Excavating and drilling machine

A technology for excavating drilling rigs and drilling rigs, which is applied to drilling equipment, cutting machinery, earth-moving drilling and mining, etc., can solve the problems of time-consuming and laborious, small drilling scope, etc., and achieve the effect of expanding the scope of activities, increasing the scope of drilling, and expanding the scope of drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

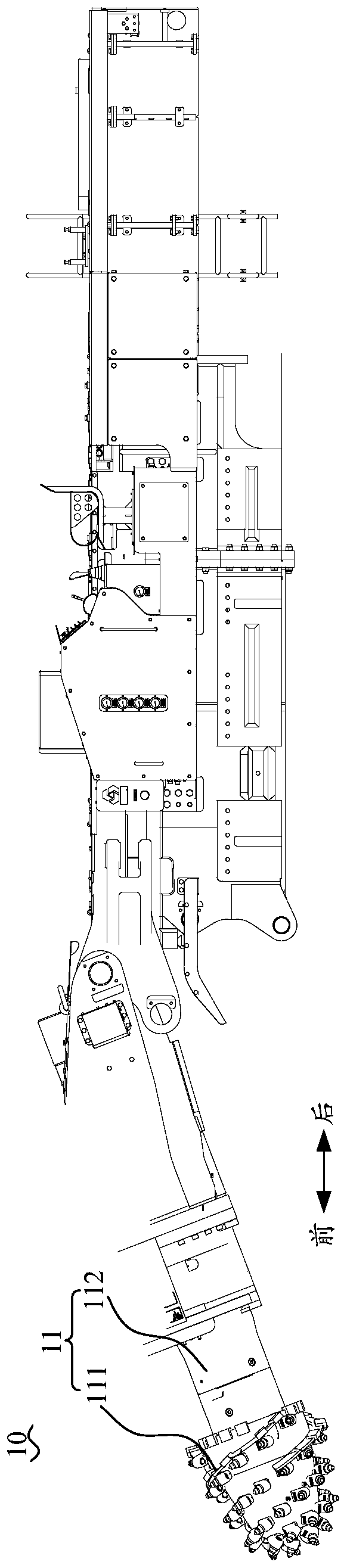

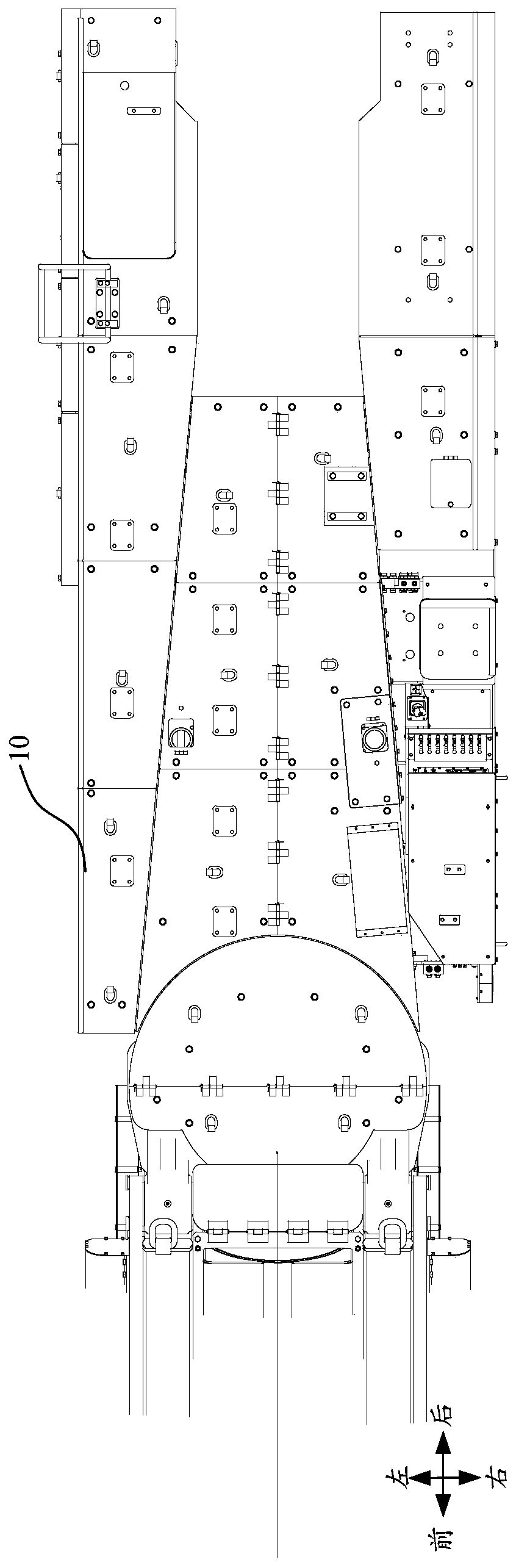

[0049] Such as Figure 5 As shown, in addition to the features described in the above embodiments, it is further defined that: the first rail 121 extends along the length direction perpendicular to the excavation portion 11 . In this way, in the case of the same track length, the distance from the first track 121 to the excavation part 11 is the largest, so that the drilling machine part 13 can obtain a larger drilling range in the left and right directions.

Embodiment 2

[0051] Such as Figure 5 and Figure 6 As shown, in addition to the features described in any of the above embodiments, it is further defined that: the first track 121 includes an arc track or a straight track. In this way, the movable range of the drilling machine part 13 on the vertical height is further increased by the arc-shaped track, and then the drilling height of the drilling machine part 13 is increased, and the arc-shaped track design makes the motion track of the drilling machine part 13 roughly arc-shaped, which is more suitable. It is suitable for the construction environment where arches are required, such as roadways.

[0052] Of course, the first track 121 can also be set to include a straight track, so that the sliding of the drill unit 13 on the straight track is smoother and more stable.

Embodiment 3

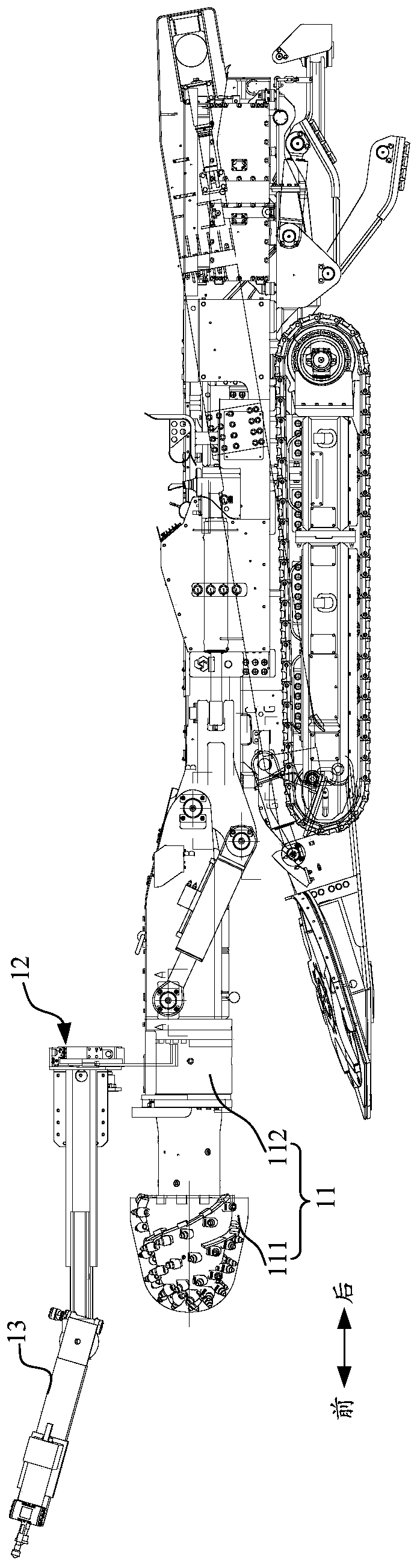

[0054] Such as figure 1 As shown, in addition to the features described in any of the above embodiments, it is further defined that: the first track 121 is connected to the cutting arm 112 and is located on the cutting arm 112 close to the cutting head 111 . Make the drilling machine part 13 closer to the front side of the complete machine, further expand the drilling depth of the drilling machine part 13.

[0055] Further, as figure 1 and Figure 4 As shown, the slide rail assembly 12 includes a mounting bracket 129 , one end of the mounting bracket 129 is connected to the first rail 121 , and the other end is disposed on the cutting arm 112 close to the cutting head 111 .

[0056] For example, the mounting bracket 129 includes support rods arranged at the left and right ends of the first rail 121. Preferably, the mounting bracket 129 and the first rail 121 are fixedly connected by screw fasteners, wherein the support on the left side The rod is connected to the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com