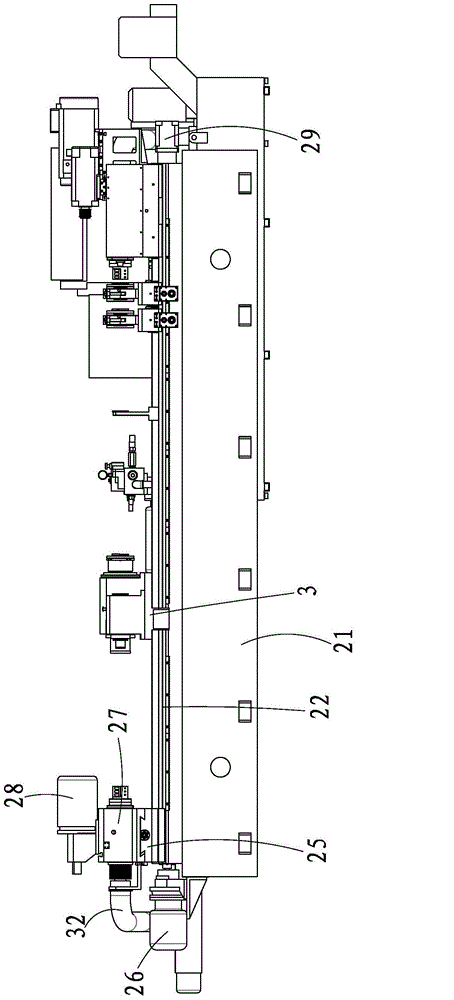

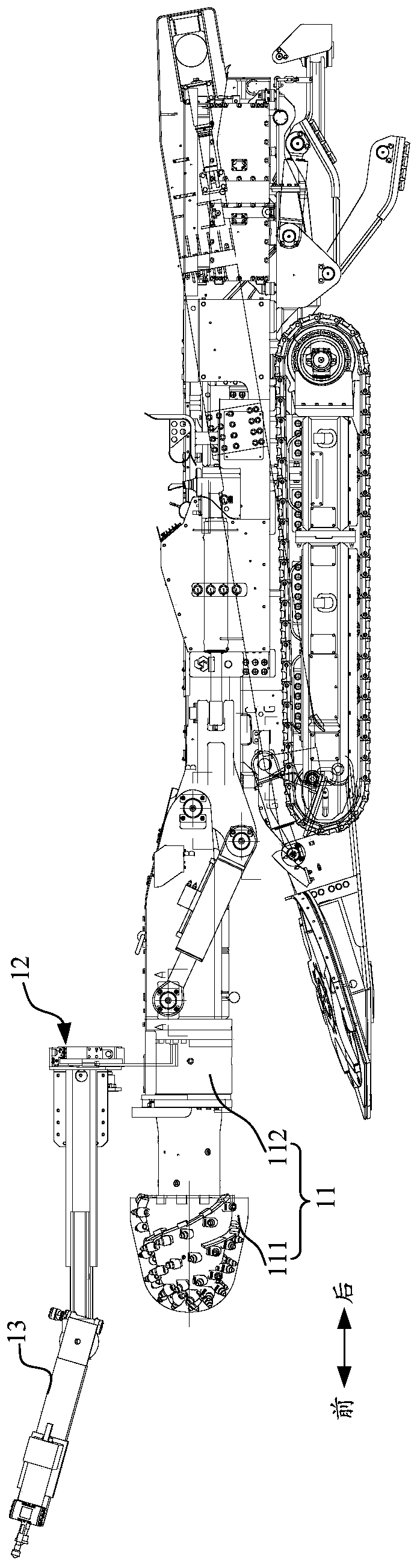

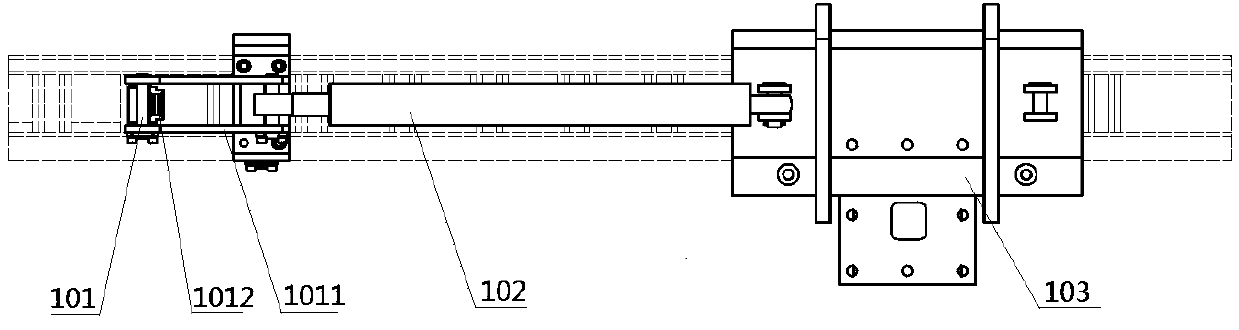

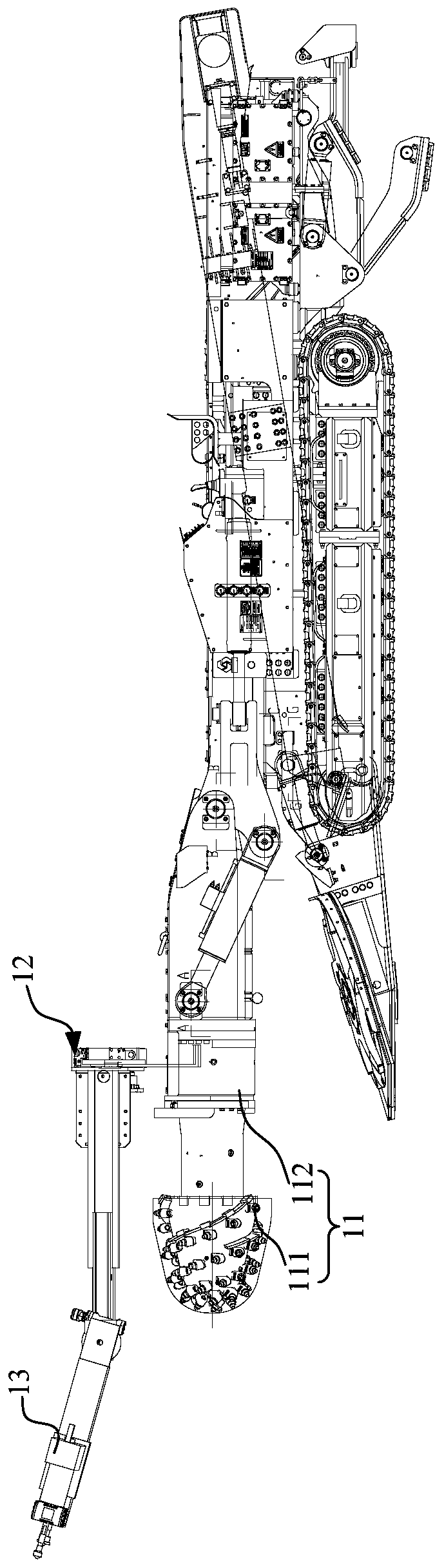

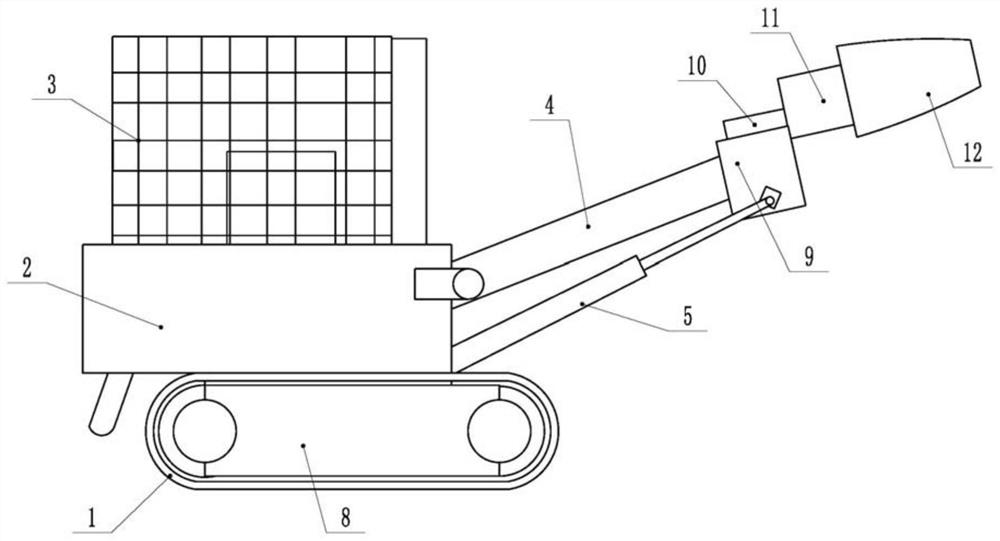

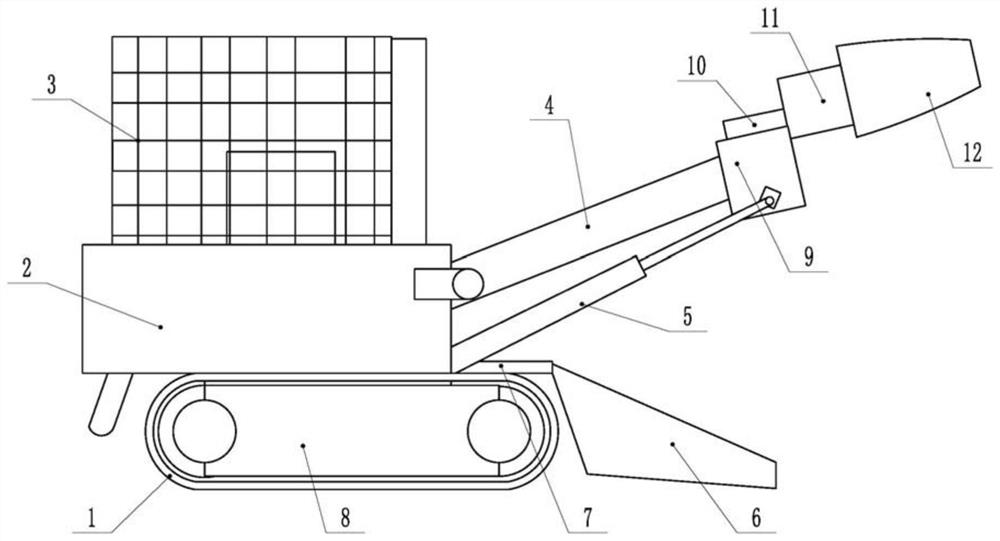

Excavating and drilling machine

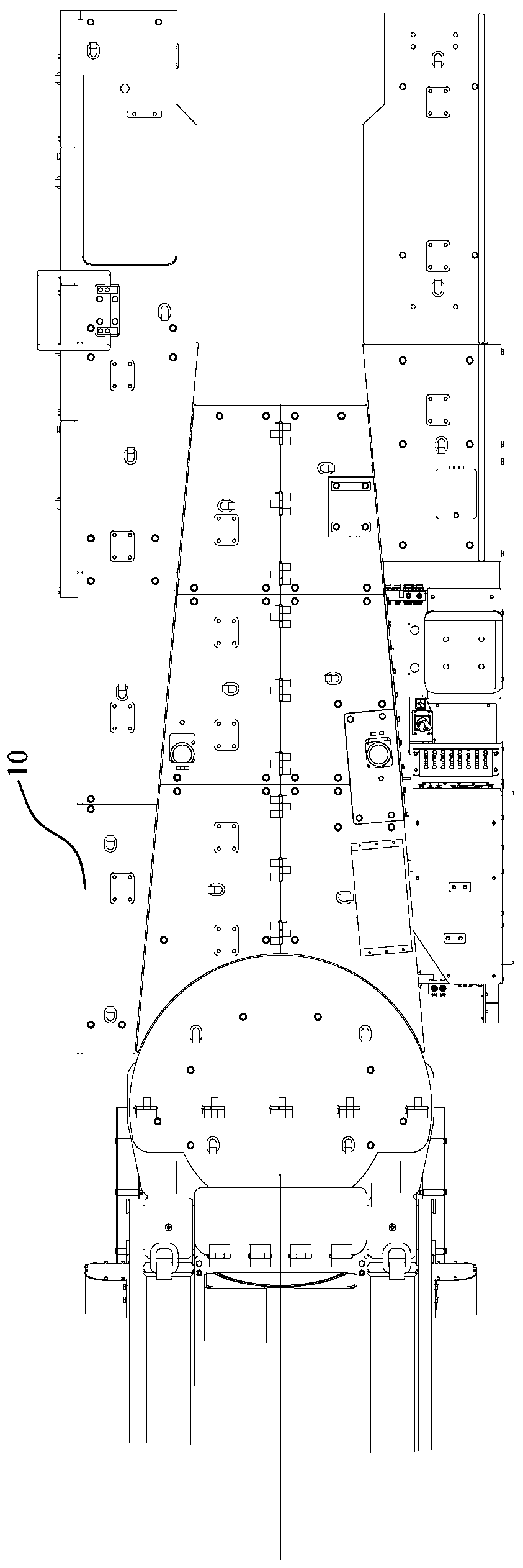

PendingCN110529110AExtended drilling rangeExpand the scope of activitiesDerricks/mastsSlitting machinesDegrees of freedomEngineering

The invention provides an excavating and drilling machine which comprises an excavating part, a sliding rail assembly and a drilling machine part, wherein the excavating part comprises a cutting arm and a cutting head positioned at the front end of the cutting arm and connected with the cutting arm; the sliding rail assembly is mounted on the cutting arm, and comprises a first rail; an inclined angle is formed between the first rail and the excavating part; and the drilling machine part is connected with the first rail in a sliding manner, and slides along the first rail to be enabled to moverelative to the excavating part. According to the excavating and drilling machine provided by the invention, the drilling machine part slides along the first rail, so that the drilling machine part moves relative to the excavating part; the degree of freedom of the movement of the drilling machine part relative to the excavating part is released through the first rail, for example, the first railspans the left side and the right side of the excavating part, so that the drilling machine part can move between the left side and the right side of the excavating part; and compared with a scheme that an existing drilling machine part only depends on the movement of an excavating part to move, the drilling machine part in the scheme is more flexible, and the drilling range of the drilling machine part is further increased.

Owner:SANY HEAVY EQUIP

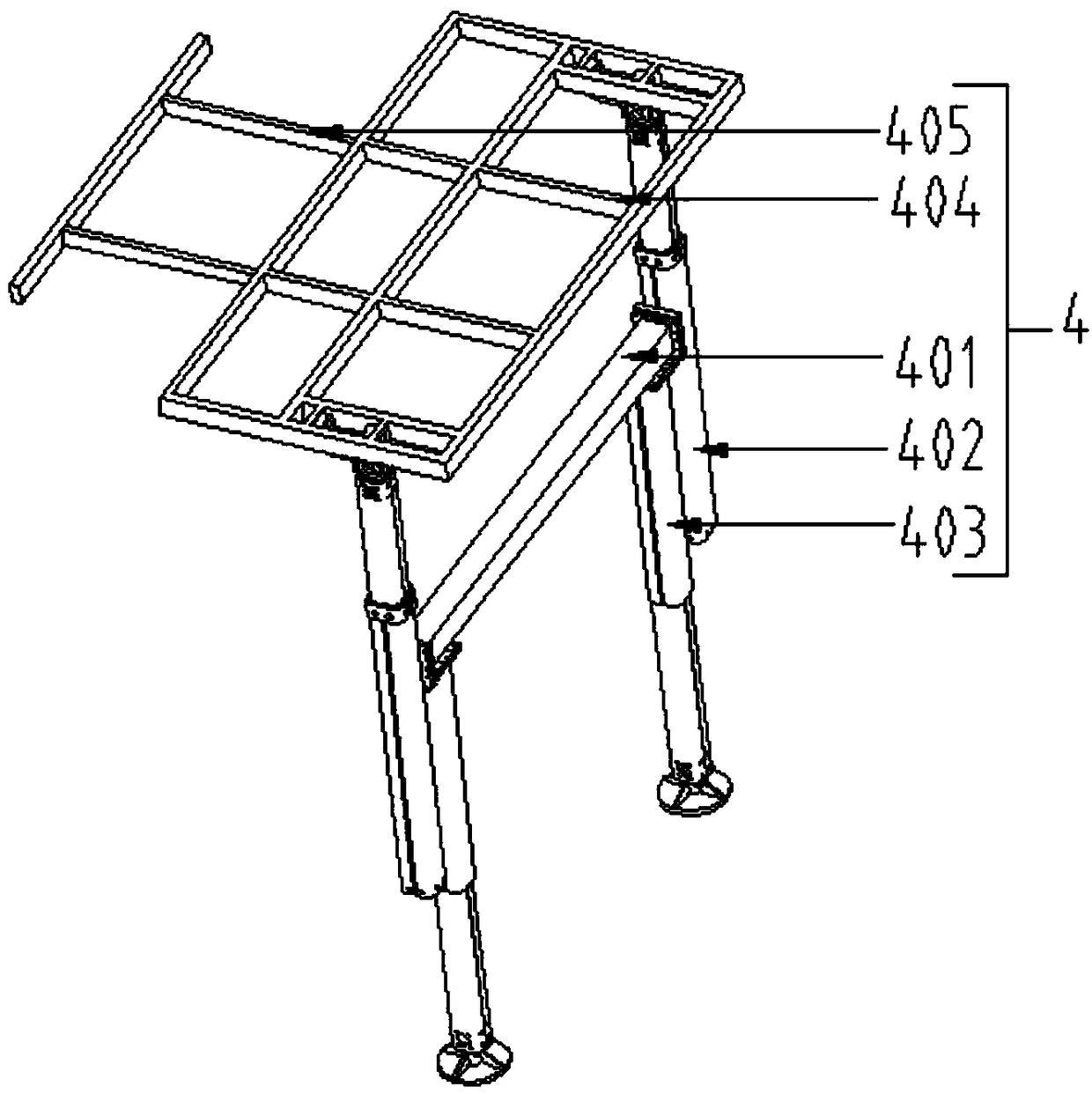

Hydraulic fully-mechanized mining fault rock drilling equipment

ActiveCN109779626AAchieve horizontal movementIncrease vertical lift distanceDerricks/mastsDriving meansHydraulic pumpEngineering

The invention relates to the technical field of rock drilling, in particular to hydraulic fully-mechanized mining fault rock drilling equipment. The equipment comprises a walking part, a two-stage lifting part, a pushing part and a hydraulic pump station, the walking part is fixed to a toothed rail of an underground conveyor, the two-stage lifting part is fixed to the walking part through screws,the pushing part is connected with the two-stage lifting part, and the hydraulic pump station provides power for the walking part, the two-stage lifting part and the pushing part. The equipment is convenient to carry, mount and dismount, is suitable for a working section with the length of 2.5m or above, can be quickly withdrawn out of a working area after drilling and blasting, and does not affect propelling of a coal mining machine.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

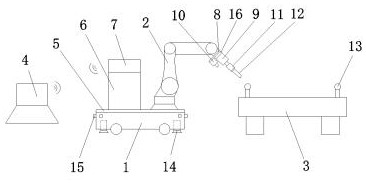

Industrial robot automatic drilling system and using method

InactiveCN112157284ALow costIncrease processing costManipulatorBoring/drilling componentsWireless controlControl engineering

The invention discloses an industrial robot automatic drilling system and a using method. The industrial robot automatic drilling system comprises an automatic guiding trolley, an industrial robot, amachining platform and a data processing platform, wherein a bottom plate is installed at the top of the automatic guiding trolley, and the industrial robot is installed on the right side of the top of the bottom plate; a connecting plate is installed at the tail end of a sixth shaft of the industrial robot, a motor and a camera are installed on the connecting plate, the output end of the motor isconnected with one end of a chuck, and the other end of the chuck clamps a drill bit; the data processing platform is connected with a PLC in a wireless control mode; and at least four reference balls are installed on the side edge of the top of the machining platform. The automatic guiding trolley drives the industrial robot to move, the drilling range is enlarged, and flexible machining is achieved; and the reference balls are measured at different positions through the camera, the position relation between the drill bit and a workpiece is calibrated, it is guaranteed that when the robot islocated at different positions, the drill bit and the workpiece are located in a unified coordinate system, the workpiece drilling machining precision is guaranteed, the efficiency is high, the yieldis high, and the cost is low.

Owner:蒙美兰

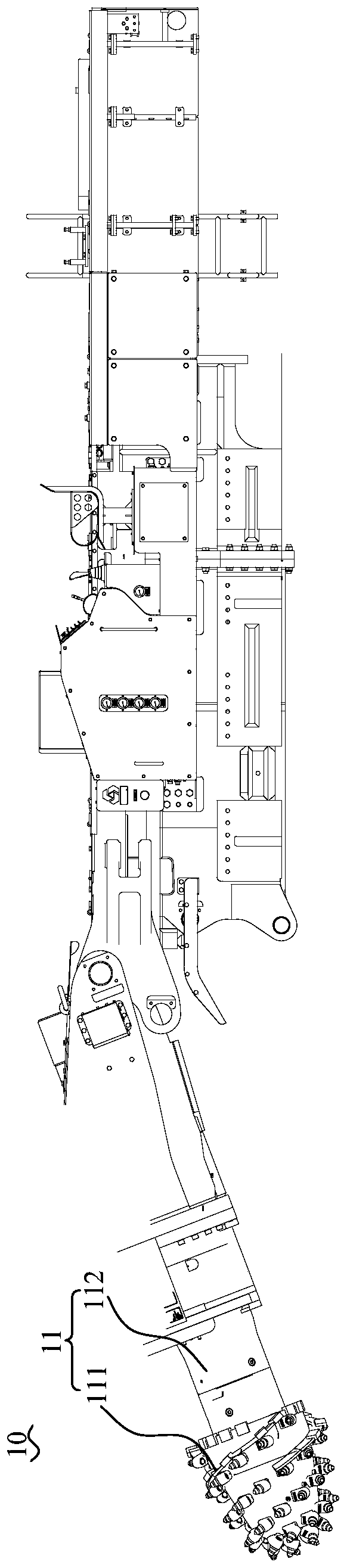

Variable-amplitude movable deep sea sampling drilling machine

PendingCN112796663AExtended drilling rangeRealize automatic obstacle avoidanceDerricks/mastsCore removalEngineeringMechanical engineering

The invention provides a variable-amplitude movable deep sea sampling drilling machine. The variable-amplitude movable deep sea sampling drilling machine comprises a variable-amplitude device, a visual device, a hydraulic device, a control device and a walking vehicle, wherein the visual device is installed on the walking vehicle and comprises a light source, a camera and a lens; the variable-amplitude device is installed at the front end of the walking vehicle and comprises a drilling machine body, a pitching mechanism, a rotary disc and a power head b; the drilling machine body comprises a power head a, a sliding frame, a drilling frame, a drilling rod, a feeding oil cylinder, an oil cylinder fixing cavity and a drilling rod supporting base; and the pitching mechanism comprises a connecting rod a, a fixed hinged support, a movable arm oil cylinder, a drilling frame oil cylinder, a movable arm and a connecting rod b. Drilling sampling with the pitching angle ranging from 0 degree to 90 degrees and drilling sampling with the azimuth angle ranging from 0 degree to 180 degrees can be achieved, and the drilling range of the sampling drilling machine is enlarged; the visual device is introduced, and automatic obstacle avoidance and path planning of the sampling drilling machine on the seabed can be achieved; and the drilling frame can deflect left and right, the drilling angle is adjusted, and the variable-amplitude movable deep sea sampling drilling machine adapts to the severe environment with the uneven seabed bottom.

Owner:HUNAN UNIV OF SCI & TECH

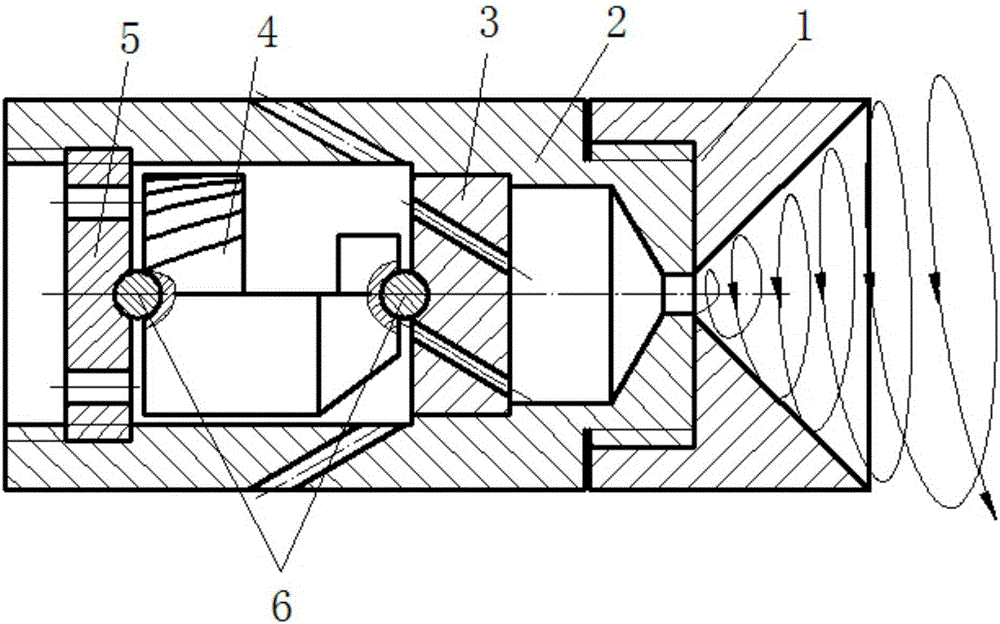

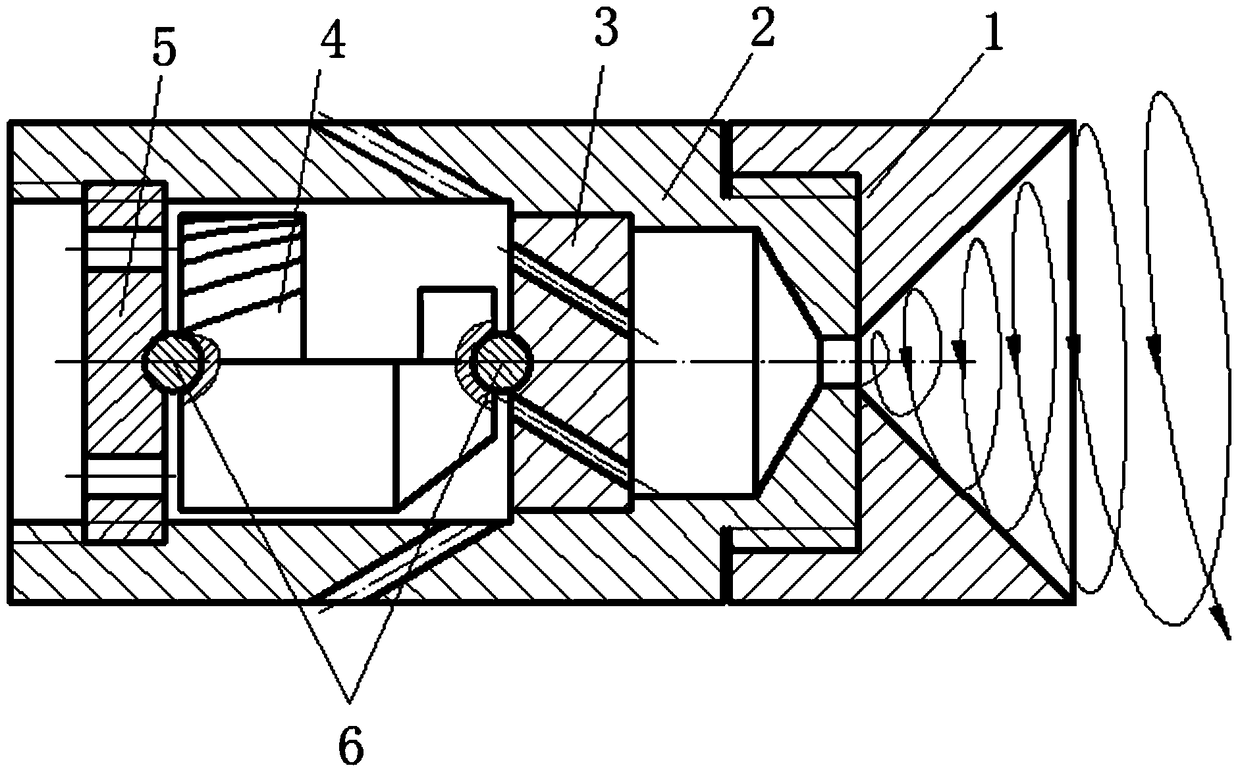

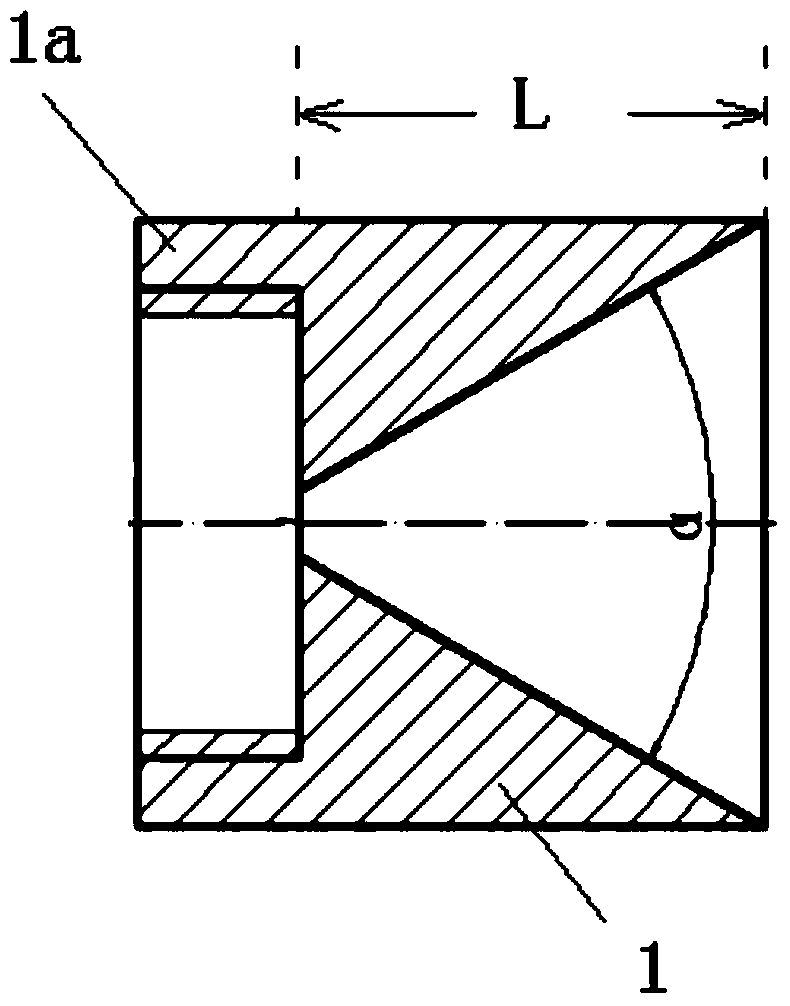

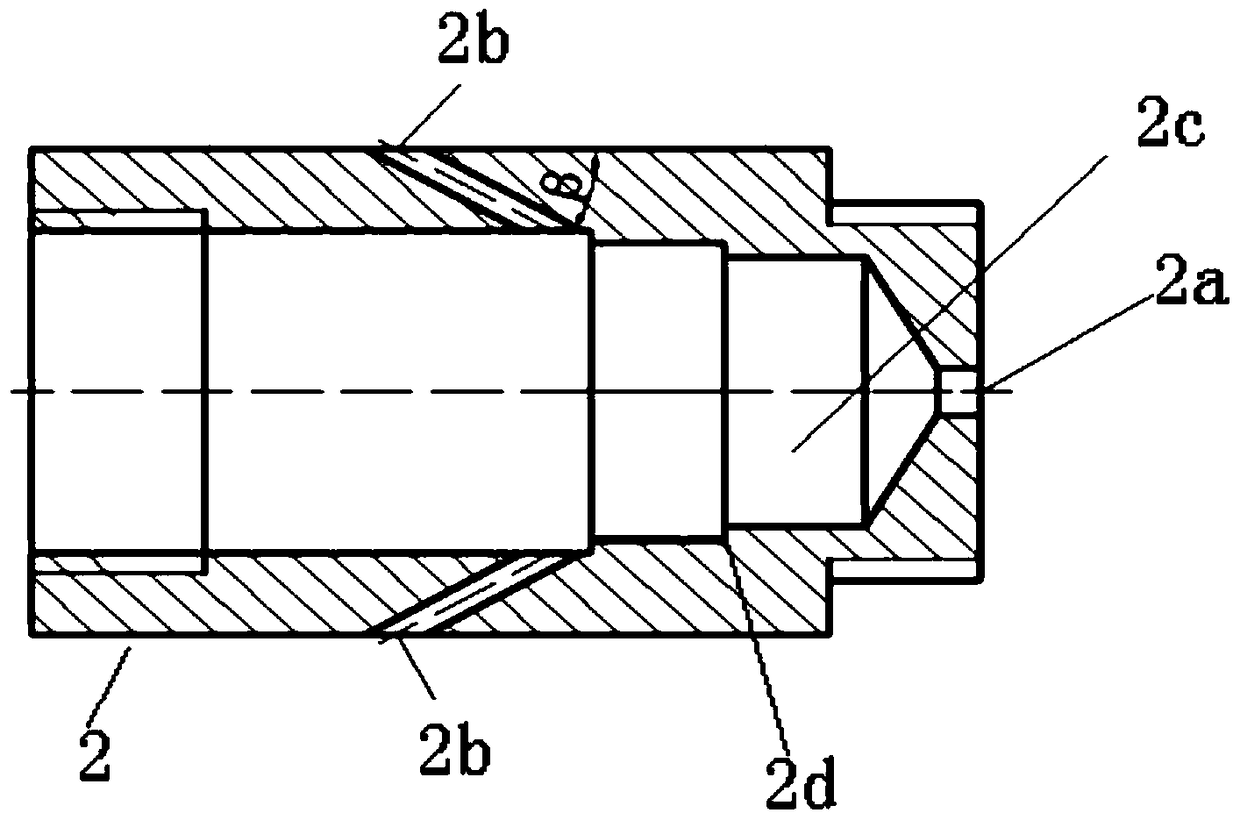

Vibration-type rotary-jetting drill bit

ActiveCN106545298AExtended drilling rangeExpand the attack surfaceDrill bitsLiquid/gas jet drillingImpellerWater flow

The invention discloses a vibration-type rotary-jetting drill bit, pertaining to the field of jetting drill bits. The vibration-type rotary-jetting drill bit at least comprises an expansion section, a drill bit body, an impeller, an eccentric motor, a baffle plate, and bearings. The right end of the drill bit is connected with the expansion section. The drill bit is internally provided with the impeller, the eccentric motor, and the baffle plate in order from the right to the left. The left end of the impeller is connected with a right end of the eccentric motor through one bearing. The left end of the eccentric motor is connected with a right end of the baffle plate through the other bearing. The baffle plate is in threaded connection with the drill bit body. The drill bit body and the surface of the expansion section are inlaid with diamonds. The additional arrangement of the eccentric motor enables the drill bit to vibrate by circumference and helps increase the range of the drill bit. Due to the additional arrangement of the impeller, more high-voltage water flows rotate, the hitting surface of jetting flow is broadened and drilling efficiency is increased. Bu additionally arranging the expansion section, service lifetime of the drill bit is prolonged and the rock breaking surface by jet flows is increased. By inlaying the diamonds on the surface of the drill bit, the effects of mechanically breaking rocks and shaping hole walls are achieved.

Owner:PETROCHINA CO LTD

Drilling device for laminated glass production

InactiveCN106956371AGuaranteed to collect completelyImprove work efficiencyWorking accessoriesFine working devicesElectric machineryWorking environment

The invention discloses a drilling device for the production of laminated glass, which comprises a working platform, on which a driving mechanism, a screw mechanism and a fixing mechanism are respectively arranged, and a supporting block is arranged on the screw mechanism and the fixing mechanism, and the supporting block There is a storage table between them, a receiving box is movably connected between the L-shaped support parts, a sliding seat is provided on the driving mechanism, a support frame is provided on the sliding seat, a stepping motor is provided on the top of the supporting frame, and the stepping motor and the A first screw is provided between the sliding seats, a fixed rod is provided on the sliding seat, a support plate is provided between the fixed rod and the first screw, a drilling motor is provided on the support plate, and a drilling shaft is connected to the drilling motor. One end of the drilling shaft is provided with a drill piece, and drill teeth are distributed around the bottom of the drill piece. The invention has the advantages of simple structure, strong flexibility, large drilling range, and can complete rows of drilling in the horizontal direction, with high working efficiency, simple collection of waste materials, and protection of the working environment.

Owner:嵊州市赫利玻璃制品有限公司

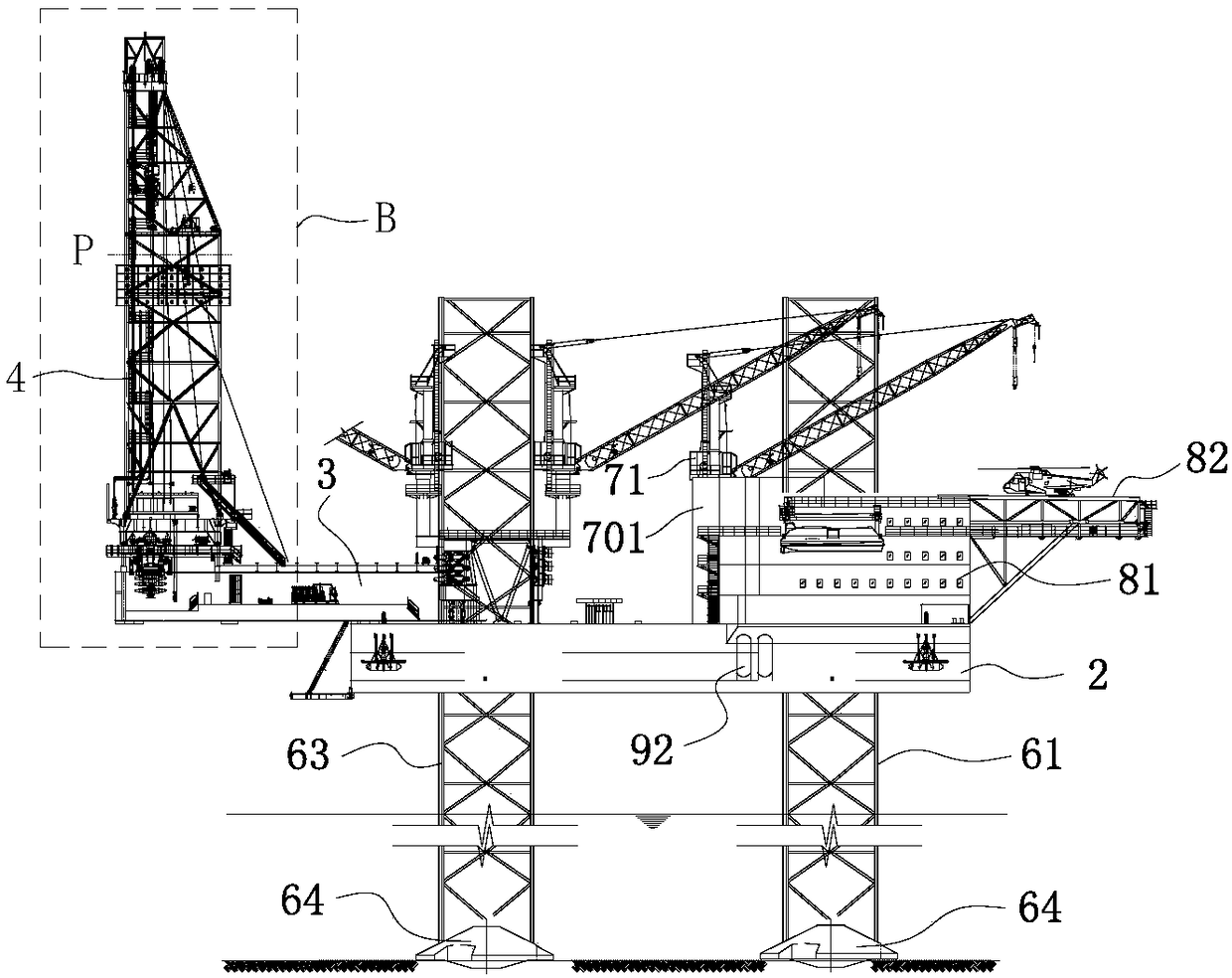

Self-lifting type drilling platform

ActiveCN108691307AExtended drilling rangeExpand the scope of workArtificial islandsUnderwater structuresTime historyCantilever

The invention provides a self-lifting type drilling platform. The self-lifting type drilling platform comprises a main ship body, and a cantilever beam which is arranged on the main ship body, whereinan eccentric type derrick is fixedly connected on the cantilever beam; a drilling tool is arranged in the vertical direction in the eccentric type derrick, and is used for downwards extending into aseabed to perform drilling operation; the eccentric type derrick comprises an un-eccentric type base frame and an eccentric type eccentric frame, wherein the gravity center of the eccentric frame deviates from the geometric center of the base frame in a direction away from the main ship body; and the drilling tool deviates from the position of the geometric center of the base frame in the direction away from the main ship body, so that a drilling operation range is increased, and therefore, the drilling operation process is simplified, drilling time history and an operation period are shortened, and comprehensive operation cost is reduced.

Owner:YANTAI RAFFLES SHIPYARD +2

Tunneling drilling machine

PendingCN110529109AExtended drilling rangeImprove drilling efficiencyDerricks/mastsSlitting machinesEngineeringMechanical engineering

The invention provides a tunneling drilling machine. A tunneling part, a sliding rail assembly and a drilling machine part are included. The sliding rail assembly is arranged on the tunneling part andcomprises a first track, and the included angle is formed between the first track and the tunneling part. The drilling machine part comprises two boring machines which are in sliding connection withthe first track, the boring machines slide along the first track, and accordingly the drilling machine part moves relative to the tunneling part. According to the tunneling drilling machine provided in the scheme, the drilling machine part slides along the first track so that the drilling machine part can move relative to the tunneling part, the first track is used for releasing the freedom degreefor the movement of the drilling machine part relative to the tunneling part, for example, the first track stretches across the left side and the right side of the tunneling part, the drilling machine part can move between the left side and the right side of the tunneling part, the boring machines are more flexible, the boring range of the boring machines is further enlarged, in the scheme, the two boring machines can conduct boring work, and the boring efficiency is improved.

Owner:SANY HEAVY EQUIP

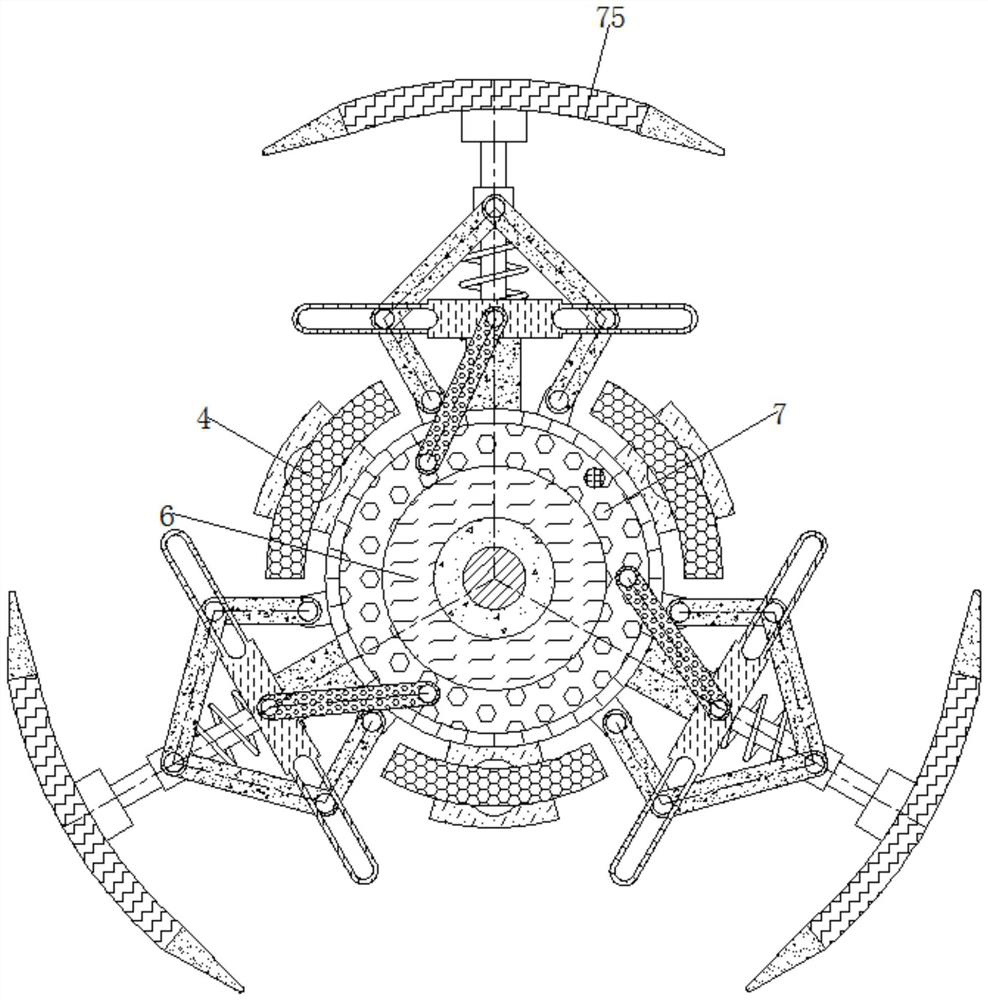

Drill rod for cement mixing pile

PendingCN113530454AExtended drilling rangeImprove versatilityDrill bitsBorehole drivesClassical mechanicsStructural engineering

The invention relates to the field of cement mixing pile drill rods, in particular to a drill rod for a cement mixing pile. The drill rod comprises a drill rod body and a plurality of equal-diameter mixing blades connected to the drill rod body, a diameter changing mechanism is formed at the bottom of the drill rod body, the diameter changing mechanism comprises a lower sleeve body which is arranged on the drill rod body in a sleeving mode and an upper sleeve body which is arranged on the drill rod body in a sliding and sleeving mode, a plurality of diameter changing plates are connected to a portion between the lower sleeve body and the upper sleeve body, the diameter changing plates are arranged in the circumferential direction of the drill rod body, each diameter changing plate comprises an upper connecting plate which is connected to the upper sleeve body in a pivoted mode and a lower connecting plate which is connected to the lower sleeve body in a pivoted mode. the lower connecting plates are connected to the upper connecting plates in a pivoted mode, and the drill rod body is connected with a first driving assembly used for driving the lower sleeve body to vertically slide. The drill rod has the effect of improving the universality of the drill rod.

Owner:无锡市政建设集团有限公司

Aperture-adjustable server cabinet surface punching and auxiliary stripping device

InactiveCN113976942AIncreased drilling rangeImprove drilling efficiencyPositioning apparatusMaintainance and safety accessoriesMachineSlide plate

The invention relates to the technical field of new-generation information, and discloses an aperture-adjustable server cabinet surface punching and auxiliary stripping device which comprises an adjusting assembly, a pull rod is arranged in the adjusting assembly, a sliding plate is movably connected to the surface of the pull rod, and a connecting rod mechanism is slidably connected to the surface of the sliding plate. A telescopic rod is arranged on the surface of the connecting rod mechanism, a cutter head is arranged on the surface of the telescopic rod, a positioning pin is arranged in the adjusting assembly, and the aperture-adjustable server cabinet surface punching and auxiliary stripping device also comprises a machine body. Through cooperative use of a sliding plate and a connecting rod mechanism, cooperative use of a telescopic rod and a cutter head and cooperative use of a positioning pin and a base, the aperture specification of punching can be adjusted, aperture adjustment operating is convenient, the surface punching machining range of the server cabinet can be effectively increased, and the surface punching machining efficiency of the server cabinet can be improved.

Owner:杭州樊兔机电科技有限公司

A Vibrating Rotary Jet Drill Bit

ActiveCN106545298BExtended drilling rangeExpand the attack surfaceDrill bitsLiquid/gas jet drillingImpellerWater flow

The invention discloses a vibration-type rotary-jetting drill bit, pertaining to the field of jetting drill bits. The vibration-type rotary-jetting drill bit at least comprises an expansion section, a drill bit body, an impeller, an eccentric motor, a baffle plate, and bearings. The right end of the drill bit is connected with the expansion section. The drill bit is internally provided with the impeller, the eccentric motor, and the baffle plate in order from the right to the left. The left end of the impeller is connected with a right end of the eccentric motor through one bearing. The left end of the eccentric motor is connected with a right end of the baffle plate through the other bearing. The baffle plate is in threaded connection with the drill bit body. The drill bit body and the surface of the expansion section are inlaid with diamonds. The additional arrangement of the eccentric motor enables the drill bit to vibrate by circumference and helps increase the range of the drill bit. Due to the additional arrangement of the impeller, more high-voltage water flows rotate, the hitting surface of jetting flow is broadened and drilling efficiency is increased. Bu additionally arranging the expansion section, service lifetime of the drill bit is prolonged and the rock breaking surface by jet flows is increased. By inlaying the diamonds on the surface of the drill bit, the effects of mechanically breaking rocks and shaping hole walls are achieved.

Owner:PETROCHINA CO LTD

Arc surface drilling equipment

ActiveCN102198531BImprove drilling accuracyExtended drilling rangePortable drilling machinesBoring/drilling machinesElectricityEngineering

The invention discloses arc surface drilling equipment, which comprises two flexible tracks. A movable framework is arranged on the flexible tracks; a vertical plate is mounted on the movable framework via a linear guide rail; the vertical plate is rotatably connected with a swing plate; and an electric main shaft is mounted on the swing plate. The electric main shaft is slidably connected with the swing plate via a hoop, and the swing plate is connected with a swing driving mechanism. The electric main shaft can move longitudinally, transversely and vertically on the drilling equipment, and can swing and rotate, so a drilling range of the electric main shaft is expanded, absorption positions of the flexible tracks on the surface of a workpiece are not needed to be frequently changed, theworking intensity is reduced, the working efficiency is improved, and the processing cost is lowered; meanwhile, the drilling equipment is more stable, and the drilling precision is improved.

Owner:大连四达高技术发展有限公司

Composite deep hole processing device

ActiveCN104353861BRealize the top tight rotation functionReduce turning momentMaintainance and safety accessoriesBoring/drilling machinesHydraulic cylinderPiston

The invention relates to a complex deep hole machining device. The complex deep hole machining device comprises a BTA (benzotriazole) deep hole drilling tool and a gun-drilling deep hole drilling tool, and further comprises a supporting plate and a spiral chip discharger, wherein the BTA deep hole drilling tool comprises an oil feeder box, a connecting rod, a first guide sleeve, a BTA drill bit, an oil feeder piston and an oil feeder cylinder; the gun-drilling deep hole drilling tool comprises a guide frame box, a guide frame cylinder, a gun-drilling piston, a second guide sleeve, a gun-drilling drill bit, a chip feeding opening and a chip discharging opening. The BTA deep hole drilling tool and the gun-drilling deep hole drilling tool are mounted on the same supporting plate, so that a BTA drilling way and a gun-drilling way coexist and the drilling range is enlarged; the BTA deep hole drilling tool and the gun-drilling deep hole drilling tool are added with rotating components respectively, so that a workpiece tightening and rotating function is achieved and a turning torque of a conventional hydraulic cylinder at the bottom of the supporting plate is reduced.

Owner:SUZHOU XINNENG PRECISE MACHINERY

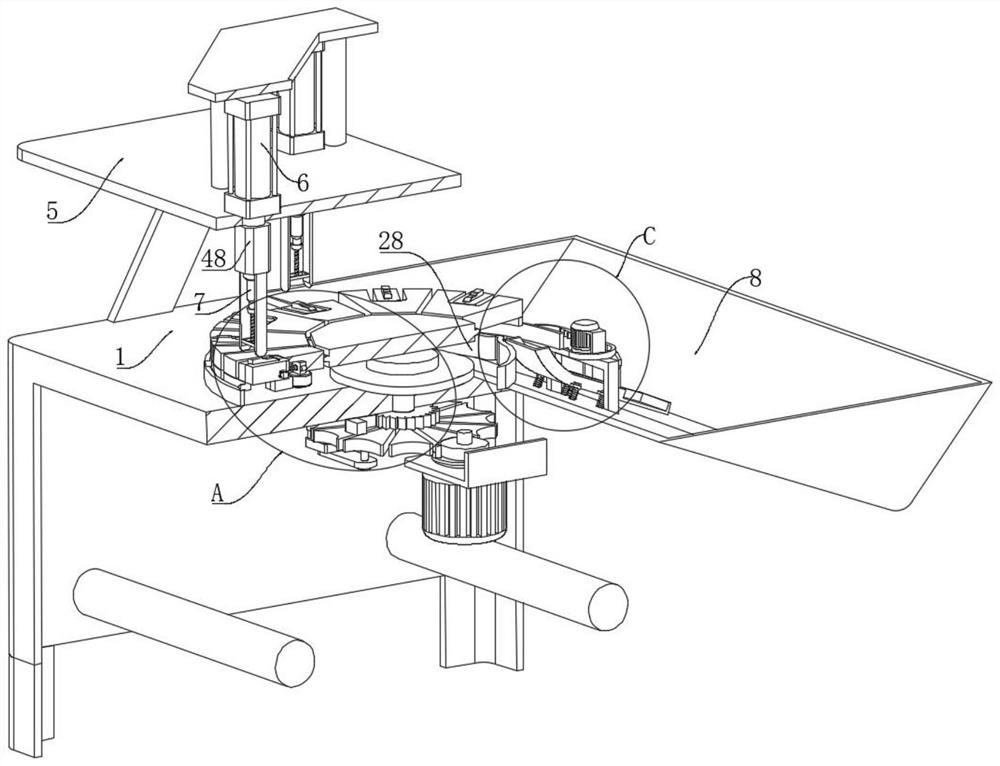

Drilling mechanism used for piano manufacturing

ActiveCN113386210AImprove integrityImprove pronunciationStationary drilling machinesNon-rotating vibration suppressionPianoEngineering

The invention relates to the technical field of piano processing drilling, in particular to a drilling mechanism used for piano manufacturing. The drilling mechanism used for piano manufacturing comprises a supporting seat, wherein a rotating shaft is rotatably connected with the center of the top of the supporting seat, the bottom end of the rotating shaft penetrates through the top of the supporting seat, extends to be below the supporting seat, and is connected with a grooved wheel positioning mechanism, the top of the rotating shaft is fixedly connected with a rotating disc, multiple fan-shaped blocks are rotatably connected with the side face of the rotating disc, rectangular grooves are formed in the sides, away from the rotating disc, of all the fan-shaped blocks, square rods are fixedly connected with the interiors of all the rectangular grooves, and two corresponding placing blocks are inserted into each square rod. According to the technical scheme, hammer head wooden core main bodies are placed in grooves between the placing blocks, so that the probability of deformation damage, to the hammer head wooden core main bodies, caused by force application clamping is reduced, thus the completeness of the hammer head wooden core main bodies is improved, and improvement of the effect that hammer heads knock strings to make sounds is facilitated.

Owner:XINYANG VOCATIONAL & TECHN COLLEGE

A drilling device for decorative wood panels

ActiveCN105459217BComprehensive Drilling ProcessIncrease flexibilityStationary drilling machinesEconomic benefitsEngineering

The invention discloses a drilling device used for a decoration board. The drilling device comprises a rack and a drilling mechanism. Moving mechanisms are arranged on the rack. U-shaped clamping blocks are fixed to one sides of the moving mechanisms. A work platform is arranged between the U-shaped clamping blocks. A multi-groove base is arranged on the work platform in the longitudinal direction. The multi-groove base is connected with a sliding seat in a sliding manner. A rotating mechanism is fixed to the sliding seat. An L-shaped connecting block is arranged on the rotating mechanism. A drilling mechanism is arranged on the L-shaped connecting block. A fixed base is arranged on the rack and is connected with a clamping mechanism. A baffle is arranged on the rack. According to the drilling device used for the decoration board, the combination of the moving mechanisms and the rotating mechanism is used, the drilling device stretches and contracts freely and can rotate left and right by 180 degrees, the drilling range is greatly enlarged, and the drilling technology can be conducted on the decoration board comprehensively. The structure is simple, practicability is high, manufacturing cost is low, and economic benefits are obvious.

Owner:GUANGZHOU SNIMAY HOME FURNITURE CO LTD +1

Drilling mechanism and drilling machine

ActiveCN103485714BShorten the lengthRealize the function of drilling anchor holesDrilling machines and methodsEngineeringRock bolt

Owner:SANY HEAVY EQUIP CO LTD

A drilling mechanism for piano making

ActiveCN113386210BImprove integrityImprove pronunciationStationary drilling machinesNon-rotating vibration suppressionPianoMechanical engineering

The invention relates to the technical field of piano processing and drilling, in particular to a drilling mechanism for piano production, which includes a support seat, a rotating shaft is rotatably connected to the center of the top of the support seat, and the bottom end of the rotating shaft passes through the top of the support seat and extends to A sheave positioning mechanism is connected under the support seat, a rotating disk is fixedly connected to the top of the rotating shaft, and a plurality of fan-shaped blocks are connected to the side of the rotating disk, and the side of the fan-shaped blocks away from the rotating disk is provided with a rectangular groove, and the rectangular grooves are fixed A square rod is connected, and two placement blocks are inserted on each of the square rods; this technical solution places the main body of the hammer wood core in the groove between the placement blocks, reducing the force clamping on the main body of the hammer wood core. The probability of deformation damage is improved, thereby improving the integrity of the main body of the hammer core, which is conducive to improving the sound effect of the hammer hitting the strings.

Owner:XINYANG VOCATIONAL & TECHN COLLEGE

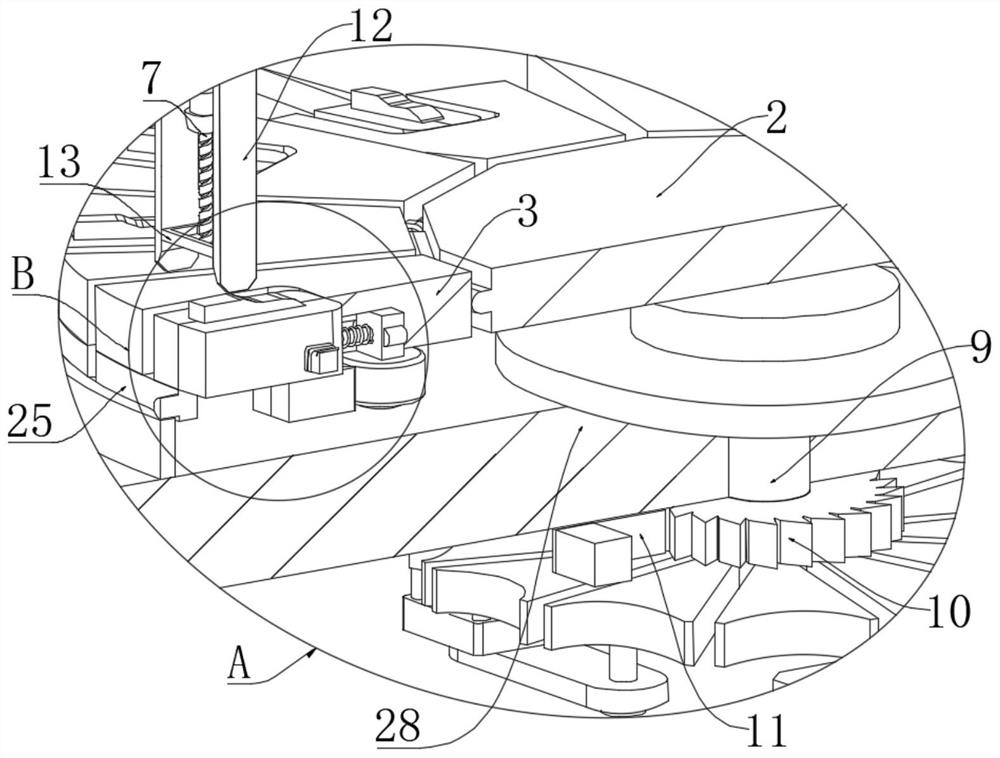

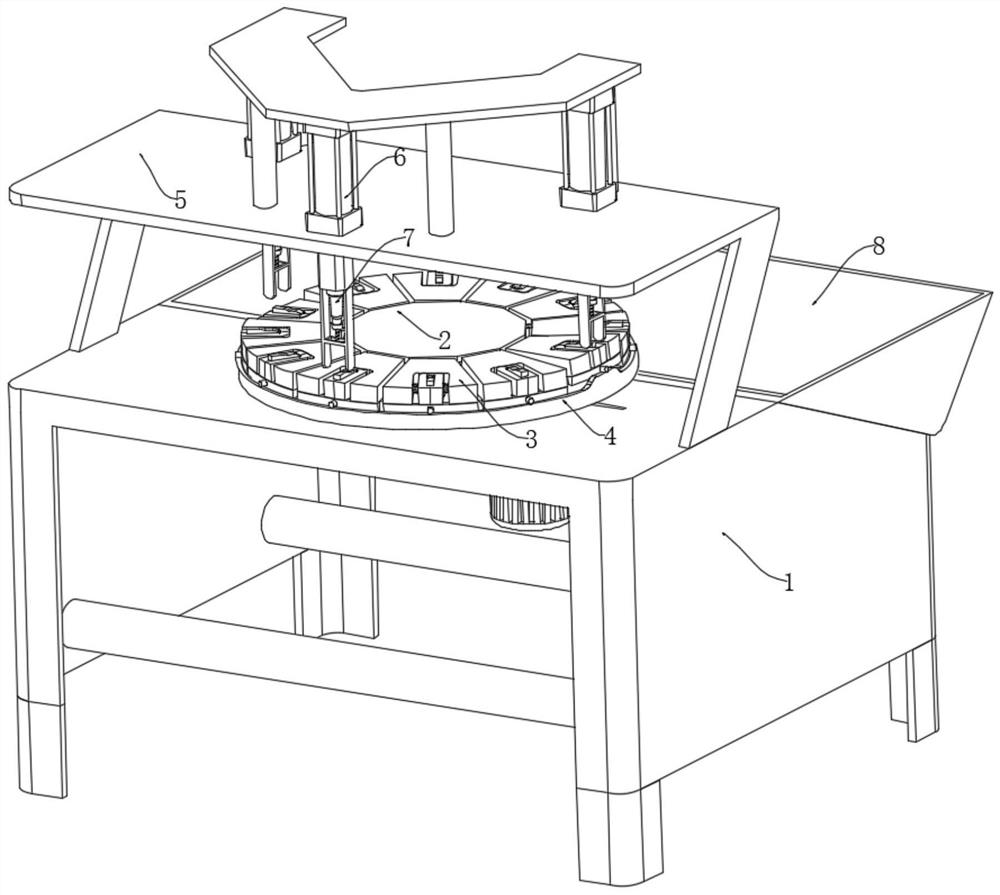

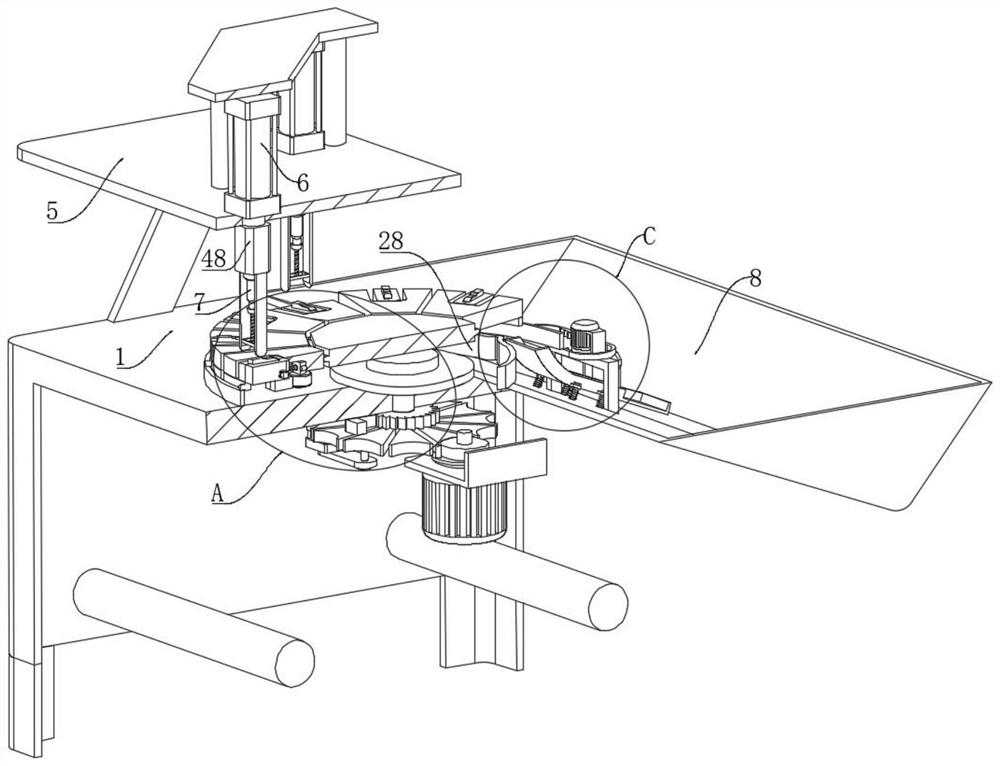

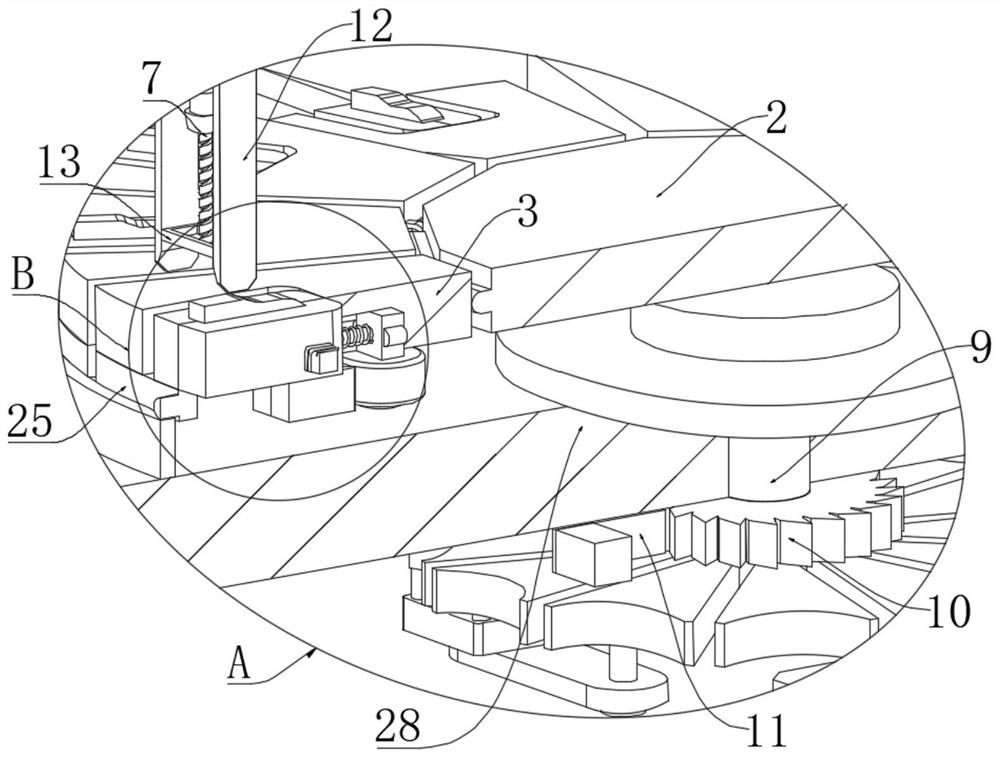

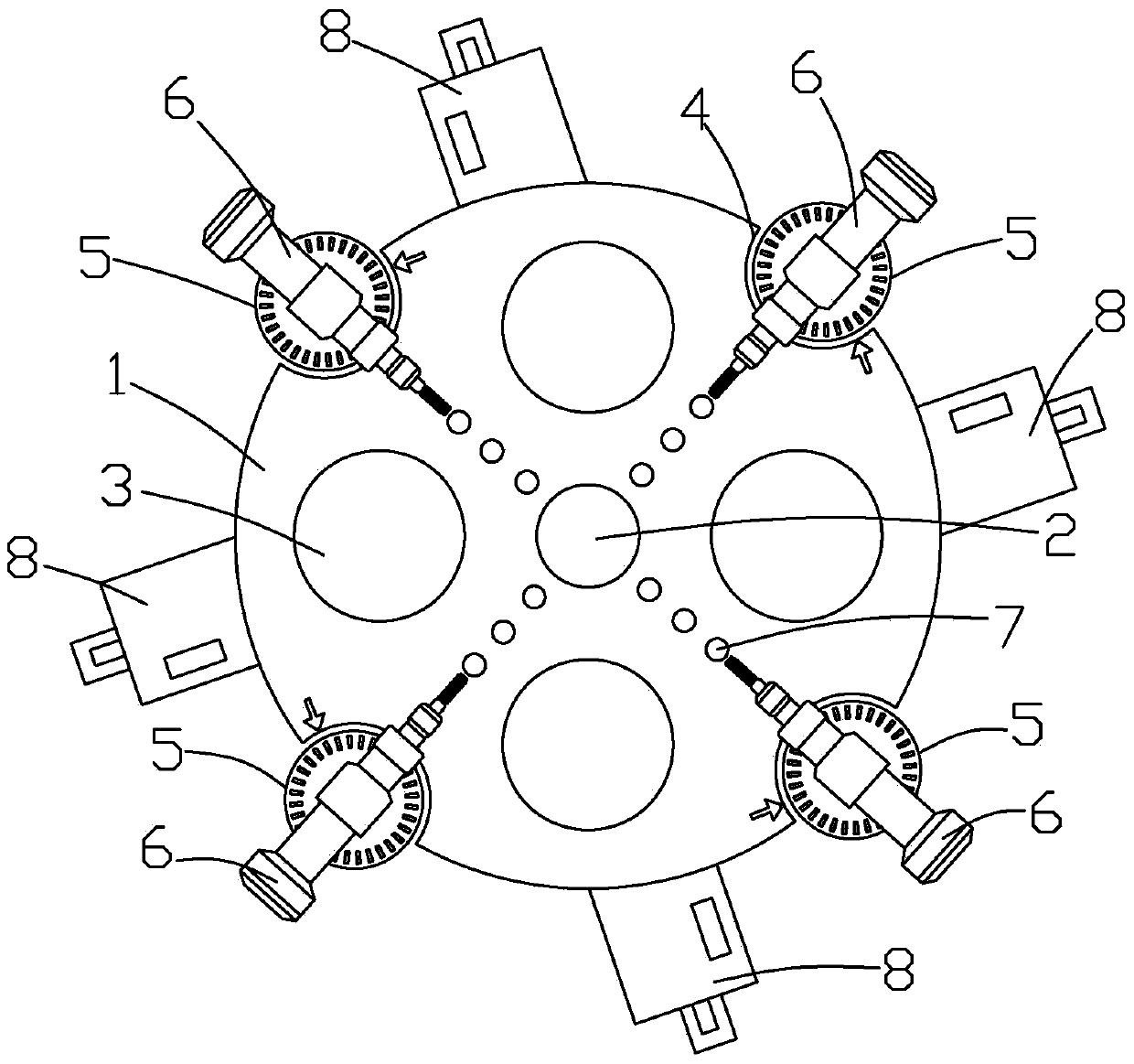

An aluminum bar drilling device used in a hollow glass molecular sieve filling machine

ActiveCN105414603BIncrease flexibilitySmall inertiaMaintainance and safety accessoriesAttachable boring/drilling devicesMolecular sieveHydraulic cylinder

The invention discloses an aluminum strip drilling device for a hollow glass molecular sieve filling machine. The aluminum strip drilling device comprises a main rotary disc, a pneumatic drilling device and drill bit converting frames. At least four semicircular grooves are evenly formed in the outer circumference of the main rotary disc and internally provided with positioning rotary discs. The pneumatic drilling device is connected with the positioning rotary discs through clamping mechanisms. A boosting hydraulic cylinder is arranged at the bottom of the main rotary disc and connected with a horizontal supporting plate through a piston rod. A motor is arranged on the top face of the horizontal supporting plate. Inner cavities are formed in the positioning rotary discs. Annular racks are arranged on the side walls of the inner cavities. The drill bit converting frames are evenly distributed on the outer circumference of the main rotary disc. The aluminum strip drilling device is simple in structure and high in practicability, and aluminum strips of different sizes and specifications can be drilled. Flexible replacement of drill bits can be automatically achieved, the remote positions and the positions hard to machine can be drilled, and the work range of the pneumatic drilling device is widened; and meanwhile the stability of the pneumatic drilling device during rotating is improved.

Owner:江苏铝翔航空科技有限公司

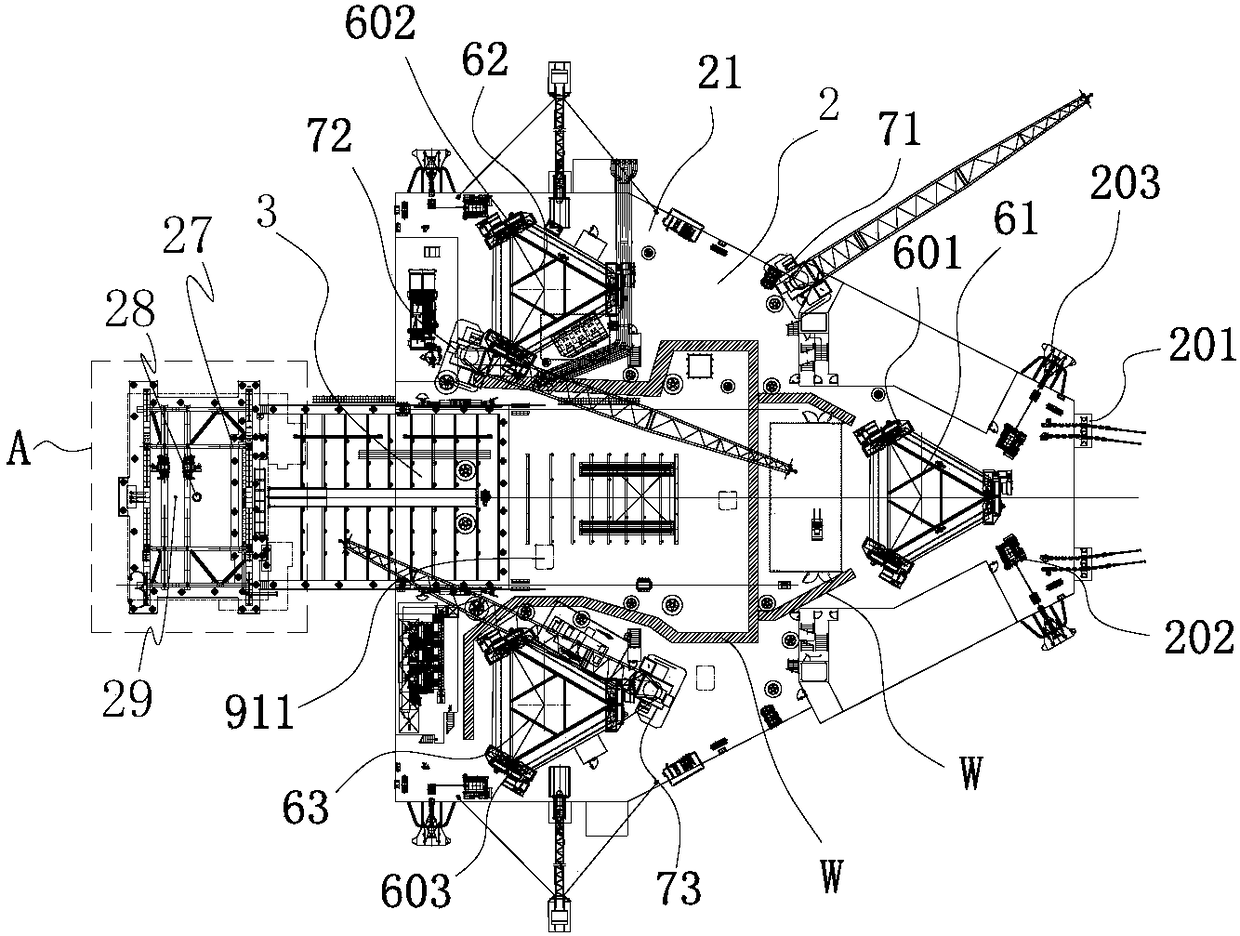

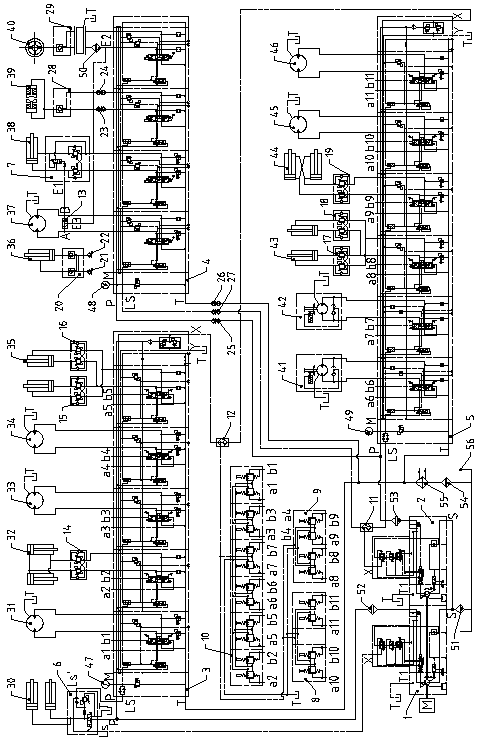

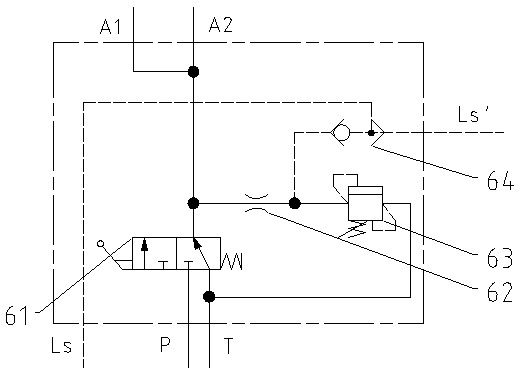

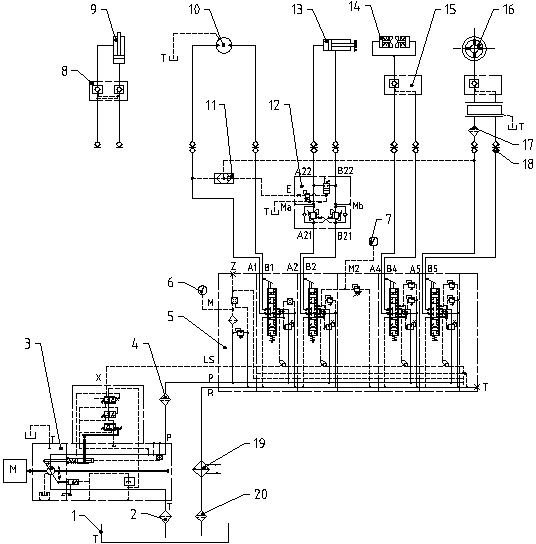

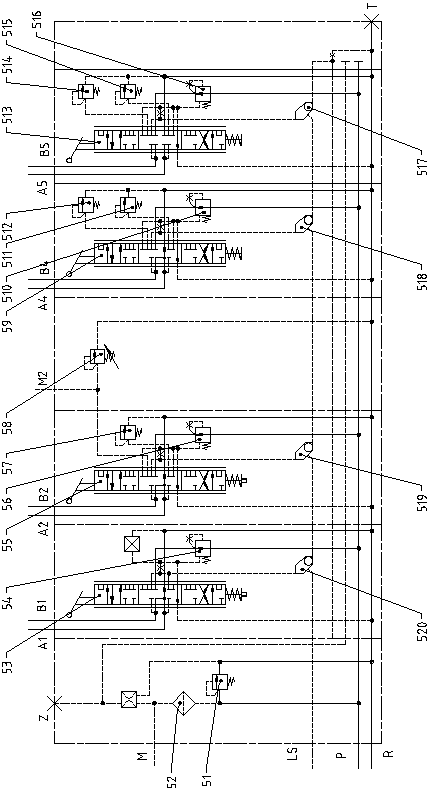

Hydraulic control system of dust removal and outburst prevention integrated heading machine

ActiveCN102996138BExtended drilling rangeImprove safety and reliabilityServomotorsTunnelsLoad sensingControl system

The invention discloses a hydraulic control system of a dust removal and outburst prevention integrated heading machine and belongs to the technical field of excavation equipment. The hydraulic control system comprises a heading machine host control system, a dust removal fan motor control system, an outburst prevention drilling machine control system, a pump station system and a control oil system; a heading machine host, a dust removal fan motor and an outburst prevention drilling machine share the same pump station system, so that the integration level of the hydraulic system is improved, and meanwhile, the utilization ratio of a pump station is increased; by using the outburst prevention drilling machine control system, the drilling range of the outburst prevention drilling machine is widened, the slip problem caused when the drilling machine drills at a large inclined angle is effectively solved, and the safety and the reliability of outburst prevention drilling are improved; a load-sensing technology is adopted in the hydraulic control system, so that the efficiency of the control system is increased, and a better energy-saving effect is achieved; and a load-sensing proportional directional valve is adopted in the hydraulic control system, so that the control precision of an executive component is improved, and the hydraulic control system is simple and convenient to operate.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Stainless steel template lock hole machining center

PendingCN110497224AImprove efficiencyOperational securityFeeding apparatusPositioning apparatusArchitectural engineeringOperation safety

The invention relates to the technical field of building template machining and discloses a stainless steel template lock hole machining center comprising a machining base. Foot pads are fixedly installed on the left and right sides of the bottom of the machining base correspondingly. A fixed upright is fixedly installed on the left side of the top of the machining base. A support shaft plate is fixedly installed on the outer side of the fixed upright. The stainless steel template lock hole machining center is provided with a rotary transverse plate connected to the exterior of the fixed upright rotationally, thus the rotary transverse plate can rotate around the fixed upright, then an electric linear guide rail is started, a movable block drives a drilling device on a movable seat to rotate left and right, meanwhile when the rotary transverse plate rotates around the fixed upright, the drilling range of the drilling device is further widened, drilling machining is conducted on different positions of a stainless steel template conveniently quickly, the position of the stainless steel template does not need to be adjusted manually, drilling efficiency of the stainless steel templateis improved, and operation safety is also improved.

Owner:江苏丹佛智能装备科技有限公司

Coal mine tunneling device

InactiveCN112780292AExtended drilling rangeIncrease the areaMine roof supportsTunnelsMining engineeringMechanical engineering

The invention relates to the technical field of coal mine equipment, and discloses a coal mine tunneling device. The coal mine tunneling device comprises a bearing base, a walking belt installed on the bearing base, a drill bit and a power piece for driving the drill bit to rotate, a fixing box is connected to the bearing base, a control rod is hinged to the fixing box, the end, away from the fixing box, of the control rod is connected with a driving box, a driving piece used for driving the drill bit to swing in a reciprocating mode is arranged in the driving box, a control air cylinder is hinged to the fixing box, and an output shaft of the control air cylinder is hinged to the driving box. The crushing effect of the drill bit can be improved, and the crushing efficiency is improved.

Owner:CHONGQING VOCATIONAL INST OF ENG

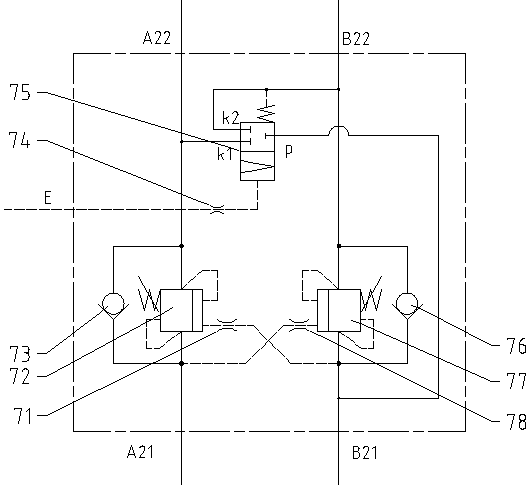

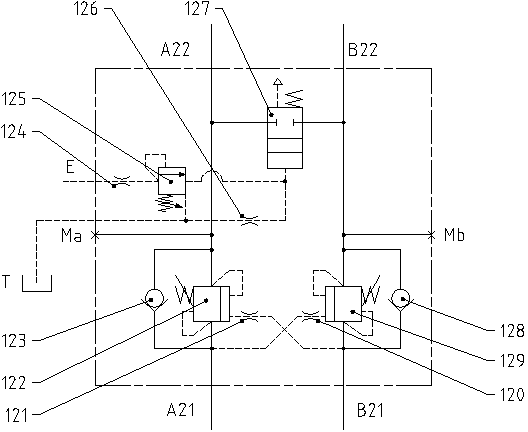

Hydraulic control system for mining full-hydraulic underground drill

InactiveCN102966612BImprove efficiencyGood energy saving effectServomotor componentsServomotorsControl systemShuttle valve

The invention discloses a hydraulic control system for a mining full-hydraulic underground drill and belongs to the technical field of underground drill equipment. The hydraulic control system comprises a plunger pump, a multi-way reversing valve, a first pressure gauge, a second pressure gauge, a two-way hydraulic lock, a slope regulating oil cylinder, a rotary motor, a shuttle valve, a boosting oil way control block, a boosting oil cylinder, a holder, a one-way hydraulic lock, a chuck and a cooler. The hydraulic control system adopts a load sensitivity technique, the efficiency of the control system is improved, the problems that the control is lagged, the control precision is lower, and the system heating is severe are solved, and the energy-saving effect is good; the hydraulic control system adopts the load-sensitive manual proportional reversing valve, the control precision of the control system is improved, and the operation is simple and convenient; with the adoption of the boosting oil way control block, the drilling scope of a drill is extended, the problem that the drill skids when drilling at a large inclination angle is effectively solved, and the drilling safety is improved; and the holder and the chuck are combined and rotate reversely for automatically dismounting a drilling rod, the labor intensity for dismounting the drilling rod is reduced, and the working efficiency is improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

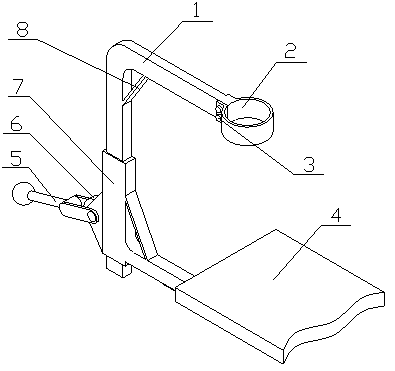

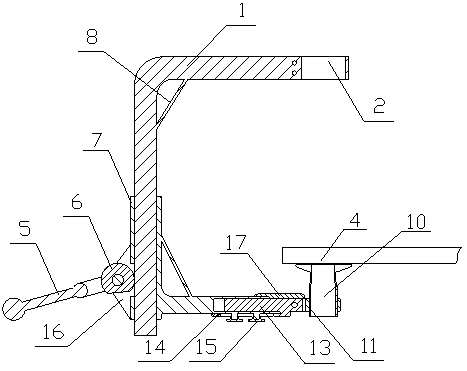

Drilling auxiliary device for electric hand drill

PendingCN111014779AIncrease distanceExtended drilling rangeWork benchesPortable drilling machinesDrill holeGeotechnical engineering

The invention discloses a drilling auxiliary device for an electric hand drill. The distance is adjusted through a telescopic rod, the drilling range is wide, the angle between a drilling machine anda workpiece can be adjusted, and time and labor are saved. The drilling auxiliary device for the electric hand drill is characterized in that an L-shaped clamping plate is formed by fixedly connectinga transverse plate and a vertical plate, a reinforcing plate is arranged between the transverse plate and the vertical plate, a rack is arranged on one side of the vertical plate, a sliding sleeve isan L-shaped sleeve composed of a vertical pipe and a transverse pipe, a reinforcing rod is arranged between the vertical pipe and the transverse pipe, the vertical pipe of the sliding sleeve is arranged on the vertical plate of the L-shaped clamping plate in a sleeving manner, the sliding sleeve can slide along the vertical plate, a fixing base is fixedly arranged on one side of the vertical pipeof the sliding sleeve, one end of a rotating rod is arranged on the fixing base through a connecting shaft, a gear is arranged on the connecting shaft in a sleeving manner, a receding groove is formed in one side of the vertical pipe of the sliding sleeve, the gear is engaged with the rack on one side of the vertical plate through the receding groove, and a notch is formed in the gear to form a plane.

Owner:李广超

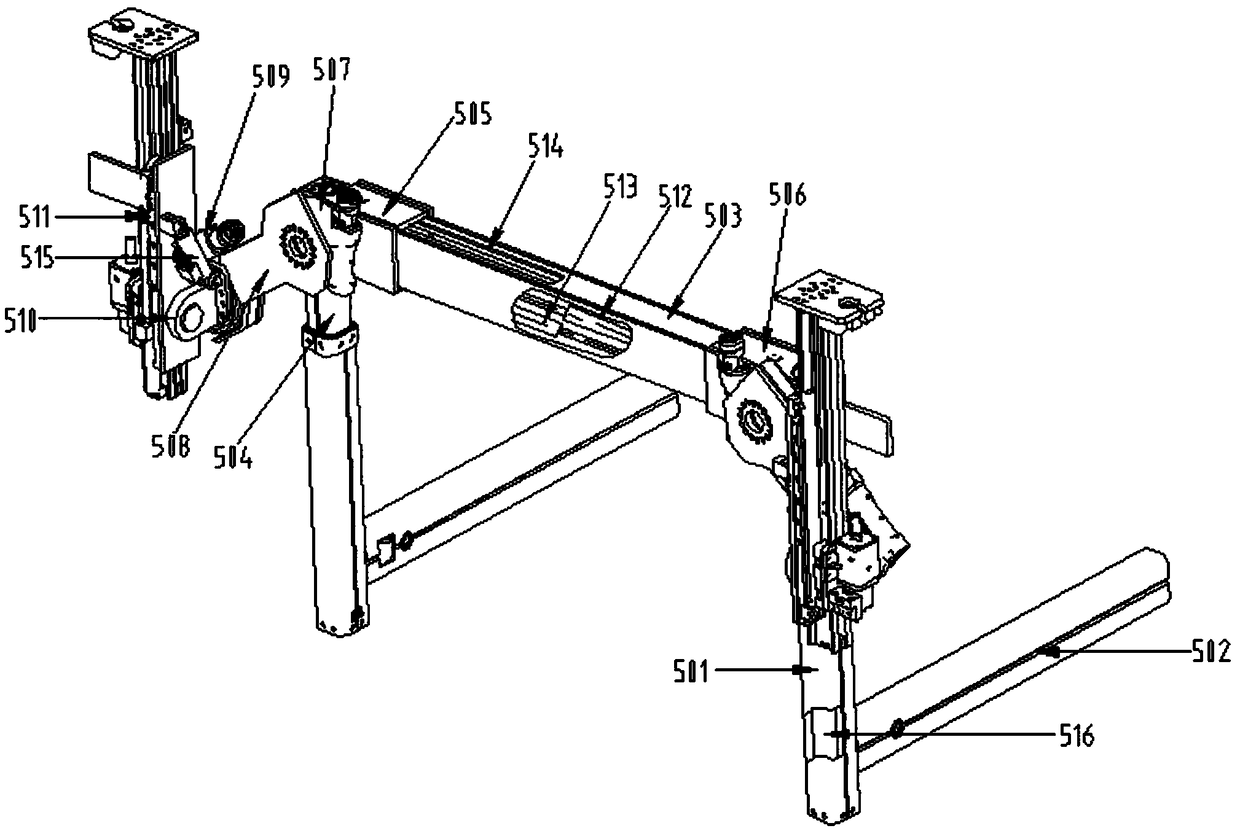

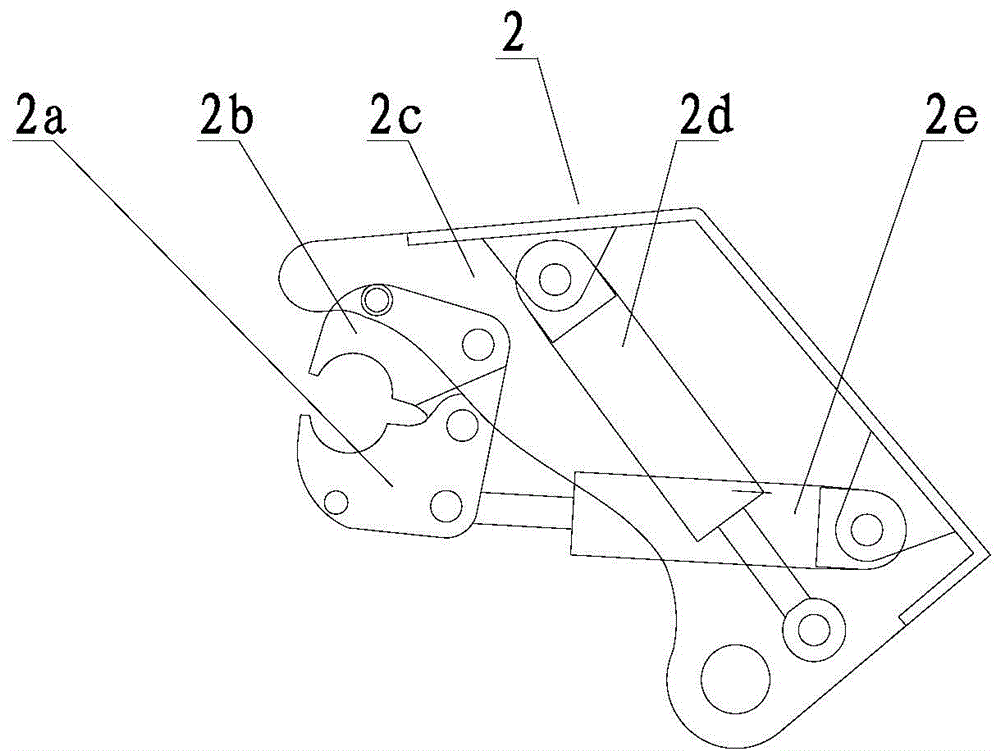

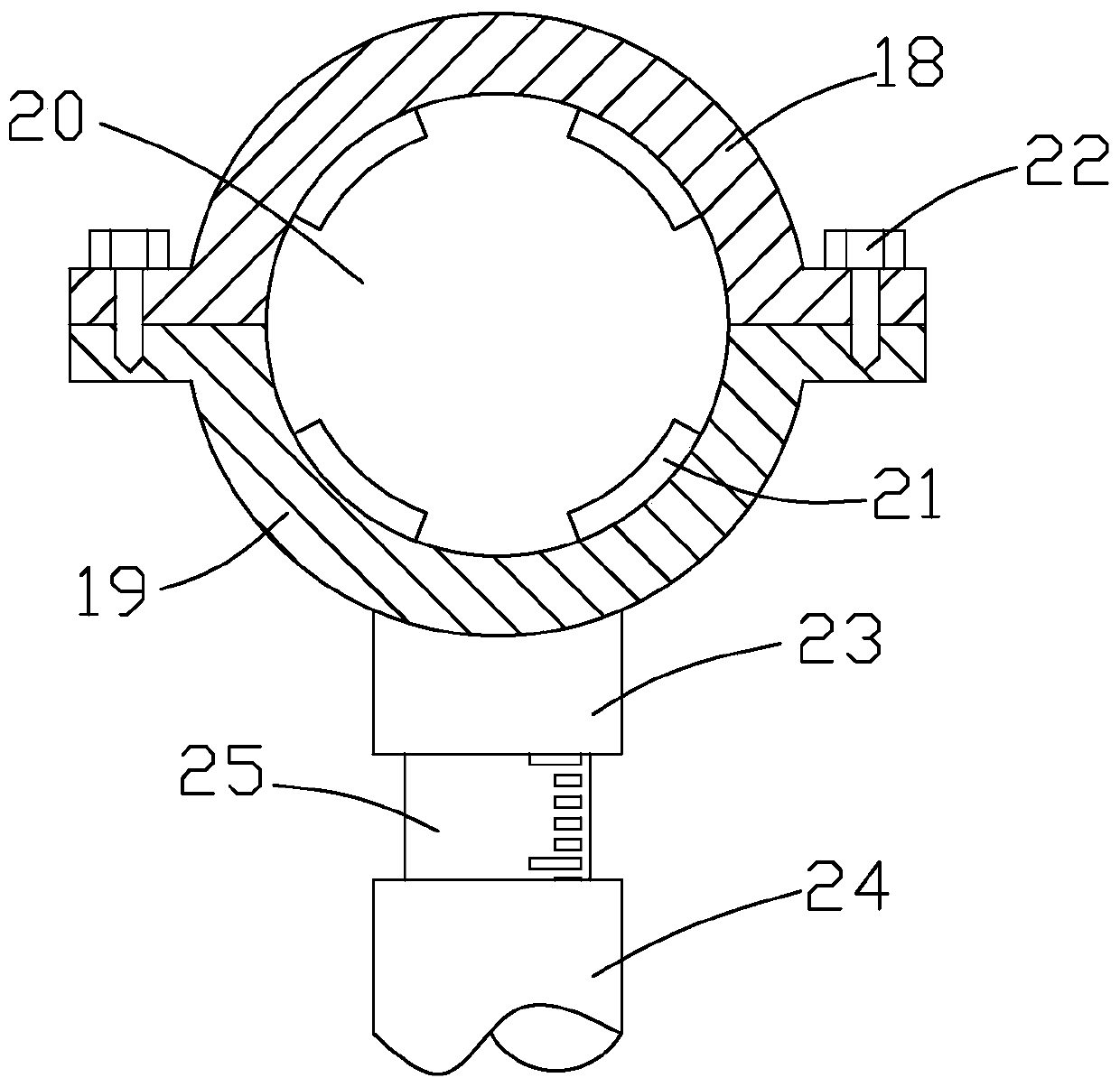

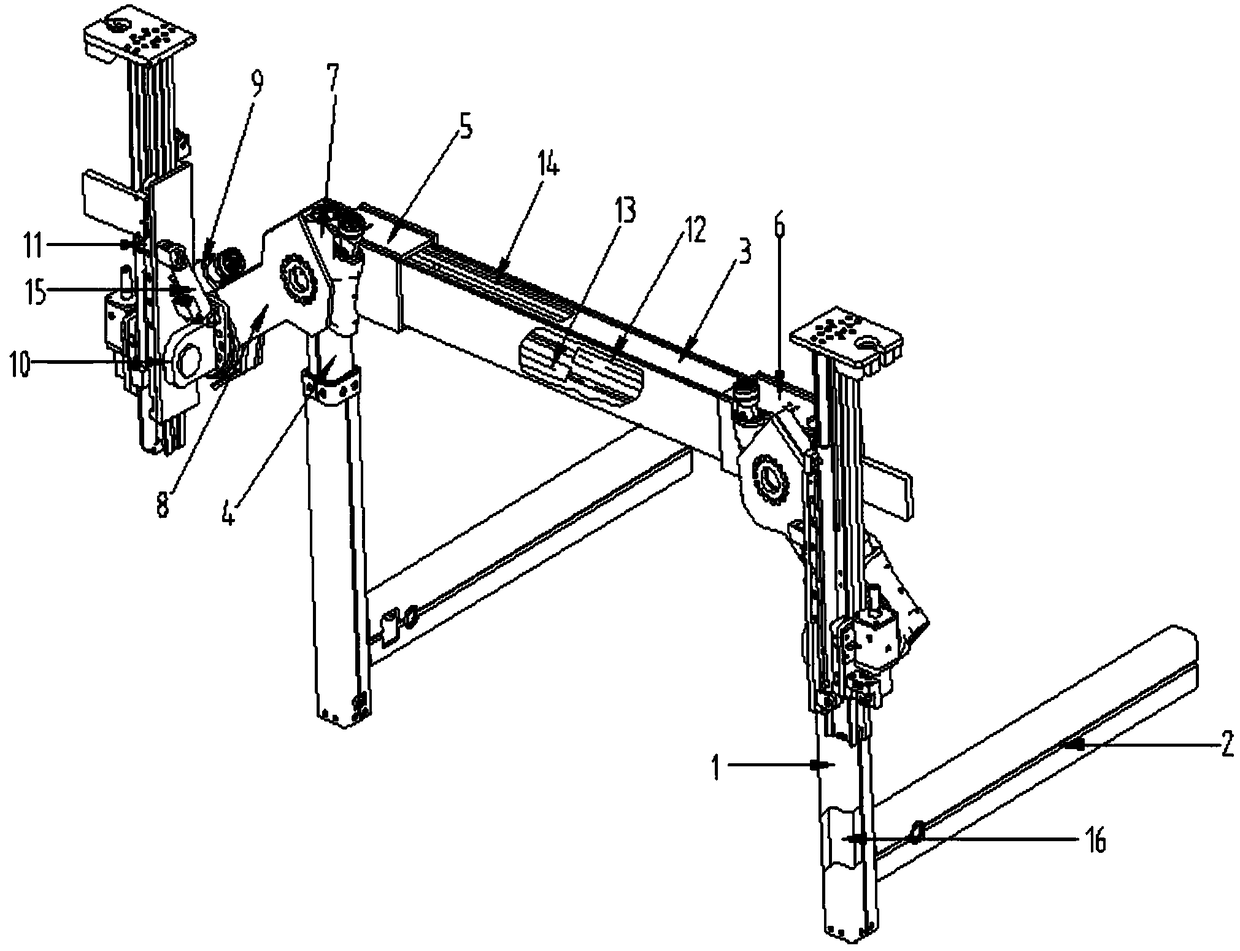

Mechanical anchor drilling assembly

PendingCN109296321AIncreased drilling rangeFast footageDerricks/mastsAnchoring boltsReducerEngineering

The invention provides a mechanical anchor drilling assembly. The mechanical anchor drilling assembly comprises two L-shaped brackets and a cross beam. The L-shaped brackets comprise vertical barrelsand horizontal barrels, and the vertical barrels and the horizontal barrels are perpendicularly connected; and the two ends of the cross beam are connected with vertical inner barrels correspondingly,and the vertical inner barrels are correspondingly inserted into the vertical barrels of the L-shaped brackets and slidably connected with the vertical barrels. The mechanical anchor drilling assembly is characterized in that a first sliding sleeve and a second sliding sleeve which are slidably connected with the cross beam are arranged on the cross beam in a sleeving mode, the first sliding sleeve and the second sliding sleeve are correspondingly and rotatably connected to one end of a rotary frame through a first rotation speed reducer, the other end of the rotary frame is rotatably connected with a supporting seat through a second rotation speed reducer, and the supporting seat is hinged to a roof bolter. According to the mechanical anchor drilling assembly, punching operating ranges can be increased, the penetration speed is improved, and the labor intensity is reduced.

Owner:山东浩吉矿业装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com