Hydraulic fully-mechanized mining fault rock drilling equipment

A kind of rock drilling equipment and fault technology, applied in the field of hydraulic fully mechanized fault rock drilling equipment, can solve the problems of low operation efficiency, low hole layout efficiency, low production efficiency, etc., achieve convenient installation and disassembly, improve production efficiency, and save labor cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

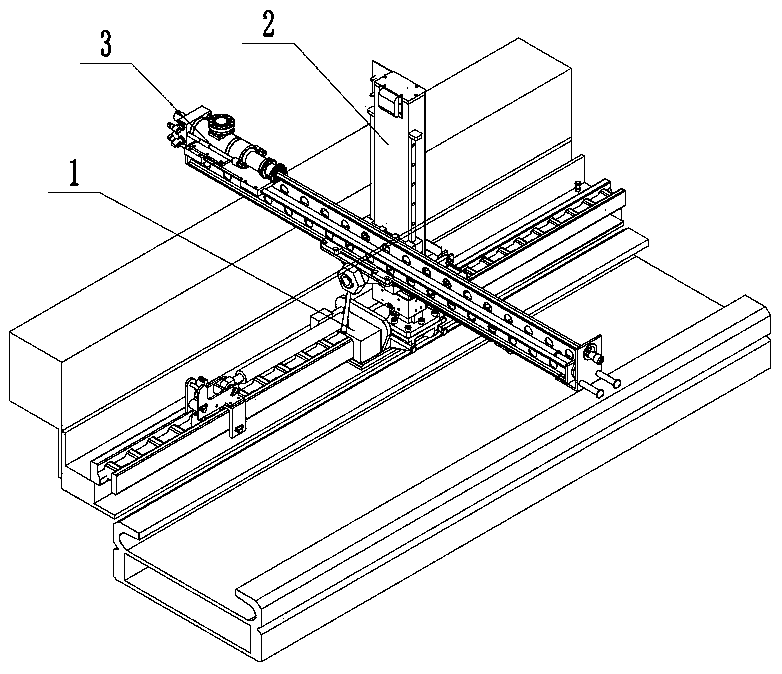

[0022] Such as figure 1 The hydraulic fully mechanized fault rock drilling equipment shown is composed of a traveling part, a two-stage lifting part, a propulsion part, and a hydraulic pump station. The running part is installed on the rack of the underground conveyor, the two-stage lifting part is fixed on the running part 1, the propulsion part 3 is connected with the two-stage lifting part 2 through the drill arm hanging plate 304, and the hydraulic pump station 4 is connected to the traveling part through the oil tank connecting plate 401. Part 1 is connected.

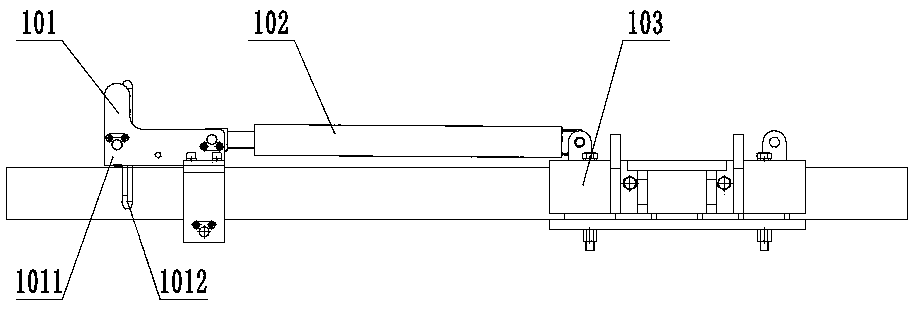

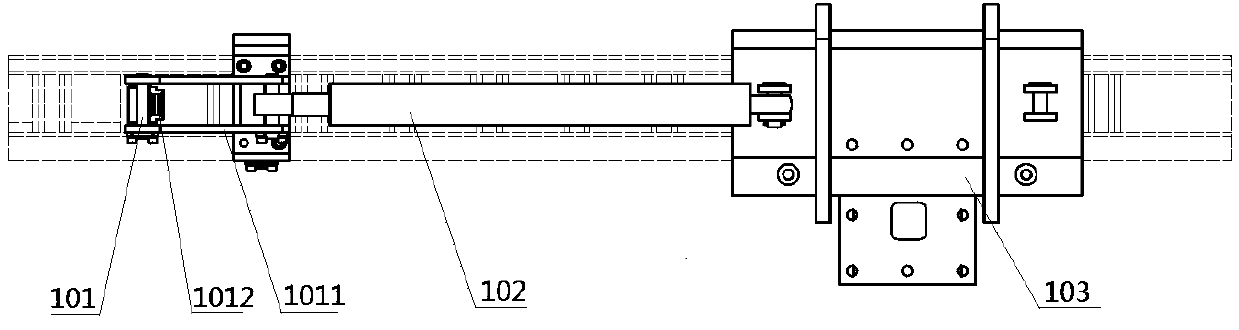

[0023] The structure of the walking part is as figure 2 As shown, it consists of two-way stopper seat, telescopic oil cylinder I, and main engine base. The two-way stopper is composed of an auxiliary base and an auxiliary baffle. The auxiliary baffle is connected to the auxiliary base through a connecting pin, so that the auxiliary baffle can swing in both directions, thereby realizing that the two-way stopper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com