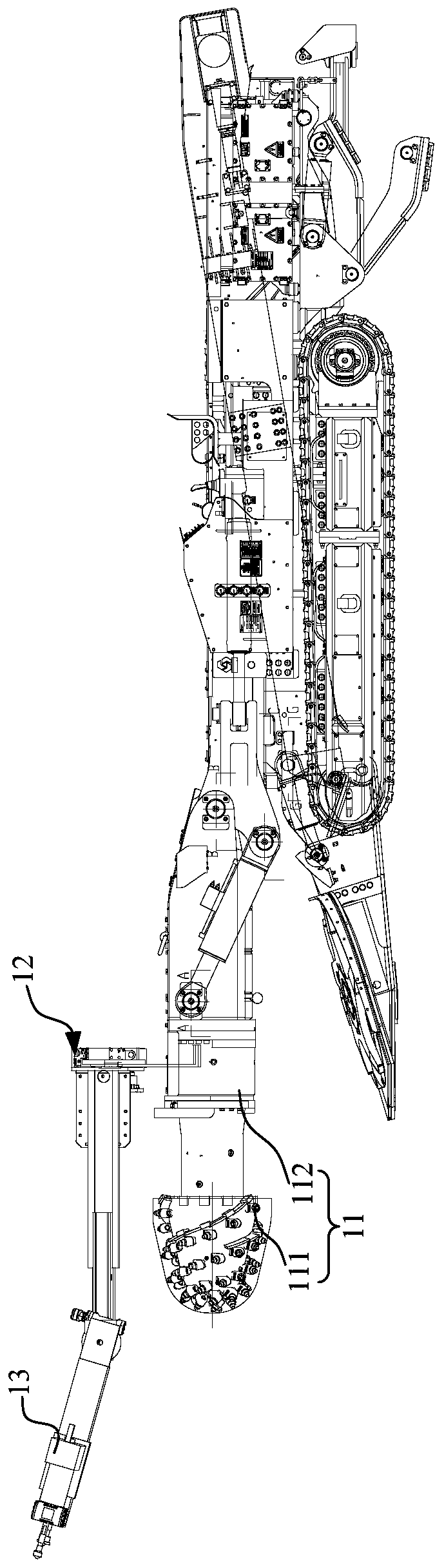

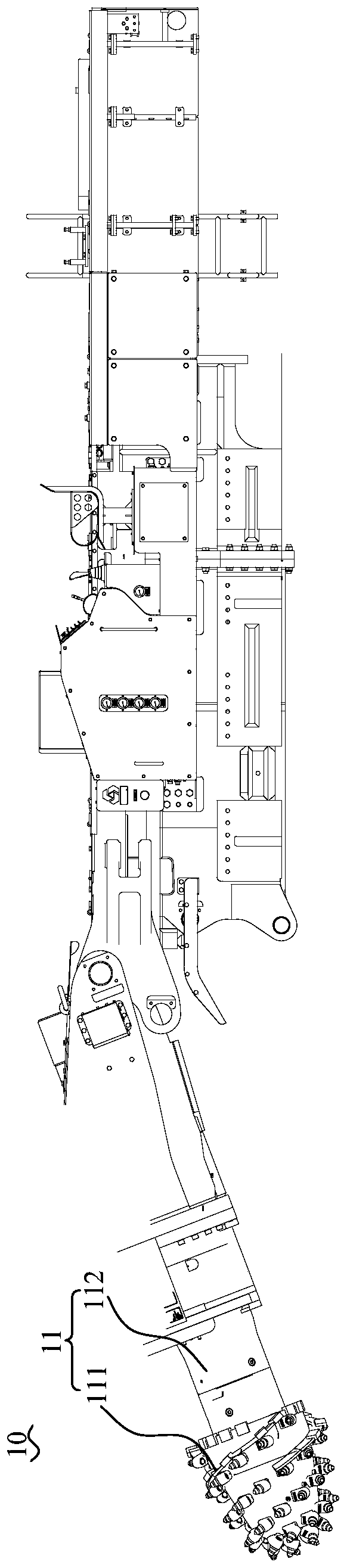

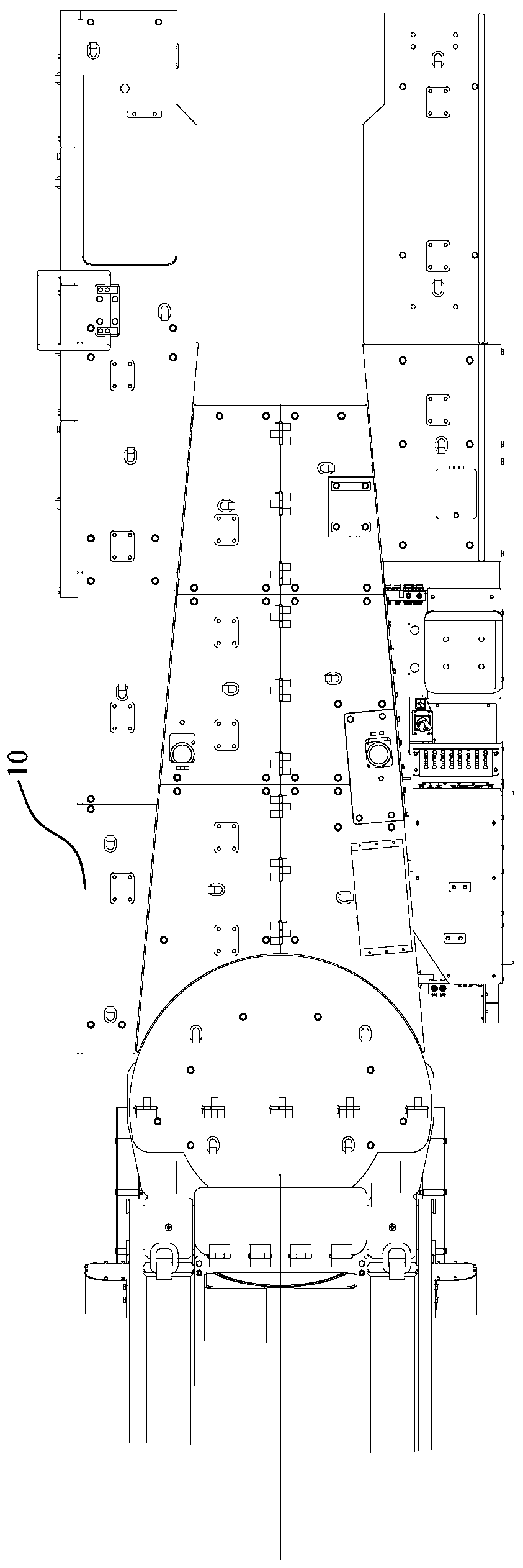

Tunneling drilling machine

A technology for excavating drilling rigs and drilling rigs, which is applied in drilling equipment, cutting machinery, earth-moving drilling and mining, etc., can solve the problems of time-consuming and laborious, small drilling range, etc., and achieve the effect of increasing drilling range and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Such as Figure 5 As shown, in addition to the features described in the above embodiments, it is further defined that: the first track 121 is provided with a stopper 122, and the stopper 122 divides the first track 121 into a first sliding area 1201 and a second sliding area In zone 1202 , two drilling machines 131 are set in one-to-one correspondence with the first sliding zone 1201 and the second sliding zone 1202 . The partition of the first track 121 is realized by the stopper 122, and the two drilling machines 131 move in their respective sliding areas, so as to avoid the mutual interference of the two drilling machines 131 during the movement, collision and other accidents, and further improve the drilling machine 131. operational reliability.

[0049] Further, the stop portion 122 is located in the middle area of the first track 121 . In this way, the stopper 122 roughly divides the first rail 121 into two sliding areas, the range of motion of the two drilli...

Embodiment 2

[0052] Such as Figure 5 and Figure 6 As shown, in addition to the features described in the above embodiments, it is further defined that: the first track 121 is arc-shaped. For example, the first track 121 is in the shape of an arc with the middle protruding upwards and the left and right ends extending downwards. In this way, the arc-shaped track further increases the range of motion of the drilling machine 131 in vertical height, thereby increasing the drilling capacity of the drilling machine 131. In addition, the arc-shaped track design makes the trajectory of the drilling machine 131 roughly arc-shaped, which is more suitable for construction environments such as roadways that require arching.

[0053] Certainly, in other embodiments, a track 121 may also be designed to be linear.

Embodiment 3

[0055] Such as Figure 5 , Figure 7 and Figure 8 As shown, in addition to the features described in the above embodiments, it is further defined that: the slide rail assembly 12 includes two mounting seats 123, and the two mounting seats 123 are respectively slidingly connected with the first rail 121, and the two drilling machines 131 are connected with the first rail 121. The two installation bases 123 are correspondingly connected, and the installation base 123 moves along the first rail 121 to make the drilling machine 131 connected thereto move. In this way, the sliding connection between the drilling machine 131 and the first slide rail is realized through the mounting seat 123, so that the connection between the drilling machine 131 and the first slide rail is more stable and reliable.

[0056] Further, as Figure 6 , Figure 11 and Figure 12 As shown, the mounting base 123 is provided with a plurality of pulleys 124 , the first track 121 is provided with a pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com