Drill rod for cement mixing pile

A technology of cement mixing piles and drill pipes, which is applied in the direction of drill bits, sheet pile walls, drilling equipment, etc., can solve the problems of poor versatility, achieve the effects of improving uniformity, improving versatility, and ensuring construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

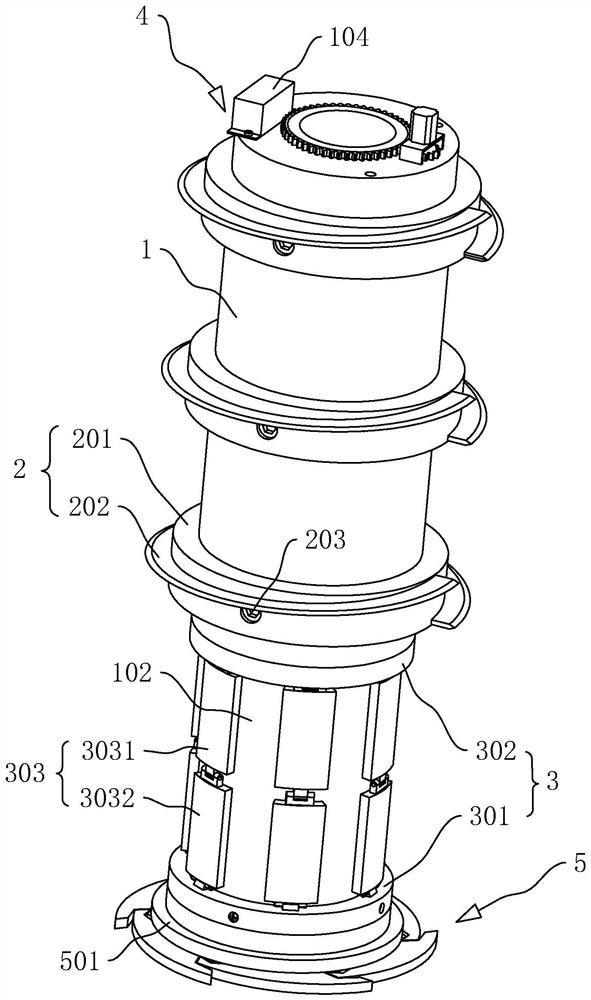

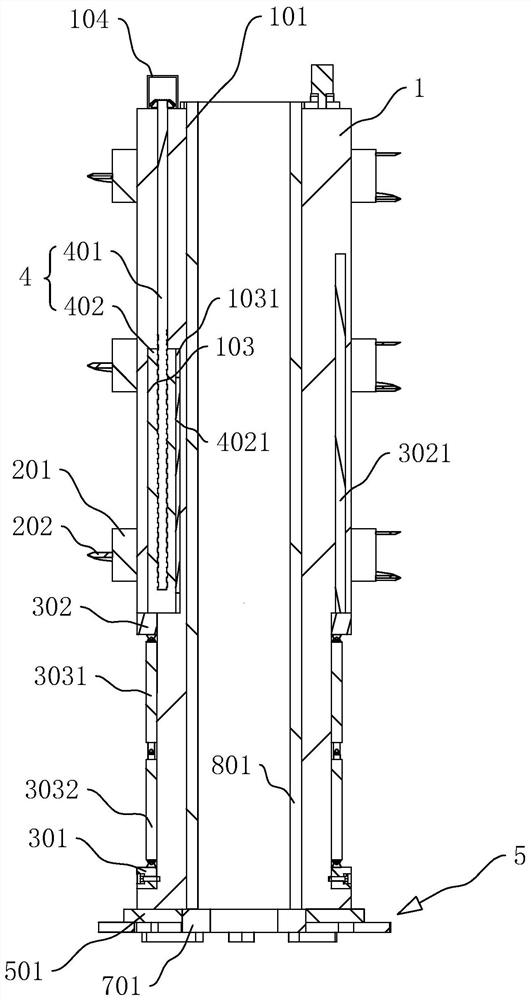

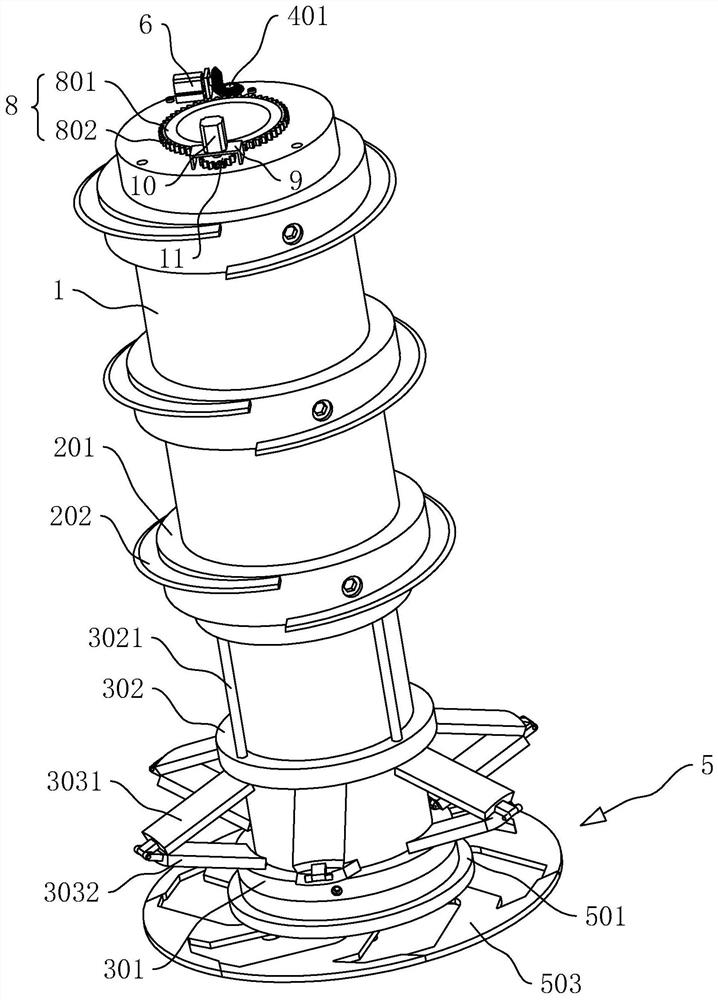

[0035] The following is attached Figure 1-5 The application is described in further detail.

[0036] The embodiment of the application discloses a drill pipe for a cement mixing pile. refer to figure 1 and figure 2 The drill pipe for cement mixing piles includes a vertically arranged drill pipe body 1, and a grouting channel 101 is vertically opened on the drill pipe body 1, and the grouting channel 101 runs through the drill pipe body 1, and the center line of the drill pipe body 1 and The centerlines of the grouting channels 101 are collinear.

[0037] refer to figure 1 The outer wall of the drill pipe body 1 is connected with equal-diameter stirring blades 2 , and several equal-diameter stirring blades 2 are arranged along the axial direction of the drill pipe body 1 . The equal-diameter stirring blade 2 includes a mounting sleeve 201 and a blade body 202 , and the mounting sleeve 201 is sleeved on the drill pipe body 1 .

[0038] refer to figure 1 , the mounting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com