Composite deep hole machine tool

A machine tool and deep hole technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of high processing cost, time-consuming and laborious, etc., to increase the range and reduce deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings.

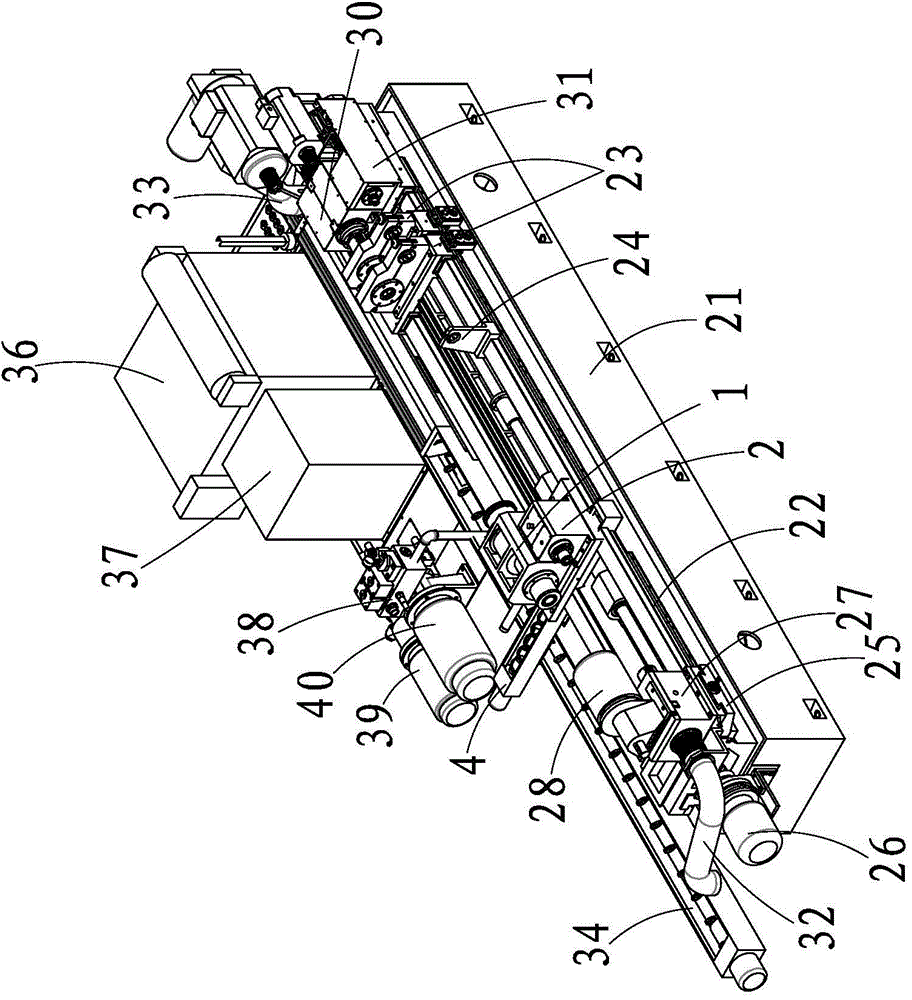

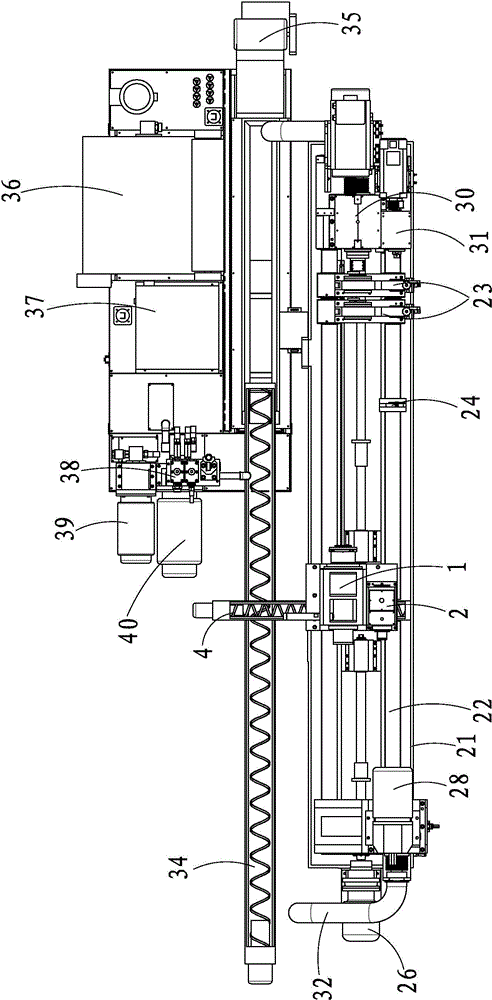

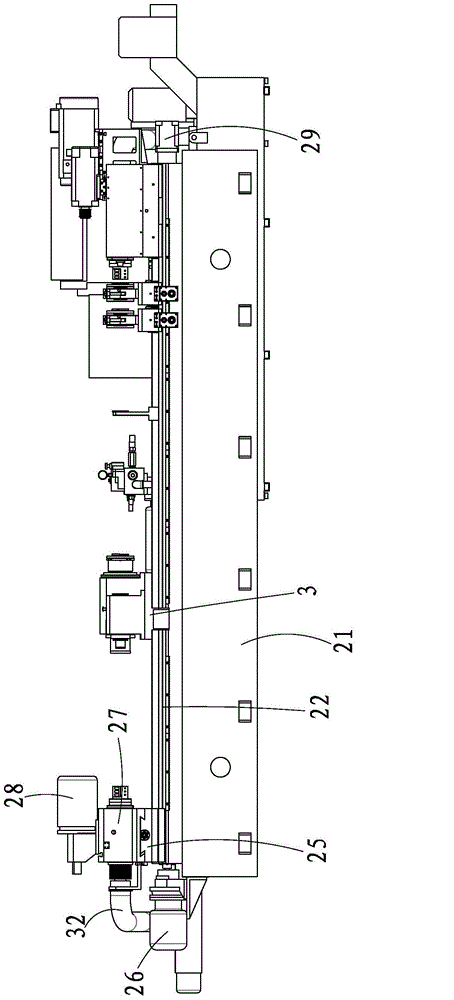

[0027] As shown in the accompanying drawings, a compound deep hole machine tool includes a bed body 21, a drilling tool, a driving mechanism and a guide mechanism arranged on the bed body 21 for driving the drilling tool to drill holes, and is arranged on the bed body 21. The chip recovery mechanism and the cooling filter mechanism of the present invention, the drilling tools include BTA drill rods and gun drills arranged in parallel, and the BTA drill rods and gun drills are commercially available.

[0028] The guiding mechanism includes a clamping device which is slidably arranged on the front part of the bed body 21 in the front and rear direction for clamping the workpiece, an oil receiver 1 and a guide frame 2 arranged side by side on the bed body 21 along the left and right directions, and the BTA drill pipe The front part of the gun drill is penetrated in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com