Industrial robot automatic drilling system and using method

An industrial robot, robot technology, applied in boring/drilling, drilling/drilling equipment, manipulators, etc., can solve the problems of high processing cost of large drilling machines, low hole processing accuracy, long processing cycle, etc. Low, high yield, the effect of increasing the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

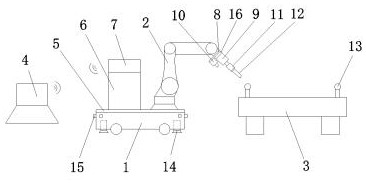

[0029]An industrial robot automated drilling system, seefigure 1 , Including automatic guided car 1, industrial robot 2, processing platform 3 and data processing platform 4. The automatic guided car 1 is equipped with a bottom plate 5 on the top, the top right side of the bottom plate 5 is installed with an industrial robot 2, and the top left side of the bottom plate 5 is installed The robot controller 6 is equipped with a PLC controller 7 on the top of the robot controller 6; a connecting board 8 is installed at the end of the sixth axis of the industrial robot 2, and the connecting board 8 is installed with a motor 9 and a camera 10 respectively. The output terminal of the motor 9 is connected with One end of the chuck 11 is connected, and the other end of the chuck 11 clamps the drill bit 12; the PLC controller 7 is respectively connected with the automatic guided car 1, the robot controller 6, the motor 9 and the camera 10 through cables; the data processing platform 4 is cont...

Embodiment 2

[0032]An industrial robot automated drilling system, seefigure 1 , Similar to Embodiment 1, the difference is that four supporting legs 14 are installed at the bottom of the automatic guided vehicle 1, and the four supporting legs 14 are distributed at the four corners of the automatic guided vehicle 1. When the automatic guided vehicle 1 stops, The four supporting legs 14 push up the automatic guiding cart 1 and the supporting legs 14 make the automatic guiding cart 1 more stable when it stops at the processing position.

[0033]It may be further that the bottom surface of the support leg 14 is provided with horizontal and vertical anti-skid patterns to improve the friction with the ground.

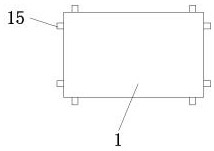

[0034]It can go further, seefigure 2 The four sides of the automatic guided vehicle 1 are respectively installed with distance sensors 15 which detect that a person is approaching, and the industrial robot 2 automatically stops moving to protect the safety of the persons.

[0035]It can be further that...

Embodiment 3

[0052]The use method of an industrial robot automated drilling system as described in embodiments 1 and 2, includes the following steps:

[0053]In the first step, the workpiece with clamping tooling is fixed on the processing platform 3, and the positional relationship between the reference ball 13 and the workpiece is fixed;

[0054]The second step is to correct the positional relationship between the industrial robot 2 and the camera 10 and the drill bit 12;

[0055]In the third step, the reference ball 13 is measured by the camera 10, and the coordinate system of the industrial robot 2, the camera 10, the drill bit 12 and the reference ball 13 are unified on the data processing platform 4 to obtain the positional relationship between the drill bit 12 and the workpiece;

[0056]In the fourth step, the drill bit 12 starts to drill holes on the workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com