Arc surface drilling equipment

A technology of drilling equipment and arc surface, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc. It can solve the problems of poor stability of the mobile frame, error of drilling position, high processing cost, etc., to achieve The effect of improving drilling accuracy, reducing working intensity and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

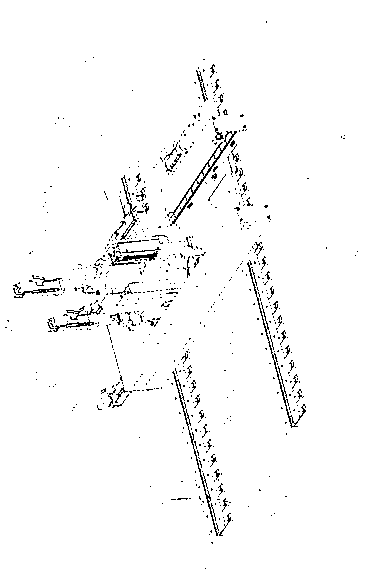

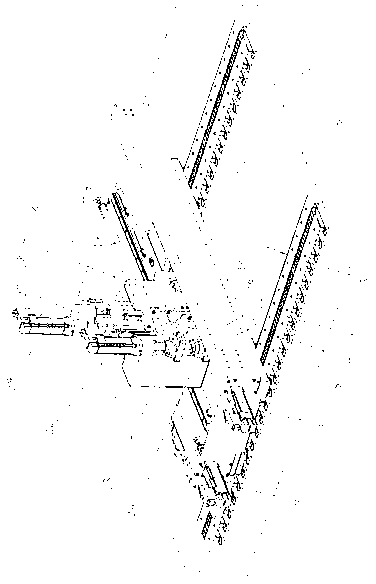

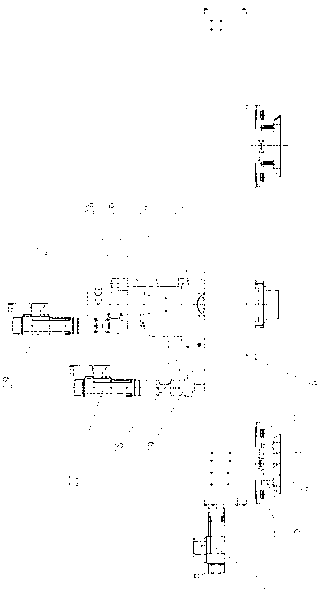

[0017] like figure 1 , 2 , 3 and 4: there are two rows of flexible rails, the flexible rail includes a rail plate 1, and two rows of connecting columns 5 are arranged below the rail plate 1, and the connecting columns 5 and the rail plate 1 are fixedly connected by nuts. A suction cup 4 is connected to the lower end of each pair of connecting columns 5 . Through slots 2 are arranged on the track plate 1 , gear teeth 3 are arranged between adjacent through slots 2 , and the through slots 2 and the gear teeth 3 form a rack structure. The above-mentioned flexible track is in the prior art and will not be described in detail.

[0018] A frame 6 is provided on the two rows of flexible rails, and the frame 6 is made of welded section steel. Running wheels 11 are provided on both sides of the track board 1 in each row of flexible tracks, that is, the running wheels 11 can roll along the sides of the track board 1 . The traveling wheel 11 is installed under the frame 6 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com