Multi-hoisting point two-dimensional transmission automatic rope arranging compound crane

A multi-suspension, composite technology, applied in the direction of the spring mechanism, the hoisting device, etc., can solve the problem of the inability to install the stage boom, and achieve the effect of saving the structure cost and equipment cost, reducing the cost and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

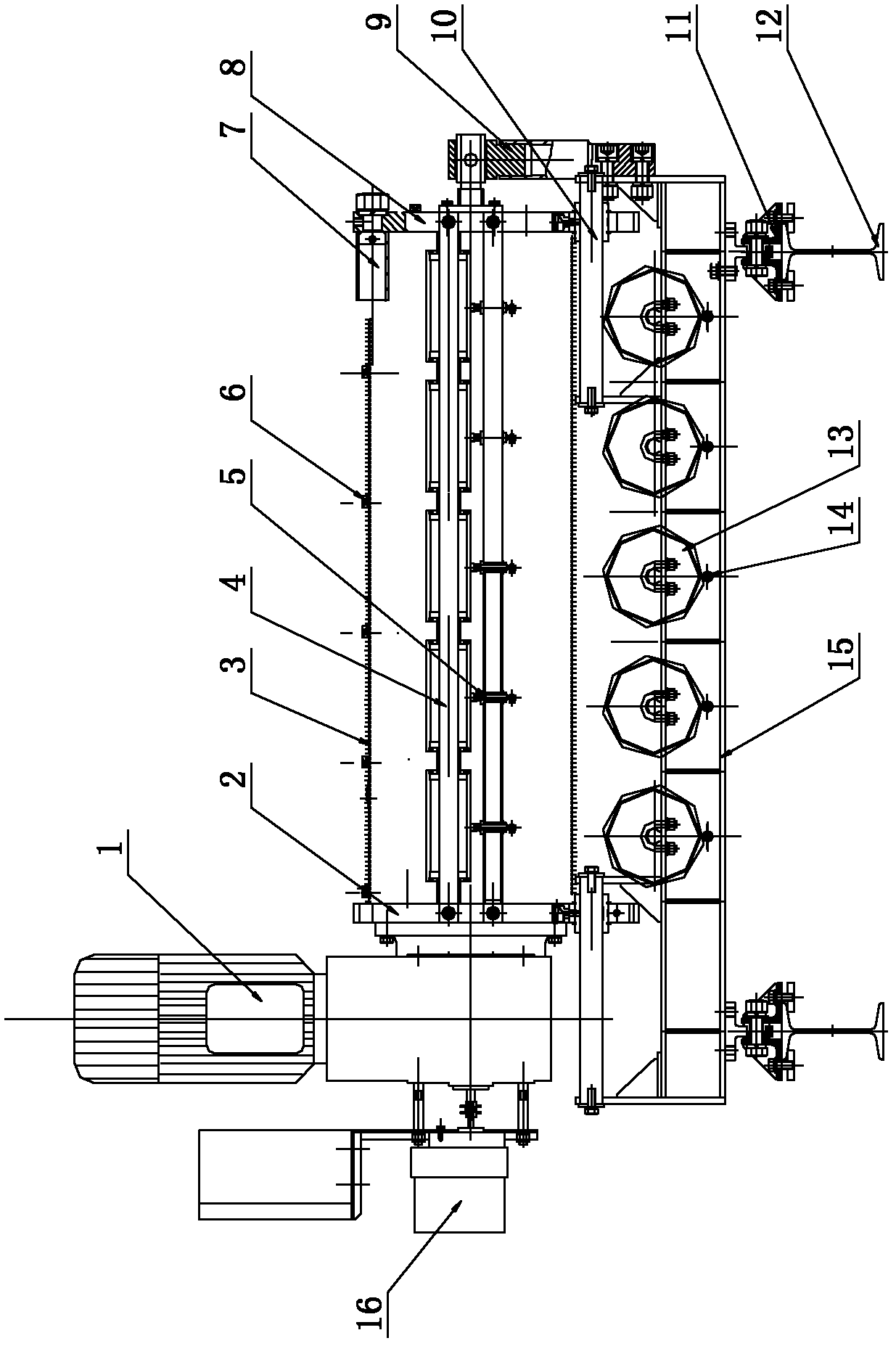

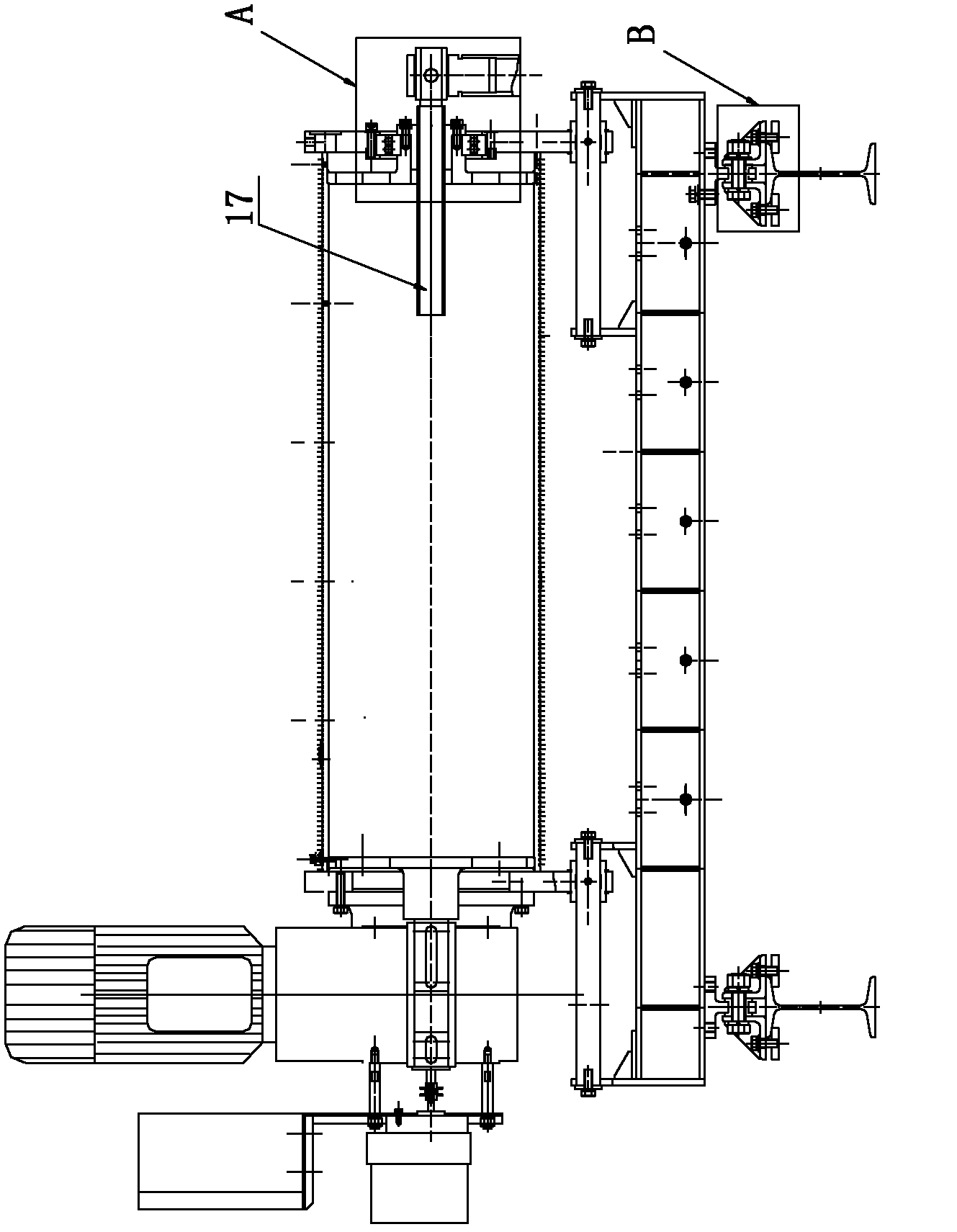

[0030] A multi-suspension two-dimensional transmission automatic rope-draining composite crane, including a support 11, a frame 15, a deceleration brake motor 1, and a rope-draining drum 3. The support is symmetrically fixed on the lower part of the frame, and the deceleration brake The output shaft of the motor drives the rotation of the rope arranging drum.

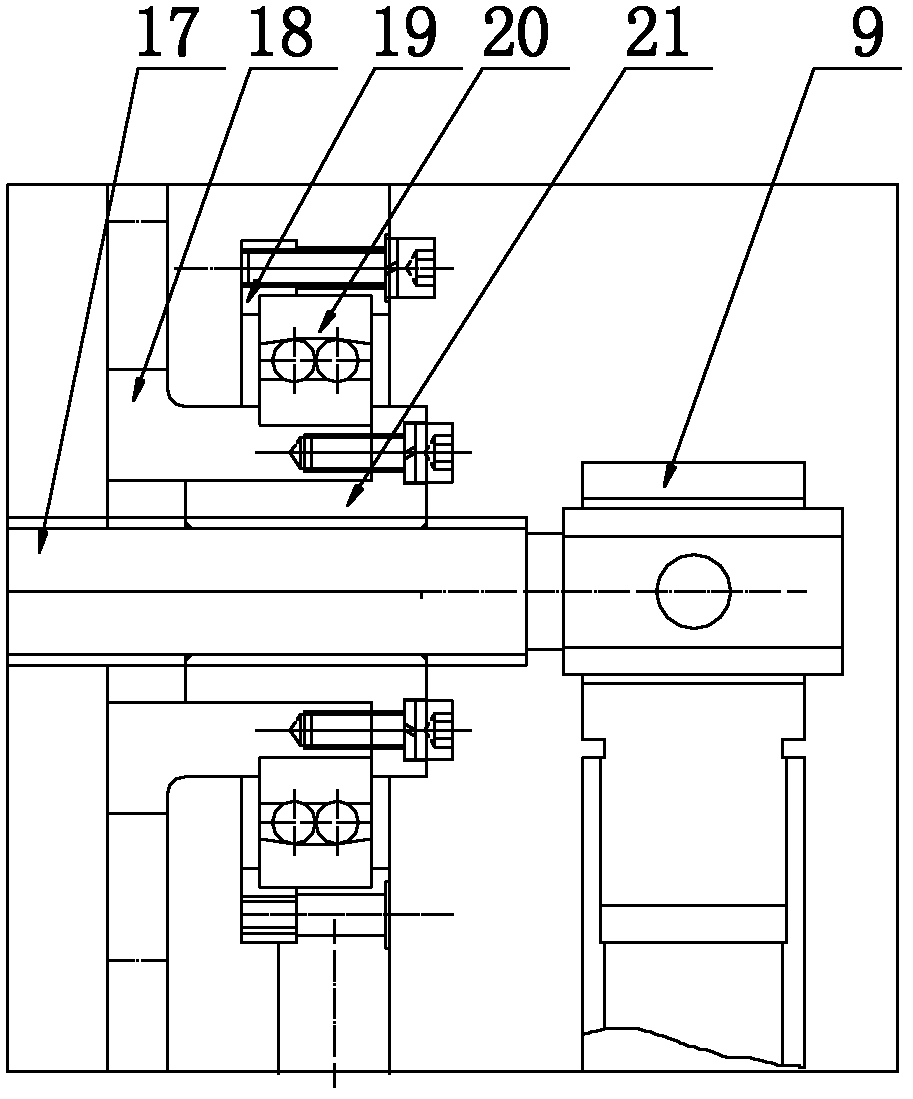

[0031] The innovation of the present invention is: the two ends of the rope-rowing drum are rotatably installed between the left supporting wallboard 2 and the right supporting wallboard 8, and the two supporting wallboards are fixed by the pull rods 7 located symmetrically outside the rope-rowing roller. The rope clamps 6 are arranged and arranged on the pull rods. The brake motor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com